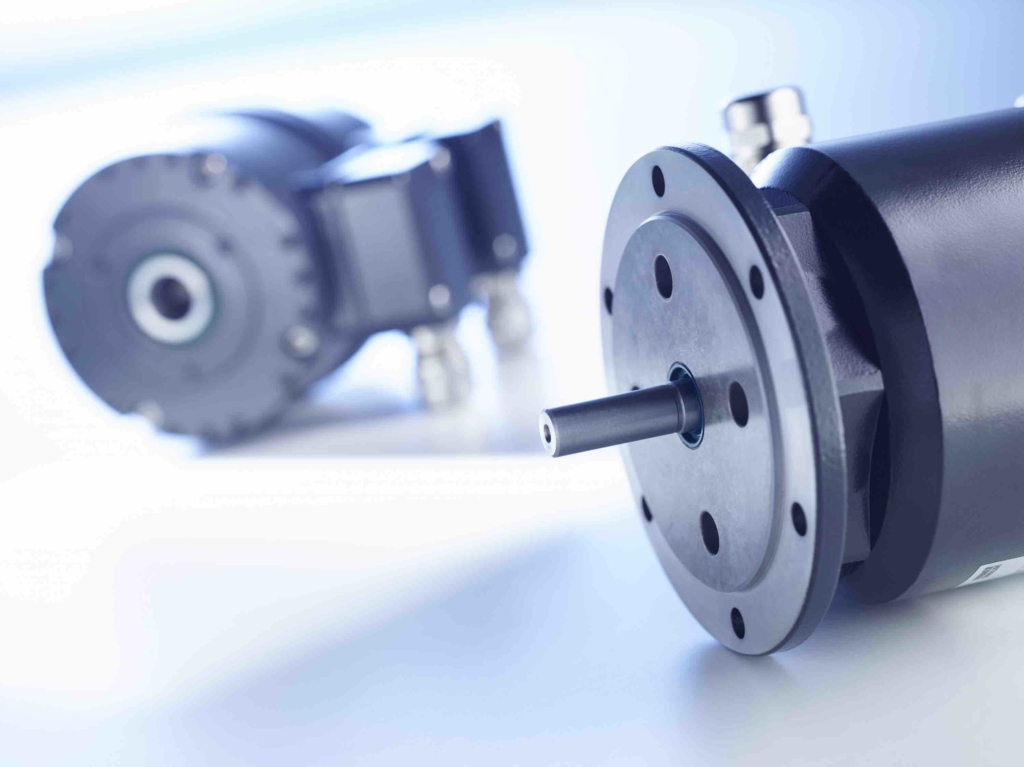

Baumer HeavyDuty encoders for construction equipment

The sophisticated sealing principle of Baumer HeavyDuty encoders is compliant with IP66 and IP67 standards over a wide temperature range up to +95°C. Thanks to a smart combination of labyrinth seals and sealing devices, the HeavyDuty encoders boast durable protection against all types of dirt: solid, wet and pasty. Baumer HeavyDuty encoders: designed to withstand […]

The sophisticated sealing principle of Baumer HeavyDuty encoders is compliant with IP66 and IP67 standards over a wide temperature range up to +95°C. Thanks to a smart combination of labyrinth seals and sealing devices, the HeavyDuty encoders boast durable protection against all types of dirt: solid, wet and pasty.

Baumer HeavyDuty encoders: designed to withstand

The definition of HeavyDuty, as a matter of fact, indicates something designed to withstand heavy-duty use, clearly indicating particular qualities of robustness and tenacity.

A HeavyDuty encoder must also meet several criteria, the first of which is accuracy: the accuracy of the measurement signals produced by a HeavyDuty encoder must be identical to that of a smaller device. It is through these signals that the control units of the systems detect the speed of an engine or the position of a machine component.

Only in this way can the control unit may intervene appropriately if an engine is running above or below a certain speed. Even a small measurement error can have severe consequences and, in the case of transporting loose goods, cause damage to the system.

Fail-safe technology

Alongside precision, reliability is another key factor. In order for an encoder to do its job under the difficult conditions of an open-cast mine and a port in a reliable manner, it must be able to withstand strong shocks, vibrations and other forces on the shaft for many years without loss of accuracy.

TWO EXAMPLES OF CONTINUITY IN OIL & GAS

Robustness is therefore a watchword not only mechanically, but also electrically. In fact, electromagnetic fields are often generated near encoders, associated for example with unshielded current conductors. Without sufficient shielding, the encoder electronics can suffer irreparable damage or rather be subject to interference that can, however, compromise the quality of the measurement signals.