Bosch Rexroth is ready to Agritechnica 2025

At Agritechnica 2025 the Bosch Rexroth focus won't be on BEV applications. With HydraForce it will Present Modular Hydraulic Solutions for the Agricultural Machine

The central focus of Bosch Rexroth’s presence at bauma was electrification. This is a hot topic that has lost some momentum in recent months. What will we see at Agritechnica 2025? Bosch Rexroth and HydraForce will showcase a range of modular hydraulic solutions designed to help agricultural machinery manufacturers. We anticipate that even at the German stand, we will witness a return to the past, riding the wave of the recent relaunch of the internal combustion engine and hydraulics technologies.

Rexroth and HydraForce

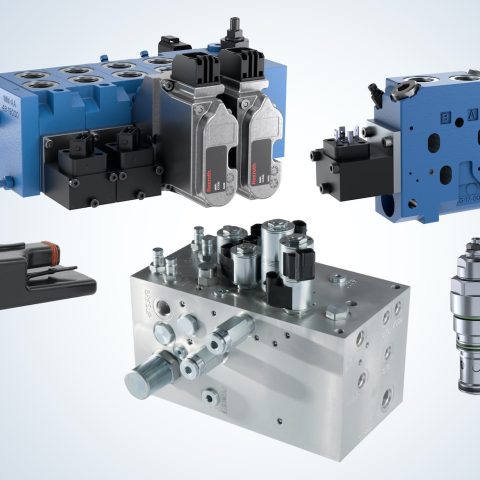

The first one we mention is the EDG-OBE compact directional valve, a solution designed for tight spaces and high-precision applications, including harvesters and agricultural implements. With integrated onboard electronics, the EDG-OBE offers precise spool control, simplified wiring and plug-and-play functionality, making it an ideal choice for OEMs looking to combine performance and safety in a compact package.

According to Bosch Rexroth, the EDH-OBE compact directional valve offers high flow capacity and a wide range of configuration options, making it ideal for complex machinery like self-propelled agricultural working machines and advanced implements. OEMs can tailor the system with anti-shock and anti-cavitation valves, manual actuation, local pressure control, LSA/LSB options and more.

TS90-G34L valve and HF-Impulse 2.0 software

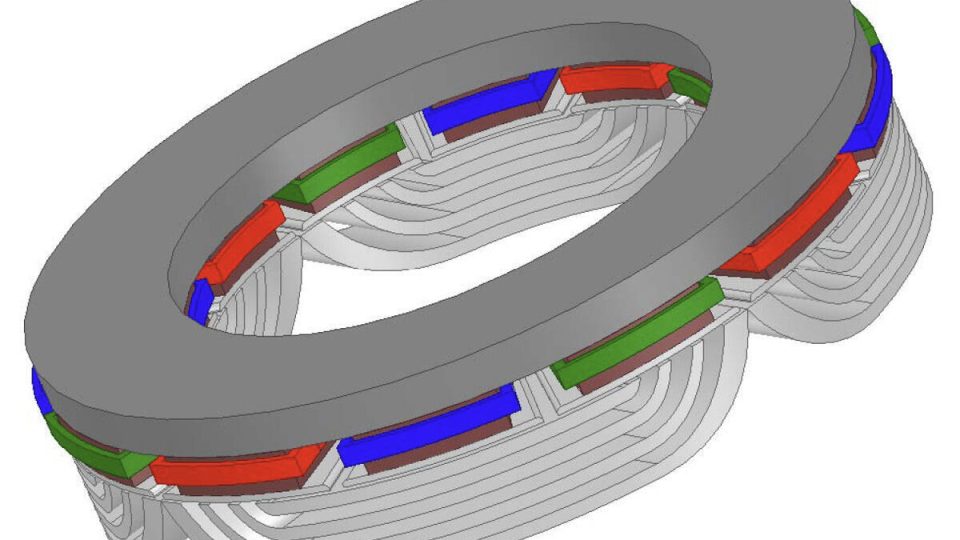

HydraForce’s patented TS90-G34L is a pilot-operated proportional pressure reducing/relieving valve for powershift transmissions with multiple clutches. By reducing pilot flow by up to 75% compared to conventional designs, the valve enables smaller pumps, lowers energy consumption and cuts operational costs.

Thanks to its two-stage operation, the TS90-G34L delivers smoother gear shifting and more precise control over pressure and flow, with improved damping and reduced sensitivity to temperature or viscosity variations. Its low-leakage design minimizes energy consumption, offering a tangible optimization of the system. Over time, the impact is significant: annual energy savings per valve can reach 90%, dramatically reducing both fuel consumption and CO2 emissions

HF Impulse 2.0 HydraForce’s software development and configuration tool for ExDR controllers, complements the hardware offer with a powerful and intuitive software platform. The tool supports both graphical and text-based programming, enabling complex control logic with simplified coding. It simplifies work for developers and application engineers alike, reducing time to validation and accelerating series production.