Chalmers University and the massless energy storage

A research group at Chalmers University of Technology in Sweden is now presenting a world-leading advance in so-called massless energy storage – a structural battery that could halve the weight of a laptop.

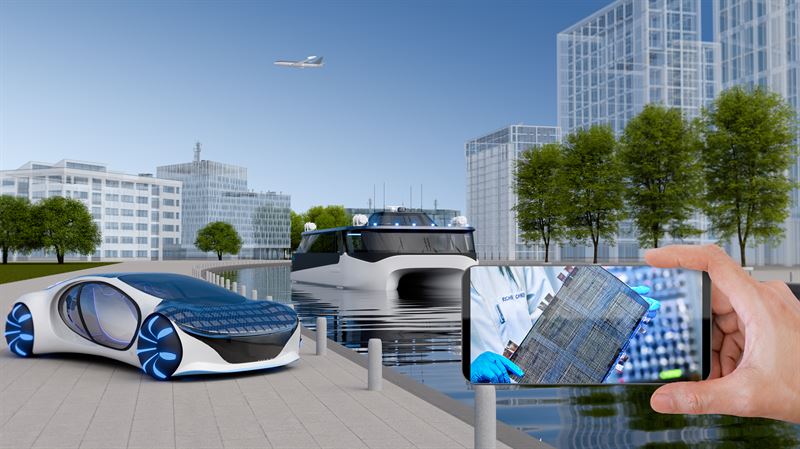

A research group at Chalmers University of Technology in Sweden is presenting a world-leading advance in so-called massless energy storage – a structural battery that could halve the weight of a laptop, make the mobile phone as thin as a credit card or increase the driving range of an electric car by up to 70 percent on a single charge.

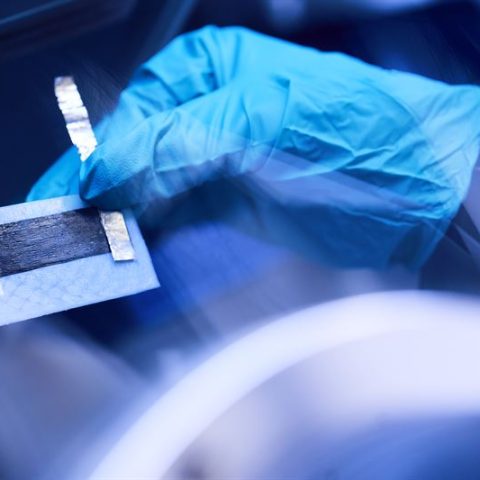

“We have succeeded in creating a battery made of carbon fibre composite that is as stiff as aluminium and energy-dense enough to be used commercially. Just like a human skeleton, the battery has several functions at the same time,” says Chalmers researcher Richa Chaudhary, who is the first author of a scientific article recently published in Advanced Materials.

Research on structural batteries has been going on for many years at Chalmers, and in some stages also together with researchers at the KTH Royal Institute of Technology in Stockholm, Sweden. When Professor Leif Asp and colleagues published their first results in 2018 on how stiff, strong carbon fibres could store electrical energy chemically, the advance attracted massive attention. The news that carbon fibre can function as electrodes in lithium-ion batteries was widely spread and the achievement was ranked as one of the year’s ten biggest breakthroughs by the prestigious Physics World.

Read also: Chalmers University to improve fuel cell vehicles

Lower weight requires less energy

Since then, the research group has further developed its concept to increase both stiffness and energy density. The previous milestone was reached in 2021 when the battery had an energy density of 24 watt-hours per kilogramme (Wh/kg), which means roughly 20 percent capacity of a comparable lithium-ion battery. Now it’s up to 30 Wh/kg. While this is still lower than today’s batteries, the conditions are quite different. When the battery is part of the construction and can also be made of a lightweight material, the overall weight of the vehicle is greatly reduced. Then not nearly as much energy is required to run an electric car, for example.

“Investing in light and energy-efficient vehicles is a matter of course if we are to economise on energy and think about future generations. We have made calculations on electric cars that show that they could drive for up to 70 percent longer than today if they had competitive structural batteries,” says research leader Leif Asp, who is a professor at the Department of Industrial and Materials Science at Chalmers.

When it comes to vehicles, of course, there are high demands on the design to be sufficiently strong to meet safety requirements. There, the research team’s structural battery cell has significantly increased its stiffness, or more specifically, the elastic modulus, which is measured in gigapascal (GPa), from 25 to 70. This means that the material can carry loads just as well as aluminium, but with a lower weight.

“In terms of multifunctional properties, the new battery is twice as good as its predecessor – and actually the best ever made in the world,” says Leif Asp, who has been researching structural batteries since 2007.

Several steps towards commercialisation

From the start, the goal was to achieve a performance that makes it possible to commercialise the technology. In parallel with the fact that the research is now continuing, the link to the market has been strengthened – through the newly started Chalmers Venture company Sinonus AB, based in Borås, Sweden.

However, there is still a lot of engineering work to be done before the battery cells have taken the step from lab manufacturing on a small scale to being produced on a large scale for our technology gadgets or vehicles.