Purem ATS by Eberspaecher

The Purem by Eberspaecher plant in Wilsdruff converted the production line for exhaust gas aftertreatment systems

The Purem by Eberspaecher plant in Wilsdruff, Germany, converted the production line for exhaust gas aftertreatment systems for the European market of a commercial vehicle manufacturer to sustainable stainless steel. The material used is Outokumpu’s towards-zero stainless steel called “Circle Green”.

The Purem factory close to Dresden

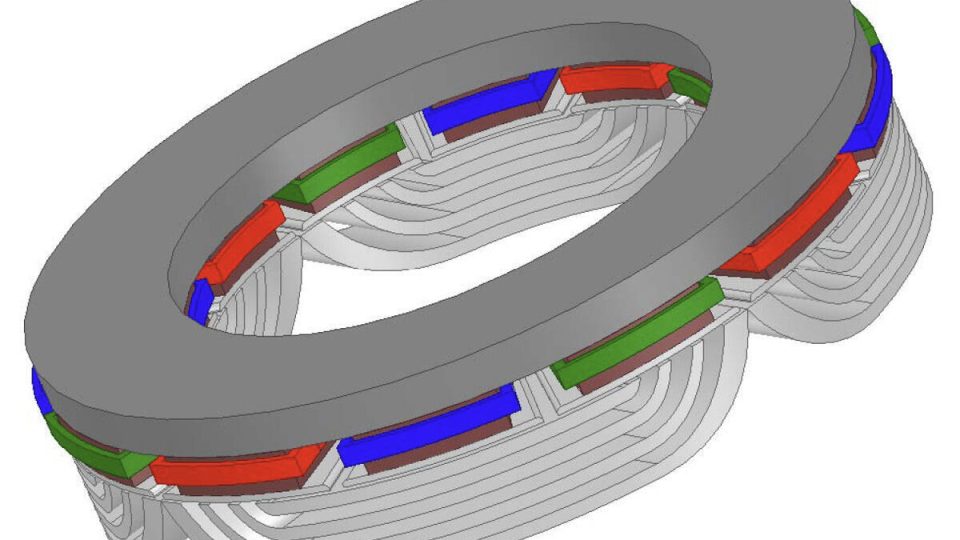

The first exhaust gas aftertreatment systems made from sustainable stainless steel rolled off the production line at the Purem by Eberspaecher plant in Wilsdruff near Dresden, already in summer 2023. As part of a pilot project, around 90 percent of the most common steel grade used in the production line of one of the leading commercial vehicle manufacturers has been converted since the beginning of 2025.

By the end of this year, the inner and outer shells as well as the insulation will be adapted to the new material. Therefore, Outokumpu Circle Green, with up to 93 percent lower carbon footprint than the global industry average, is utilized for the majority of exhaust technology components in series production for the European market.

(Outokumpu’s average product carbon footprint (2024): 1.6 kg CO2e per kg of stainless steel based on lifecycle assessment. Global average carbon footprint of stainless steel (2024): 7 kg CO2e per kg of stainless steel. (Outokumpu’s calculation based on data provided by CRU, worldstainless, and Kobolde & Partners AB)

The systems are installed in medium- and heavy-duty vehicles like trucks, buses and construction machinery. Using the stainless steel alternative is an important step towards reducing Purem by Eberspaecher’s Scope 3 emissions.

Sustainable Stainless Steel

Circle Green is produced at Outokumpu’s plant in Tornio, Finland, and then delivered to Purem by Eberspaecher plant in Wilsdruff, Germany. Outokumpu’s Circle Green production was the first of its kind globally, as no other manufacturer has been able to produce CO2-reduced stainless steel with such low emission levels when taking into account all the climate emissions from raw material extraction throughout the whole production chain.

“The future of low-carbon solutions is heavily dependent on sustainable steel. The global demand is increasing while the steel industry as a whole is responsible for 10 percent of global greenhouse gas emissions. Stainless steel plays a pivotal role in accelerating the green transition and the automotive sector is one of where all solutions to cut emissions are heavily needed. We are proud to continue our collaboration with Purem by Eberspaecher, offering solutions for both passenger cars and commercial vehicles. The cooperation is yet another concrete action towards low-emission mobility in Europe,” says Matthieu Jehl, President for Stainless Europe at Outokumpu.