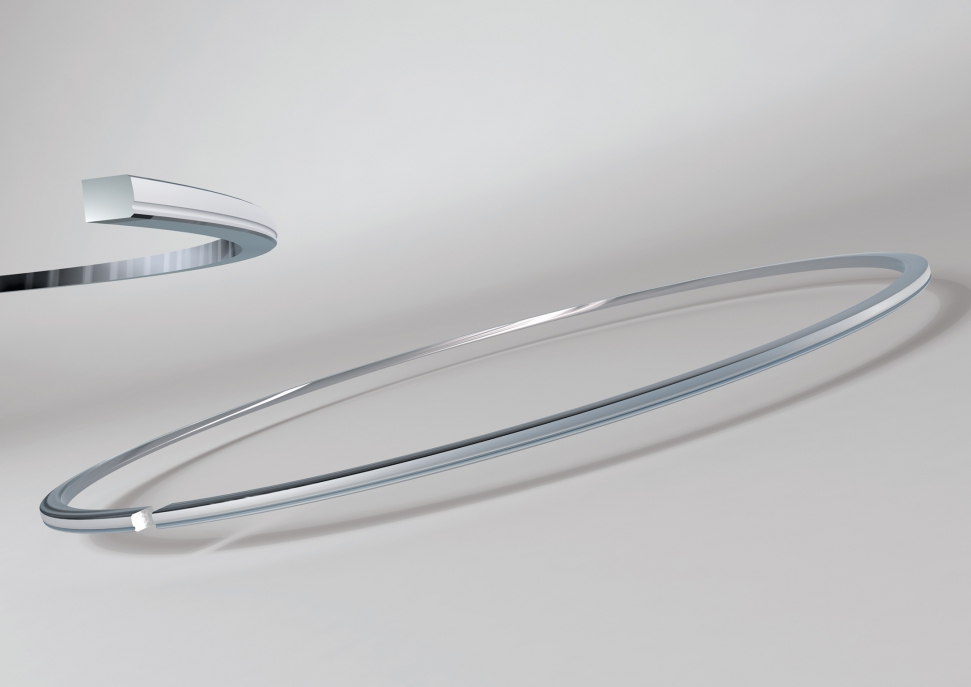

Federal-Mogul. New elastic band eLine

Federal-Mogul eLine. For commercial and industrial applications Federal-Mogul Powertrain has just launched a new elastic band called eLine designed specifically for diesel engines for commercial and industrial vehicles. The main advantage that eLine offers is to minimize gas leakages. The dynamic movement of the band remains stable throughout time. The homogeneity of the oil film […]

Federal-Mogul eLine. For commercial and industrial applications

Federal-Mogul Powertrain has just launched a new elastic band called eLine designed specifically for diesel engines for commercial and industrial vehicles. The main advantage that eLine offers is to minimize gas leakages. The dynamic movement of the band remains stable throughout time. The homogeneity of the oil film benefits from this feature of eLine.

The improvements depend in the first instance on the design of the profile of the sliding surface of the band that fits into the second spline. In fact, the design allows a more uniform distribution of the oil around the cylinder, and the sliding face area has been modified to reduce the effect of gas pressure.

Stability and homogeneity of the oil with eLine

Typically, the elastic bands for commercial and industrial vehicles going into the second spline have sliding face conical profile. This allows keeping the oil film homogeneous even under non-optimal conditions. This is the case, for example, of when bore distortion or problems in the supply of oil occur. However, having the conical profile also means having a sliding face with a large surface. This in turn can generate radial instability of the band when a pressure imbalance is created between the inside and outside diameter of the band.

Steffen Hoppe, Director, Technology, Rings & Liners, Federal-Mogul Powertrain, illustrated the advantages of the new range. «eLine is the first technology for elastic bands of commercial and industrial vehicles that guarantees the distribution of the oil in a uniform layer along the circumference. The geometry balances localized excesses of oil drop and protects against local oil decompositions. Besides, it supports strategies with low viscosity oils, improves gas tightness and reduces wear. The specific profile of the sliding surface has also been designed to prevent radial instabilities of the band, more and more present due to the tendency to have higher peak pressures during combustion». This translates primarily into a greater efficiency of the whole engine. On the other hand, it also means getting advantages in terms of lower emissions and greater robustness.

The new geometry and the proof of the facts

The new band has a groove along the lower part of the circumference. This helps to retain excess oil below the band. This generates a difference in circumferential pressure thanks to the oil in this grooved tank. In turn, the pressure gives rise to a controlled flow of oil around the cylinder when the piston reverses its motion. Thus the film’s uniformity benefits. At a hydrodynamic level, the profile of the sliding surface contributes to reducing the area for pressurized gases towards the upper part of the band.

Federal-Mogul conducted bench tests of the eLine range, which showed a reduction of up to 20% of the “blow-by” phenomenon. This occurs when the gases in the combustion chamber reach the maximum pressure. In these situations part of them exceeds the elastic bands reaching the lower part of the monoblock. In other words, we obtain an increase in the average effective pressure. To say it in another term, you can achieve a decrease in consumption.