GlideValve Engine Technology and its camless valvetrain concept

GlideValve camless valvetrain design can work on all kinds of engines GlideValve is working on an innovative camless valvetrain concept to answer the call of the automotive industry that continues to look at new ways to meet tightening regulations. Tested on a single cylinder prototype engine and designed for proof-of-concept and efficiency, the system requires […]

GlideValve camless valvetrain design can work on all kinds of engines

GlideValve is working on an innovative camless valvetrain concept to answer the call of the automotive industry that continues to look at new ways to meet tightening regulations.

Tested on a single cylinder prototype engine and designed for proof-of-concept and efficiency, the system requires a comparative piston size and airflow to most car and truck engines. This means that GlideValve designs can work with two-, four-, six- and eight-cylinder applications. Based on the analysis obtained by a nationally recognized testing facility, GlideValve could enable more efficient operation than traditional poppet valves.

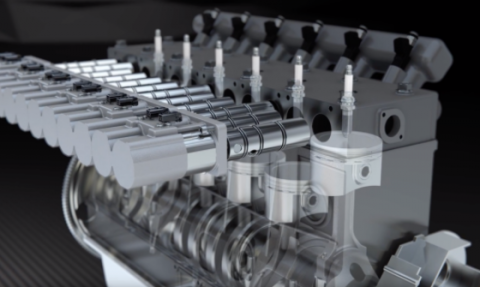

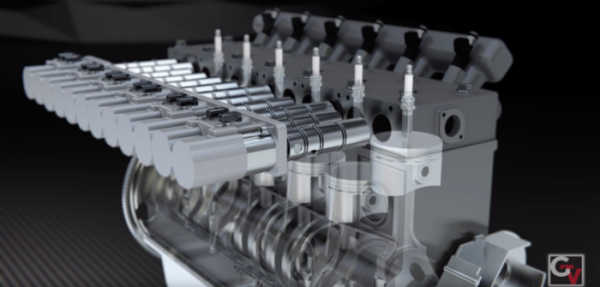

Engineers have spent plenty of time on valve trains. And while they have made great strides, the fundamental problem still exists: the poppet valve is simply not the best for the job. Recent improvements have succeeded in making valves open and close quickly but at the cost of complexity. The top half of a modern overhead cam engine is a busy, crowded place filled with valves, springs, seals, gaskets, bearings and more. It works reasonably well, but at the cost of higher complexity.

This is where the new solution steps in…

GlideValve eliminates virtually all traditional valve gear. Instead of a complicated OHC system, each GlideValve, covering both intake and exhaust, has just two moving parts when connected to an actuator. Instead of a towering camshaft and multiple poppet valve arrangement, this solution keeps a low profile that drastically lowers engine height. GlideValve moves air through the interior of the valve, and seals the valve with rings around the exterior of the valve. This tubular design allow the valve to open and close without the need of entering the combustion chamber like the poppet valve. This design advantage allows two glide valves to move more air per cylinder than four poppet valves.

The ability to alter engine timing, without the fear of valve or piston collision, can achieve 30% greater efficiency. Also, there can be a reduction in terms of emissions through complete fuel combustion, thanks to zero valve overlap. GlideValve can be retrofitted for head-only, or it can be added to an existing engine block without engine compartment infrastructure modification. The head and block can also come as one piece, so no head bolts or head gaskets are necessary.