Impact launches new automated line to double battery production (up to 1.2 GWh) in 2024

Polish battery systems make Impact Clean Power Technology has launched what the company claims being “Europe’s most modern, highly automated” lithium-ion battery production line. The new line, designed and manufactured by Teamtechnik, will allow the company to increase its generating capacity from 0.6 to 1.2 GWh in 2024, and ultimately to up to 4 GWh

Polish battery systems make Impact Clean Power Technology has launched what the company claims being “Europe’s most modern, highly automated” lithium-ion battery production line. The new line, designed and manufactured by Teamtechnik, will allow the company to increase its generating capacity from 0.6 to 1.2 GWh in 2024, and ultimately to up to 4 GWh.

Up to now, the company has supplied the market with 12,000 battery packs for 4,200 e-buses. Among the key partner of Impact there’s Solaris.

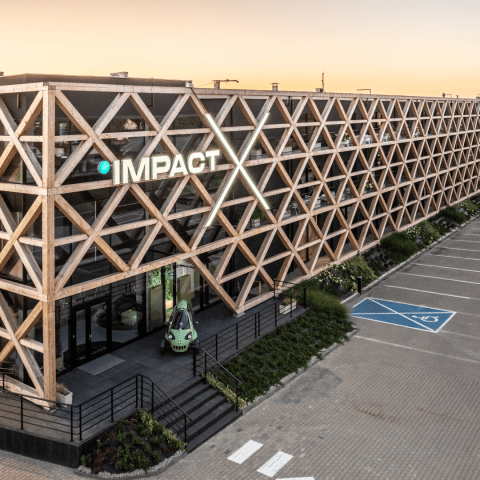

With its launch, Impact has completed the investment in its new headquarters, GigafactoryX, which, in addition to production, houses the company’s key functions such as R&D, test laboratory and warehouse. All in the city of Pruszków, near Warsaw.

Impact launches new production line for batteries

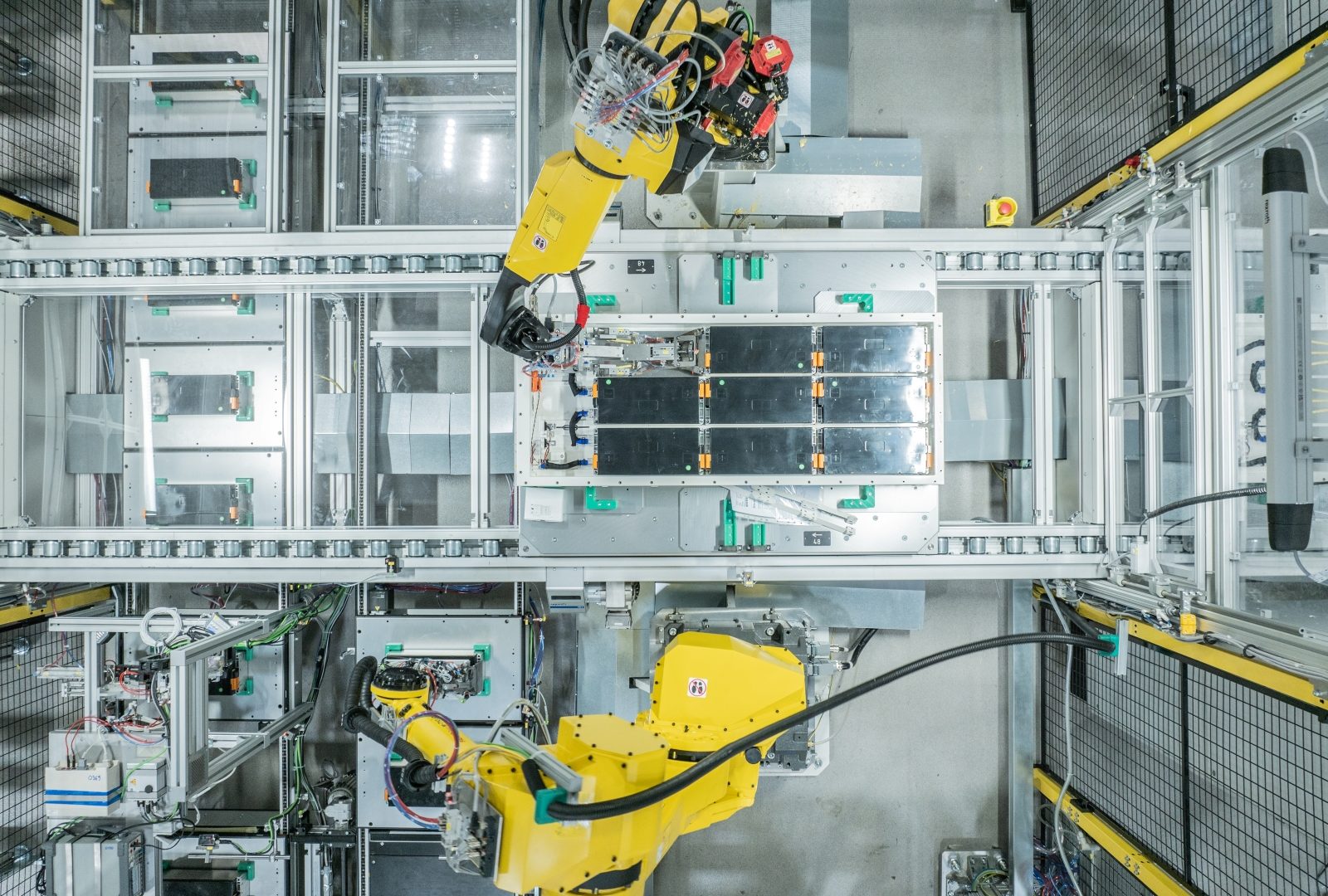

The new highly automated production line will increase Impact’s production capacity from 2,500 to at least 16,000 lithium-ion batteries per year. This means that a complete battery system dedicated to heavy transport will be made every 11 minutes, the supplier states.

The line structure consists of 22 stands and covers an area of 1,375 m² and uses the TS7 conveyor system from Bosch Rexroth, which can handle batteries with dimensions of 1.8 m x 0.5 m x 0.5 m and a maximum weight of up to 1 tonne (the average weight of a single battery is around 300 kg.). The flex-type line makes it possible to produce different battery sizes simultaneously and it is scalable.

The full serialisation of the production process guarantees a digital record of every operation, allowing for precise tracking of components and process parameters. Automation includes assembly, batching, bolting, vision inspection and a range of tests, ensuring consistent product quality. The system, Impact stresses, also allows batteries to be evacuated at any stage of production, offering a very high level of safety.

The new line meets the requirements for IATF 16949:2016 certification, received by Impact in 2024.

“At Impact, we have spent years perfecting our battery systems for heavy transport, which stand out in the market for their unparalleled energy density and high level of safety. These are complemented by our proprietary BMS, which ensures maximum integration and optimisation of the entire system’s performance, and protects it from the latest threats,” said Ireneusz Kazimierski, CEO of Impact Clean Power Technology. “Thanks to Impact’s state-of-the-art production line and increased capacity, we will be able to deliver our advanced solutions to more customers, which will allow us to execute the company’s ambitious growth plans”.

“With the launch of the new production line at GigafactoryX, we have joined the ranks of lithium-ion battery gigafactories, opening a new chapter in IMPACT’s history,” said Ninoslav Sotirov, Vice President of Impact Clean Power Technology. “This will enable us to fulfil large-scale orders, providing customers with products with exceptional technical parameters, manufactured to the highest standards of modern production,” added Ninoslav Sotirov.