MAN Engines: increased efficiency in turbocharged natural gas engines with pre-chamber spark plugs

MAN Engines is now offering all turbocharged natural gas engines of the current MAN E3262, E3268, E0836 and E0834 series as an option, as well as MAN E3872 obligatory with pre-chamber spark plugs adapted to the respective combustion chamber.

MAN Engines is now offering all turbocharged natural gas engines of the current MAN E3262, E3268, E0836 and E0834 series as an option, as well as MAN E3872 obligatory with pre-chamber spark plugs adapted to the respective combustion chamber.

Due to backward compatibility, existing combined heat and power plants (CHP) with the aforementioned twelve, eight, six and four-cylinder engines can also be retrofitted with pre-chamber spark plugs using the lean combustion process. This includes operation with hydrogen-containing fuels with up to 20% hydrogen admixture. A conversion of the engines is not necessary for the use of pre-chamber spark plugs. Due to the software adjustment of the ignition timing and the reduction of the energy requirement, less powerful ignition control units may be necessary.

The pre-chamber spark plugs are approved for operation at both 500 mg/Nm3 NOx and 250 mg/Nm3 (at 5% O2), which complies with the 44th Ordinance on the Implementation of the Federal Immission Control Act (BImSchV) in Germany. “With the approval of our turbocharged natural gas engines for the use of pre-chamber spark plugs, we are offering our customers higher efficiency and lower maintenance requirements as added value,” says Reiner Roessner, Head of Sales MAN Engines.

Especially in low-NOx applications, the pre-chamber spark plug offers some significant advantages over the conventional spark plug. A clear advantage of pre-chamber spark plugs is their longer service life, which is influenced, among other things, by the lower ignition energy. “Our measurements have shown that we can multiply the service life in low-NOxapplications with pre-chamber spark plugs. This is a definite plus in terms of reducing maintenance costs,” says Werner Kübler, Head of Engineering at MAN Engines.

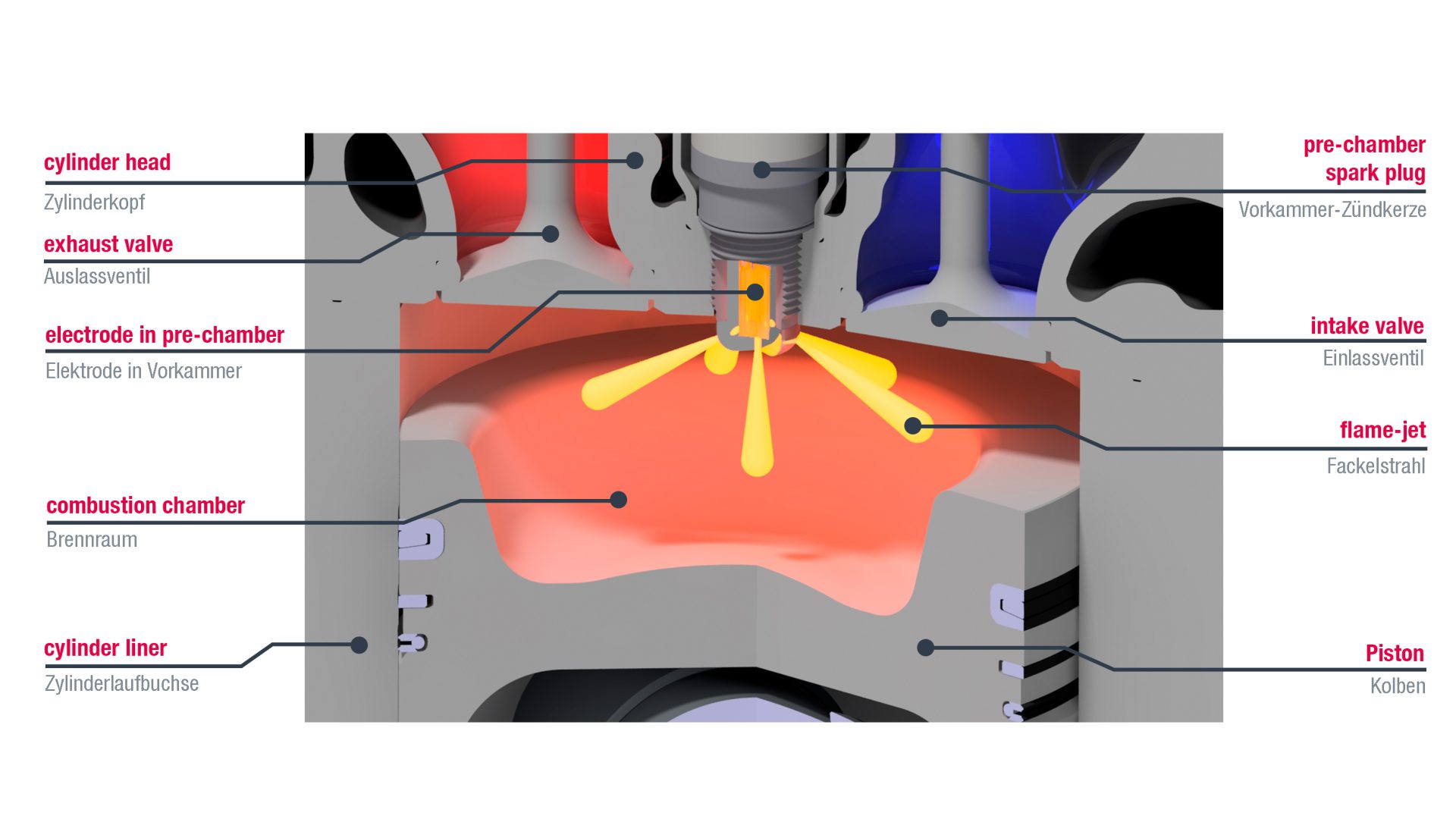

In addition, MAN engines with pre-chamber spark plugs offer better combustion quality: the pre-chamber spark plug is equipped with radially arranged holes, which provides a connection to the main combustion chamber. During the piston upward movement during the compression phase, the gas-air mixture enters the pre-chamber via the holes, where it is ignited. Due to the structural and structural design, the fuel gas-air mixture in the main combustion chamber can be better ignited by the escaping high-energy flame jets of the pre-chamber and thus lean mixtures can be safely ignited. The optimal ignition in the prechamber is realized by several ignition sources arranged in a star shape. “With pre-chamber spark plugs, we can improve the efficiency of a system by up to one percentage point,” says Kübler.

Another advantage of pre-chamber spark plugs is their greater flexibility in terms of ignition conditions. The pre-chamber spark plug can control the ignition of the fuel-air mixture better than a conventional hook spark plug, thus ensuring increased smoothness and smoothness.