Danfoss and Emissions Analytics

At the Emissions Analytics Non-Road Powertrain & Fuels Europe 2025 event, Danfoss outlined its approach to reducing emissions in mobile machinery through efficiency, advanced hydraulics, and electrification, aiming for fully emission-free drivetrains

While speaking at the event for industry professionals organized by Emissions Analytics, Danfoss Power Solutions claimed to be focused on efficiency as the foundation for decarbonising mobile machinery. The company’s broad product portfolio—covering hydraulic components, control systems, hoses, and electric elements—supports OEMs in improving drivetrain performance and progressing toward low- and zero-emission operation.

Emissions under the Danfoss Power Solutions Lens

Decarbonisation in this sector is driven by a combination of regulation, corporate responsibility, and technical necessity. Low-emission zones in cities such as London and Amsterdam, together with sustainability pledges and the EU’s Corporate Sustainability Reporting Directive (CSRD), are pushing manufacturers to reduce their carbon footprint. Beyond compliance, Danfoss considers emission reduction a technical challenge that can be solved through better energy management across the drivetrain.

At the Non-Road Powertrain & Fuels Europe 2025 conference in Munich, Danfoss Power Solutions was represented by Andreas Schumacher, Head of Sustainability and Product Compliance. His presentation focused on “Decarbonization in Mobile Machinery – From Reducing Carbon Emissions to Emission-Free Drivetrains.”

A conventional hydraulic drivetrain is inherently inefficient. Of 100 kW generated by a diesel engine, around 60% is lost as heat and exhaust, while further losses occur in pumps, motors, and transmission. Overall drivetrain efficiency often averages below 35%, meaning only a fraction of the fuel energy reaches the wheels.

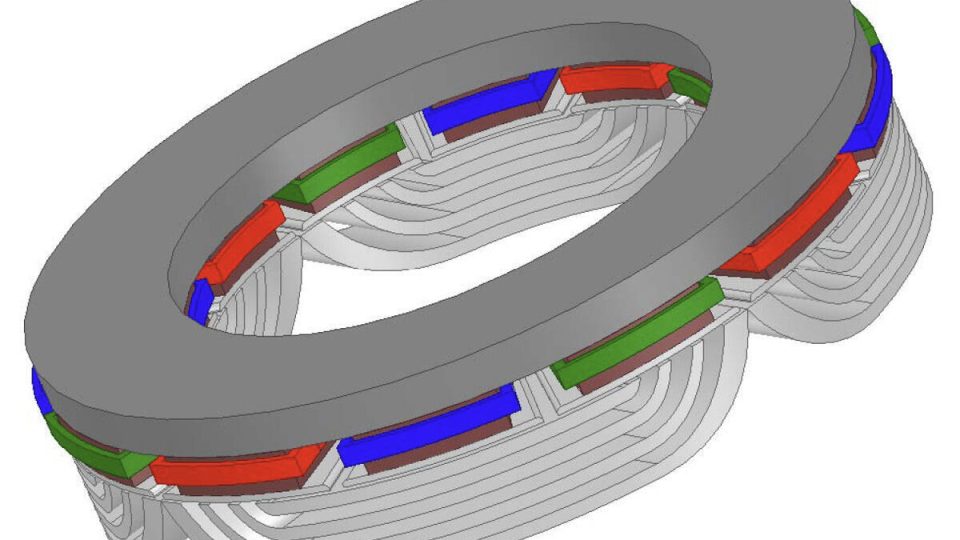

To address this, Danfoss applies a tiered optimisation strategy. At component level, switching from a traditional swashplate to a bent-axis motor can deliver 2–4 kW savings per drive line, avoiding roughly 40 tons of CO2e over 10,000 operating hours. At system level, the Digital Displacement Pump (DDP) allows individual pistons to be controlled independently, maintaining high efficiency even under partial load. When used in a dynamic manifold architecture, it can provide 25–30% fuel savings by avoiding throttling losses typical of conventional systems.

The link between efficiency and electrification

Efficiency gains multiply when combined with electrification. Diesel systems require roughly three times more energy input to perform the same work as an electric drivetrain. Using the IEA 2024 global grid average, an electric machine can reduce annual CO2 emissions by 40%, while an optimised system based on DDP architecture achieves up to 55%. In regions powered by renewables, such as Scandinavia, near-zero operational emissions are achievable, whereas grids dependent on coal, as in parts of India, reduce the benefit.

The decarbonisation potential grows with system complexity: from 40 tons CO2e savings at component level, to 110 tons with advanced hydraulic systems, and near elimination of emissions through full electrification.