Four MAN 175D engines selected for Svitzer tugs

Uzmar Shipyards in Turkey has placed an order for four of MAN’s latest variant 12V175D-MM marine propulsion engines for global tug operator, Svitzer. The new engines will provide the opportunity to run on HVO.

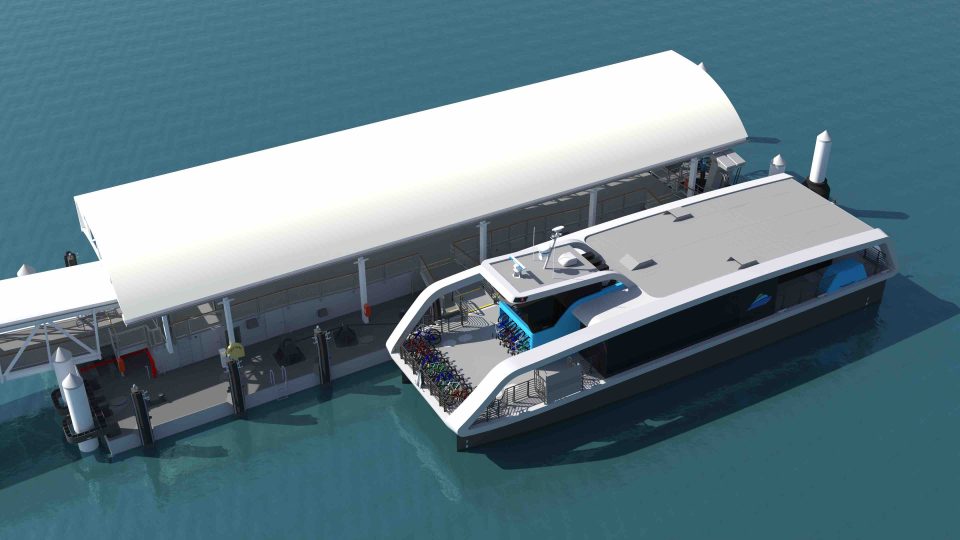

Uzmar Shipyards in Turkey has placed an order for four of MAN Energy Solutions’s latest variant 12V175D-MM marine propulsion engines for global tug operator, Svitzer. Each shipset consists of two 2,400 kW-rated engines and will provide mechanical propulsion power for the TRAnsverse tugs.

MAN Energy Solutions’ production facility in Frederikshavn, Denmark will supply the engines directly to Uzmar with deliveries respectively scheduled for November and December 2023, while vessel completions are planned for late 2024. Upon handover, the tugs will enter service as part of Svitzer’s Australian fleet.

As part of its decarbonisation strategy, Svitzer is gradually introducing new, low-emission fuel types into its operations. The new engines will provide the opportunity to run on HVO (Hydrotreated Vegetable Oil), which can bring tank-to-wake carbon emissions to zero.

Kasper Karlsen, Chief Operating Officer at Svitzer, said: “While always selecting engines that will be dependable in our diverse and often demanding marine-services operations many years into the future, the opportunities for decarbonisation are an equally important consideration. MAN Energy Solutions is a key provider for us in this context, and we are pleased to be partnering with them for the delivery of engines for our two new TRAnsverse tugs.”

Florian Keiler, Head of High Speed, MAN Energy Solutions, said: “This important order provides another clear example of the benefits of having compact 12-cylinder propulsion engines with this amount of power available for harbour tug applications. It also demonstrates the trust that global customers, such as Svitzer and Uzmar, place in MAN Energy Solutions to deliver the highest quality equipment with many significant performance benefits.”

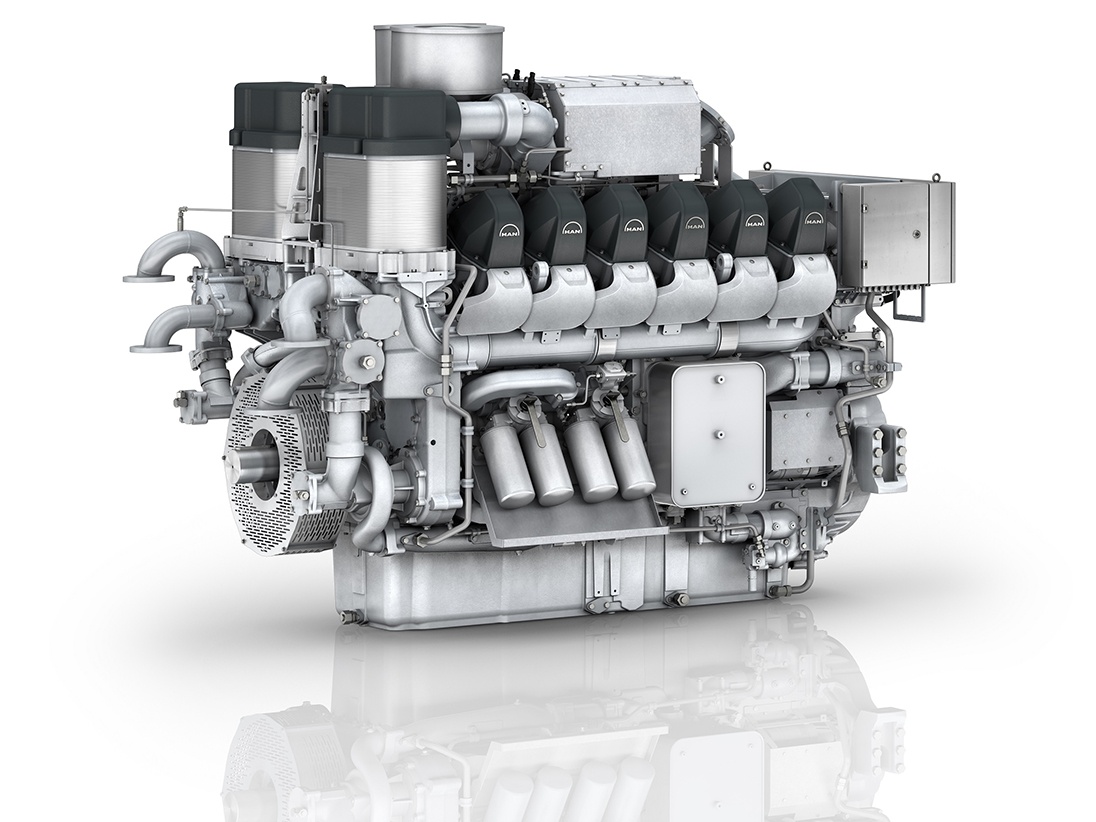

About the MAN 175D engine

MAN Energy Solutions has developed the MAN 175D engine range to supplement and complete its product portfolio in the maritime sector. Available in three variants of 12-, 16- and 20-cylinders, the engine is available with an output ranging from 1,500 to 4,400 kilowatts and is optimised for propelling ferries, offshore support ships, tugs and other working vessels. Other market areas, such as superyachts, planing yachts and naval marine applications are also served by additional engine variants.

The 175D is also an extremely eco-friendly engine, having been designed from the outset for low fuel consumption, coupled with compliance to the latest exhaust-gas-emission standards and considering as well future-fuel requirements where it is already cleared for operation on biofuels, such as FAME and HVO.