MAN Engines: V8 yacht engines available with SCR catalyst for IMO Tier III

MAN Engines is expanding its current engine portfolio for yachts and sport fishing boats to include engines in the current IMO Tier III emissions standard. V8 engines from 735 to 956 kW are now additionally available with the exhaust gas aftertreatment system.

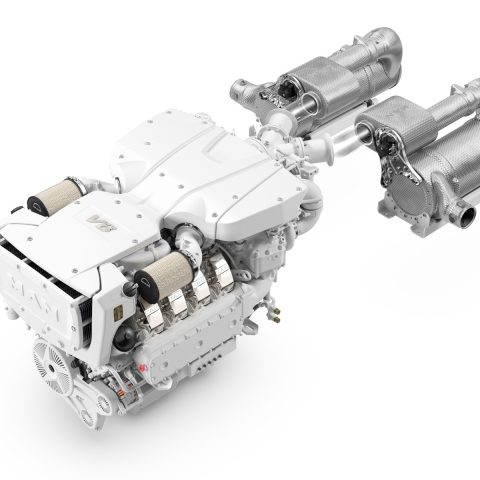

MAN Engines is expanding its current engine portfolio for yachts and sport fishing boats to include engines in the current IMO Tier III emissions standard. In addition to the V12 engines with SCR catalytic converter, V8 engines from 735 to 956 kW (1,000 to 1,300 hp) are now additionally available with the exhaust gas aftertreatment system. As a result, the engines meet the currently most stringent emission requirements of Tier III of the International Maritime Organization (IMO).

“By expanding the portfolio to include additional V8 engines in IMO Tier III, we are simplifying our customers’ business and expanding sales opportunities for additional boat series and to additional markets,” says Reiner Rößner, Head of Sales MAN Engines. With its six-, eight- and twelve-cylinder engines, MAN Engines’ complete portfolio for yacht engines covers a power range from 537 to 1,618 kW (730 to 2,200 hp). In the IMO Tier III emissions stage, these are specifically the engine types V8-1000 (735 kW), V8-1200 (882 kW), V8-1300 (956 kW), V12-1550 (1,140 kW), V12-1650 (1,213 kW), V12-1800 (1,324), V12-1900 (1,397 kW), V12-2000 (1,471 kW) and V12X-2200 (1,618 kW).

The first V8 yacht engines with common rail technology on the current MAN platform were first launched in 2009. In the meantime, many thousands of V8 and V12 engines on this platform have been established on the market and have been continuously further developed, increased in performance, and adapted to the latest emission specifications. As a result, MAN Engines now has an end-to-end engine portfolio for all global maritime emissions legislation.

Like the previous portfolio without an exhaust aftertreatment system, all marine engines with SCR catalytic converters are approved for use with regenerative diesel – also known as HVO (hydrogenated vegetable oil). Customers can use it to replace – or blend – conventional diesel fuel and use MAN engines with so-called green or renewable diesel. HVO cuts greenhouse gas emissions in exhaust gas by up to 90% compared with conventional diesel.

MAN Engines uses its modular exhaust gas aftertreatment system to comply with IMO Tier III emission limits. This system impresses with its exceptional flexibility and remarkable compactness and can thus meet the diverse requirements in the yacht sector. The modular exhaust gas aftertreatment system allows a demand-oriented and flexible system integration thanks to its variably positionable individual components. In addition to its compact dimensions and adaptability, this exhaust aftertreatment system also impresses with its low weight.

A positive side effect of using the modular exhaust gas aftertreatment system is the further significant improvement in fuel consumption of the already highly efficient marine engines by three to eight percent: “By using an SCR catalytic converter, our engines can be operated with higher raw emissions, which reduces fuel consumption. The pollutants that are not reduced internally in this case are reduced here by external exhaust gas aftertreatment,” says Werner Kübler, Head of Engineering MAN Engines. At the same time, complex exhaust gas recirculation and bulky and heavy components such as diesel particulate filters and oxidation catalysts can be dispensed with. This is crucial for reducing system complexity and realizing cost savings.

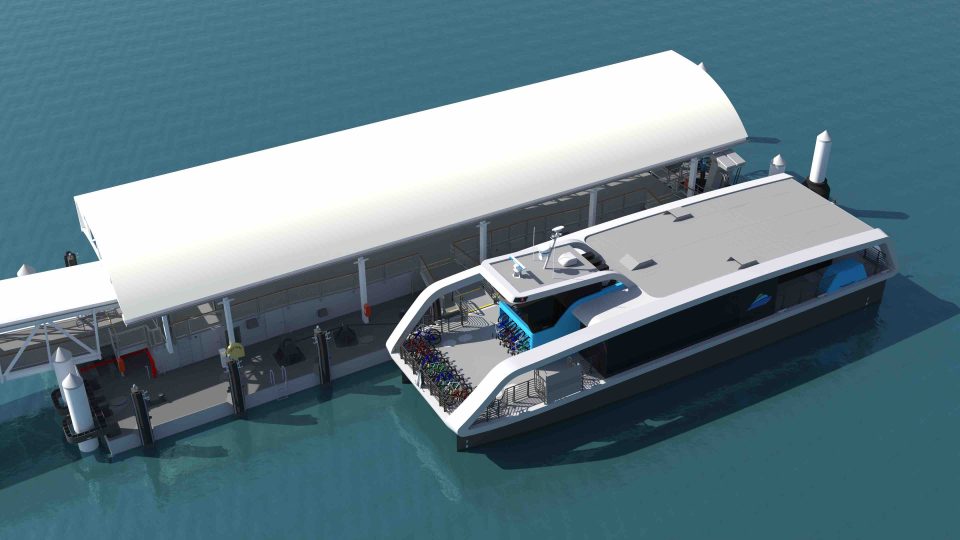

MAN Engines’ modular exhaust gas aftertreatment system was first presented at the International Workboat Show in New Orleans, LA, USA, at the end of 2017. By the end of 2019 – more than a year before IMO Tier III came into force – the first V12 engines with SCR systems from MAN Engines were already sailing on the Thames in London, meeting the new emissions standard. In the meantime, MAN Engines’ modular exhaust gas aftertreatment system has become firmly established in the marine sector and is characterized by long service life and high reliability. The basis for this solution to meet strict emission standards is based on the know-how of MAN Truck & Bus SE. As a leading European commercial vehicle manufacturer, the company has already successfully integrated SCR systems in series production in its trucks since 2006. In addition, MAN Engines benefits from experience in installation and integration from the area of engines for agricultural machinery as well as for industrial applications. Here, the technology has been successfully used with in-line and V engines since 2015.

MAN Engines will be showing an exhibit of its eight-cylinder V-engine with a modular exhaust gas aftertreatment system at the Cannes Yachting Festival. In addition, the issue of sustainability is an important concern for MAN Engines. In addition to the MAN V8-1300 with SCR catalytic converter, MAN Engines is therefore presenting solutions and bridging technologies that will help to operate yachts with the lowest local CO2 emissions in the future.