SAIM Marine introduces ExiLencer

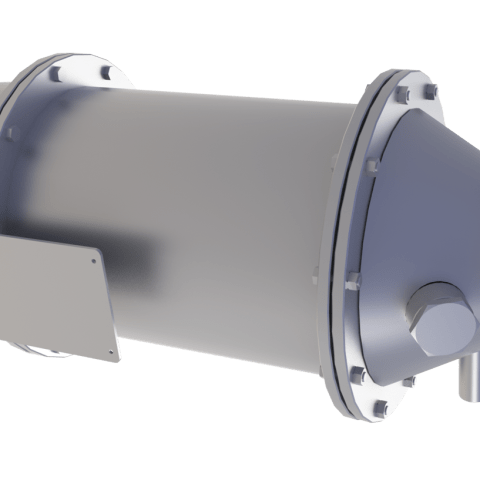

SAIM Marine introduces ExiLencer, an innovative solution by the Danish company Exilator, which manufactures exhaust gas purification systems with integrated silencers, a filter and a catalyst.

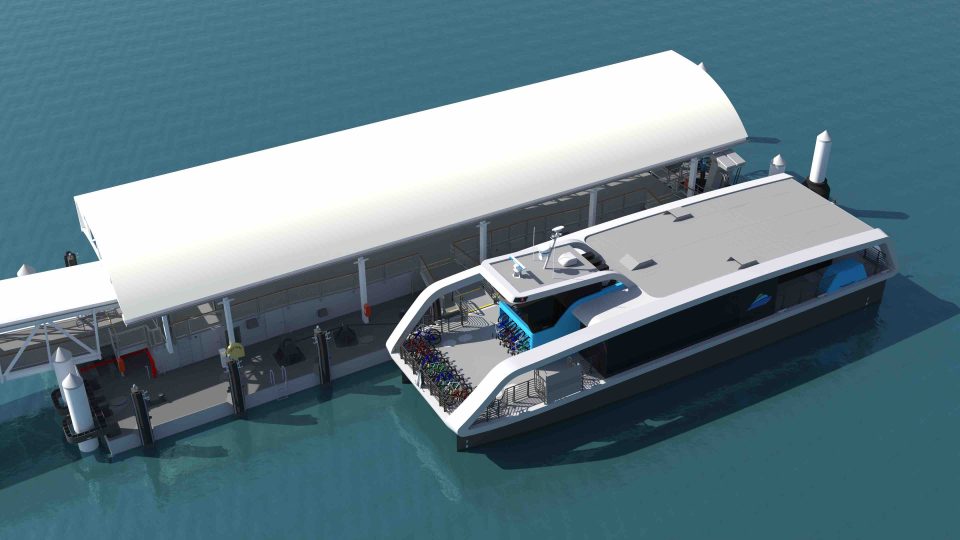

SAIM Marine is introducing Exilencer, a patented technology by the Danish Exilator, an innovative solution for reducing exhaust emissions, preserving the marine environment and increasing the comfort on board. The simple and effective passive exhaust gas filtration system consisting of an integrated silencer, a filter – with a ceramic or metallic coating – and a catalyst. A complete range for every boat to be used on marine engines or generators.

A simple and effective system, easy to install, operate and maintain, ExiLencer is a fully passive exhaust gas filtration system designed to reduce exhaust emissions, preserving the marine environment and increase the comfort on board yachts, mega-yachts and commercial vessels without complicated interventions in engine rooms.

It combines well proven technologies into one simple and effective system. Exilencer keeps regular and uniform back pressures at the engine exhaust, ensures efficient treatment of exhaust gas, reduces engine wear and pollutant emissions and is designed to be installed on gas exhaust line of generators or main propulsion engines and is sized according to engine power performance.

Two different models: ExiLencer 1.0 and ExiLencer 2.0.

ExiLencer 1.0 consists of an integrated silencer, a coated ceramic filter with a Nasa-developed coating – ExiBlock – and a NOx (nitrogen oxides) catalyst. The patented ExiBlock unit is coated with a special ceramic coating that works passively on the exhaust gas to reduce soot particules and unburn emissions. Soot particules are automatically filtered out at lower temperatures than conventional systems can do.

ExiLencer 1.0 is suitable for engines with exhaust gas backpressure in the range 1.5-6.0 kPa and temperature above 325° C. It removes 99% of soot particules, eliminates 99% of carbon monoxide, reduces noise emissions by 35dB and NOx content by up to 10 %. Filter blocks just need to be cleaned once a year or after 5.000 hours operation and can be reused up to 10-12 times.

Exilencer 2.0 features a metallic coating. It is suitable for engines with exhaust gas backpressure in the range 0.2-0.5 kPa and temperature just above 200° C. It removes 60% of soot particules, eliminates 90% of carbon monoxide and reduces noise emissions by 15dB and NOx content up to 10%. Filter blocks just need to be cleaned after 10.000 hours operation.

Both versions of Exilencer are available in 4 sizes.