Volvo Penta’s brand new self-docking system

Self-docking will be real by 2020 Volvo Penta presented its brand new solution for self-docking. This maneuver is known to be one of the most problematic of the nautical world. Self-docking, therefore, represents a long-awaited technological solution for modern-boating to open it to new potential customers. Narrow berths, changing wind and sea conditions, congestion of […]

Self-docking will be real by 2020

Volvo Penta presented its brand new solution for self-docking. This maneuver is known to be one of the most problematic of the nautical world. Self-docking, therefore, represents a long-awaited technological solution for modern-boating to open it to new potential customers. Narrow berths, changing wind and sea conditions, congestion of marinas may soon be no longer a problem.

The Swedish company plans to launch the self-docking system by 2020. This innovative technology is part of the current “Easy Boating” plan that Volvo Penta implemented to facilitate and extend access to boating. The presentation event included a live demonstration where a 68-foot yacht maneuvered and positioned itself between two of the Volvo Ocean Race 65 racing boats.

IPS and EVC

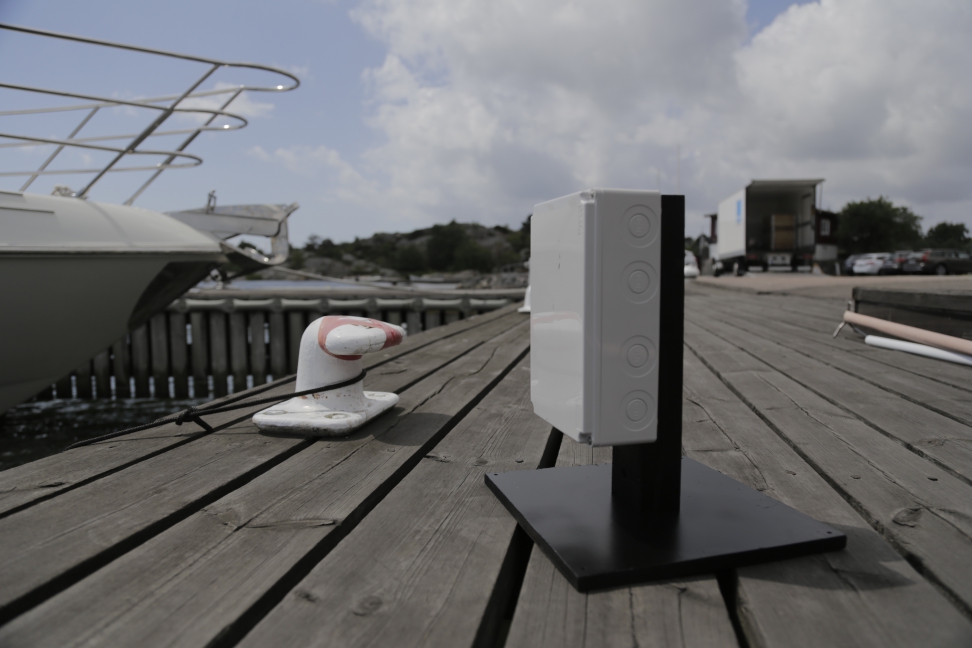

The joystick-controlled Inboard Performance System (IPS) is the central element of the automatic docking system. The integrated electronic control system of the boat (EVC) manages the connection. So, the EVC performs driving calculations in relation to the actual position of the boat and of the four sensors mounted on the berth. The sensor network, the computing power and a complete and integrated propulsion system complete the equipment. The system also works in reverse, guiding the boat out of the dock.

«Docking is one of the most challenging boat handling maneuvers. It can be embarrassed, expensive and precarious», says Björn Ingemanson, President of Volvo Penta. «Our IPS system has already taken great strides in making docking easier, and this new self-docking feature takes that process one important stage further. Its sensors and onboard computers react in milliseconds to changing wind and sea conditions. They are constantly making micro adjustments in power and steering angle of the IPS drive to keep the boat on its intended course into a safe berth. If Necessary, the docking process can be paused, and the system will hold the boat stationary in the water. Even in changing sea conditions it can make the sea appear to stand still».

How it works

The automatic docking consists of three phases. Approaching its berth, the boat system recognizes that it has entered a “catch zone” and sends a signal to the captain. Then, when the captain activates the auto-docking function, thanks to the GPS the boat moves automatically to a “docking ready” position. The captain then starts the final phase, and the system uses a combination of GPS and sensors (both onboard and on berth) to let the boat move autonomously to a safe place.

«We have long had the ambition to make docking as easy as possible», said Johan Inden, Chief Technology Officer at Volvo Penta. «The first step towards was in 2006, with the launch of our joystick docking technology. This was followed by the introduction of the Dynamic Positioning System, which automatically maintains a boat’s heading and position, even during strong currents or windy conditions – ideal when preparing for docking. Now, we are taking the next important step by enabling the boat to dock itself. With our easy docking concept, we aim to attract more people to enjoy the boating experience».

Application and market

The first commercial target consists of all those potential customers who can install the system on their own private dock. Looking ahead, Volvo Penta believes that the technology will be of considerable interest to commercial and tourist ports. Moreover, the self-docking system could couple with the Volvo Penta Easy Connect app to create an even smarter environment.

This could allow users to check if the nearest marina has the appropriate automatic docking technology. Indeed, one could use the technological combination to secure a parking space. An interesting possibility of the system is that it will be available not only for the latest boats equipped with IPS. In fact, it can also work in retrofit mode, and this could extend the interest to thousands of boat owners.

The Volvo Penta docking system is not designed to be fully autonomous. Although there are sensors that warn with anti-collision alarms, the captain must remain at the helm during the docking process. Following, the video demo made by Volvo Penta that shows the technology at work.