Agritechnica, engines and so on

Agritechnica is the place to be for combustion engines, gearboxes and chassis to hydraulics, electrification and assistance systems

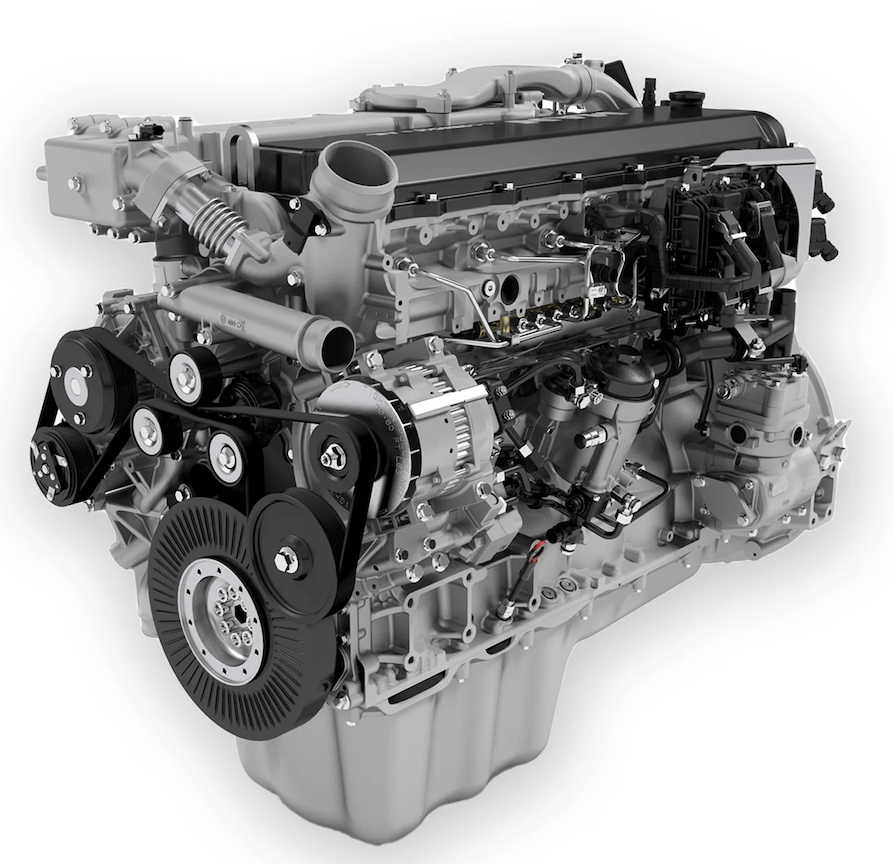

Agritechnica 2025 will also be the right place to shed light on the state-of-the-art of internal combustion engines technology. In the words of the DLG. According to DLG, Stage 5 emissions standards for non-road vehicles have been in force for several years, and the further development of tractors is currently no longer driven as strongly by legislation on nitrous oxides and particulates as it was in the past.

Engines and CO2 in the spotlight at Agritechnica

Today, the focus is more on reducing CO2 emissions and consequently on the use of alternative fuels. Many manufacturers have approved the drive units of their current model series for operation with RME (rapeseed methyl ester) and HVO.

In the background, work is being done on the usability of other alternative fuels, such as ethanol or hydrogen. Like RME and HVO, ethanol is a liquid fuel, but its volumetric energy density of around 21 MJ/l is significantly lower than that of diesel (around 36 MJ/l). Ethanol can be used in ICE that operate according to the Otto cycle with external ignition.

This alcohol fuel is likely to be of particular interest to countries that can produce it themselves from sugar cane or maize, such as Brazil. Case IH is introducing a Puma 240 tractor with a modified 6-cylinder engine for markets like these. The FPT Industrial N67 unit is based on the NG (natural gas/methane) version, but has been modified in various areas to run on ethanol.

And the engine peripherals

In the case of classic Diesel engines, manufacturers are increasingly focusing their attention on the “peripherals”. Several new tractor series equipped with automatic reversing fans will be presented at Agritechnica 2025. There are also new developments in devices that can increase the drag torque of engines when driving downhill in order to protect the service brakes (wear-free continuous brakes).

In addition to the familiar options of “baffle plate” and “constriction of the flow cross-section for VTG loaders”, CNH also uses a decompression valve in its new large tractors developed in Europe. This technology, which uses an additional valve per cylinder, originates from the truck industry and allows the compression pressure to be released at the end of the second stroke. As a result, the piston is pushed down less forcefully in the third stroke, which leads to significantly higher engine drag torques.

Fendt also utilises the VTG loader option in its new 700 (Gen7.1) and 800 (Gen5) series and in addition relies on a so-called “hydraulic auxiliary brake”. The working hydraulic pump pumps oil against resistance, thereby converting kinetic energy into heat energy. This type of continuous brake has also been offered by SDF for several years.

Two years ago, Fendt presented an automatic system for extracting dust from the engine air filter. This is now being expanded to include the cabin air filter and is available for the new 800 Gen5 and 1000 Gen4 series. The revised 1000 series continues to use MAN’s familiar D26 6-cylinder engine (12.4 litre displacement), but all models now feature DynamicPerformance (DP) with increased power output of up to 30 hp.

Consequently, the top model 1052 achieves a maximum output of 550 hp. Because not all attachments are designed for such high power outputs, Fendt offers the new “AdaptivePower” function. This means that, on larger models, the power curves of smaller models can also be selected via the FendtONE terminal. That protects implements from overload and also enables lower fuel consumption (e.g. through more moderate acceleration during transport work).