Carraro conceived “THE solution”

Carraro has introduced "THE," a transmission available in both hydrostatic and electric versions, to the construction market. And the market response is encouraging

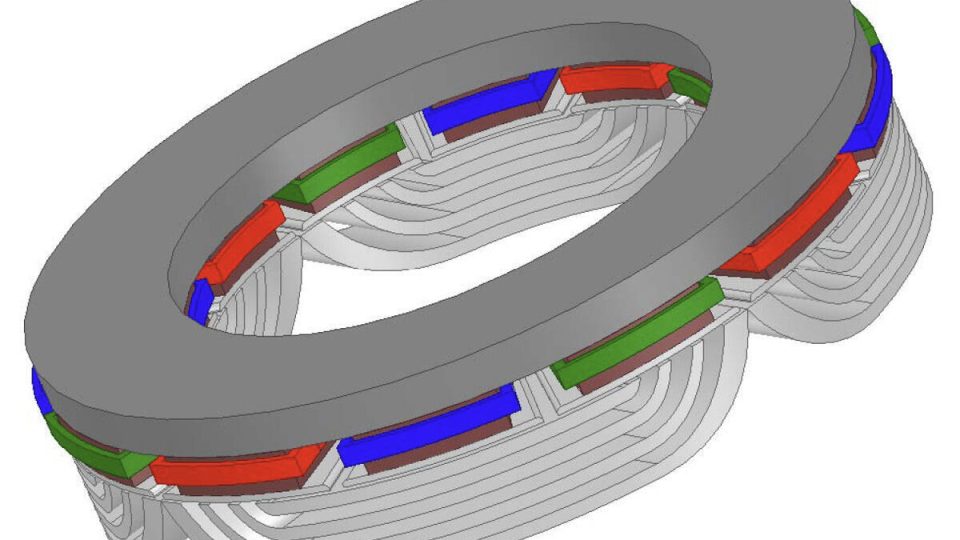

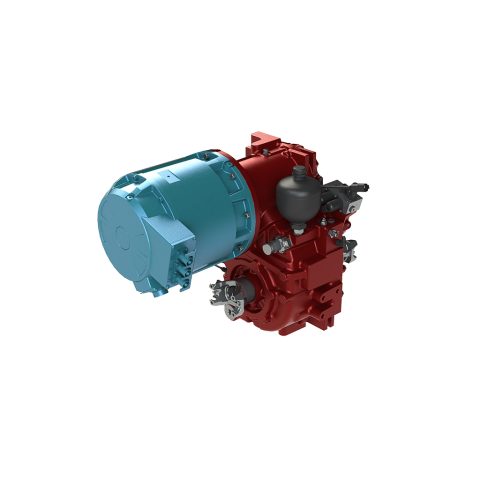

The “THE” article effectively indicates the perfect embodiment of a concept. Here we’re talking about “THE solution” aka, the transmission. This is not a case of narcissism, Carraro conceived “THE solution” as the agnostic synthesis of sustainability in its true meaning. It means the possibility to set up a vehicle in a hydrostatic or in an electric version without making changes to the driveline layout. The THE transmissions will be available with a synchronized two-speed gearbox and powershift options. On demand, they can be configured to include a parking brake and a 4WD disconnect system. Fulvio Lo Conte is the Sales & Marketing – Business Development Director at Carraro. We asked him to give us more details on the THE series.

The Story of “THE Transmission,” by Carraro

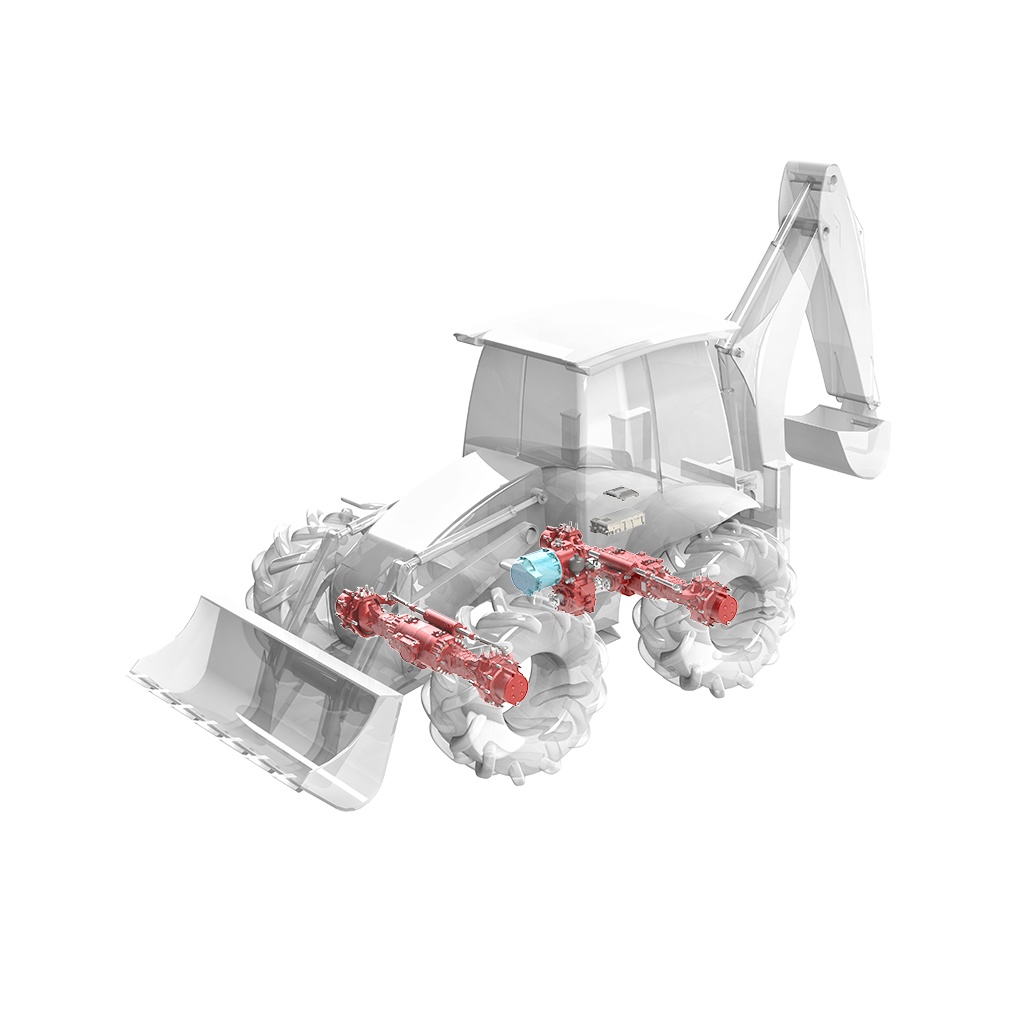

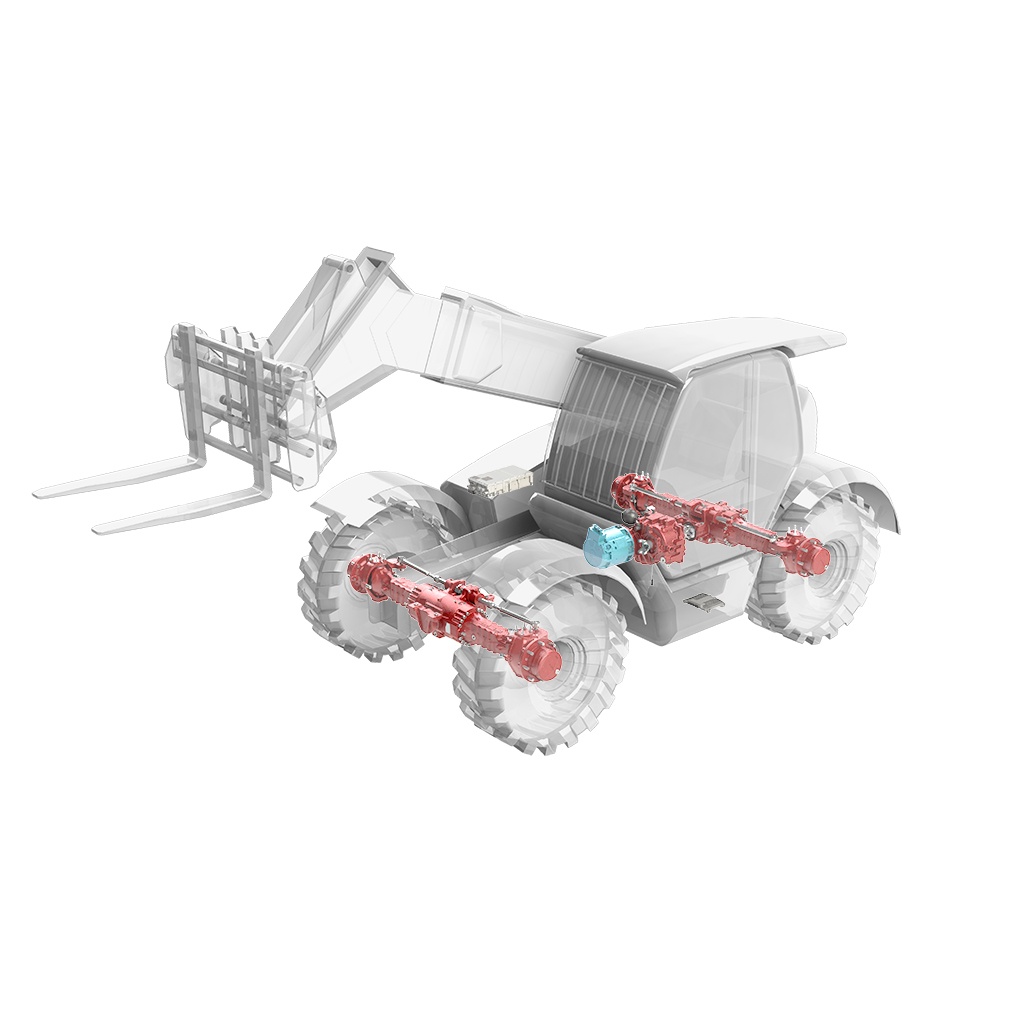

His answer opens with a familiar preamble: “We are solution providers” What does that mean to them specifically? “We can offer suitable products to fit any type of machinery, suggesting the most appropriate technology for the individual application, typically telescopic handlers, backhoe loaders, compact and small wheel loaders, and wheeled excavators. The new transmission has to cover these applications, up to 120 kW. The wheelbases were conceived to fit the optimized diameters of electric machinery. At this stage of technological transition, even though reaffirming the validity of conventional hydrokinetic solutions, it is vital for Carraro to expand their offer of the hydrostatic solutions that are increasingly dominant, to finally implement the electric solution more easily”. In the following lines, Lo Conte provides the perfect caption to his definition of the company as system provider. “Our simulation capabilities are such that we can indicate what technological solution is the most suitable for each application. Our products, from the conventional ones to the most innovative, are what we are putting in” says Lo Conte, going back to simulation. “We have the capability to simulate the performance cycle of the entire vehicle, to compare productivity, consumption levels, comfort, but we are also working on a Digital Twin model that allows us to obtain a more realistic simulation of the behaviour of the machine as driven by the operator. We do not want to push this or that solution, but rather meet the needs of our customers based on competence and experience. With THE, we start from a hydrostatic, electronically controlled architecture to migrate to an electric one without impacting on the mechanical parts that transfer motion.”

Details of the cooperation with Danfoss

“Carraro in partnership with Danfoss can simplify the architecture of electronic control units to the point we have one single control unit for the whole driveline or powertrain in the case of electric versions”. And it was the THE transmission that prompted such technological partnership between Danfoss and Carraro. Integrating all the driveline management functions into one control unit brings about a series of benefits, including optimized shifting with PowerShift (HST) or SynchroShift (electric) and the vehicle software’s full smart control capabilities. So smart that, Lo Conte explains, “The integrated development of controls leads to optimized performance aiming for the most efficient working conditions, reduces the number of control units, but also means less time needed for system development and validation- hence lower costs- compared to starting from a clean slate. Normally, we work on compact wheel loaders up to 9.5 tons with hydrostatic transmissions, both single speed and two-speed. Our THE products were instead developed with bigger sizes in mind, up to maximum 14 tons. The transmission is basically interchangeable, and thanks to our simulations, we can offer the synchronized, shift on fly version for the electric version and the powershift for the hydrostatic one”.

You will soon find the full article available online on page 40 of the digital version of POWERTRAIN International magazine.