Components at Agritechnica

Following our previous discussion on engines and peripherals, we now share DLG's latest impressions regarding hydraulics, electrification, and gearboxes

Agritechnica also means Systems & Components, which naturally includes engines and peripherals, topics we have already covered in this article. Today, we will share some insights provided by the DLG concerning gearboxes, hydraulics, and electrification.

Let’s start from hydraulics components at Agritechnica

At Agritechnica concerning the components in large tractors, the trend towards two completely separate hydraulic circuits, each with a variable displacement pump, continues. One circuit can be used, for example, to supply continuous consumers such as blower drives for air seeders, while the other circuit can be used to supply “sporadic” consumers such as chassis cylinders or track markers. To ensure that sufficient hydraulic oil is available, tractor manufacturers are increasingly installing separate tanks, which also reduces the amount of dirt entering the gear oil.

Load-sensing (LS) hydraulic systems have been standard equipment on premium tractors for years. The ‘Power Beyond’ extension with P, R and LS connections (pump/pressure line, return/tank, load sensing) is also available for supplying implements with their own valve blocks. As a result, fewer hydraulic lines need to be connected and the tractor’s own directional control valves can be bypassed, leading to improvements in efficiency. LS systems are regulated according to a constant difference (around 25 bar) between the pump pressure and the highest load pressure applied to the directional control valves. The longer LS lines in “Power Beyond” affect this control variable, which can have a negative impact on the hydraulic functions of attachments (e.g. delayed response or uneven running).

Premium tractors are likely to be increasingly equipped with electronically controlled load sensing systems (e-LS) in the future. At Fendt, these are already standard equipment on the 500 Gen4, 600, 700 Gen7.1 and 800 Gen5 series. It is also expected that manufacturers of implements will increasingly switch to e-LS, and ROPA already offers its first machine of this type with the “Keiler II RK22” potato harvester. However, the use of tractors and attachments with e-LS still requires a hydraulic LS connection, and the advantages of purely electronic communication cannot be fully exploited. Fendt and ROPA therefore jointly developed “e-LS connect”, which allows load pressure signals to be exchanged between the tractor and implement purely digitally via ISOBUS, eliminating the need for an LS cable.

Moving to electrification

Battery-powered series tractors in the lower power range are now available on the market, but the big breakthrough is still likely to be some time in coming. A major obstacle is the high cost of batteries, which almost doubles the selling price compared to comparable diesel models. It is to be expected that battery-electric tractors will have lower variable costs, but there is currently no empirical data to suggest whether the higher investment costs can be offset in a TCO analysis.

Chinese manufacturer ZSHX Advanced Tractors aims to shake up the European market with the XEEVO E904i. It was designed from the ground up as a battery-powered tractor and is expected to cost only around € 100,000. The drive concept features two electric motors arranged side by side. One is used for the drive, the other for driving the rear PTO and working hydraulic pumps. The continuous/peak power outputs are 66/90 kW respectively. The LFP battery with a capacity of 105 kWh is installed in the front half-frame of the tractor. v It is designed for charging/discharging capacities of 115 kW, which is to enable fast charging with DC current within one hour.

John Deere will present a battery-powered tractor with 96 kW (130 hp) at Agritechnica. This is based on a model platform that was also designed from the ground up for electric drive technology and autonomous driving. The latter is based on camera/LiDAR systems and purely electric “by-wire” control of steering, brakes, etc. The E-Power models can be equipped with up to five NCM battery packs of 39 kWh each, resulting in a gross total capacity of 195 kWh. The voltage level is around 800 V, which corresponds to that of luxury cars and lorries. The e-axle is completely new and includes one electric motor each for the drive and the rear PTO (continuous output of 96 kW/130 hp each). The drive system is single-stage, which means that no driving range switching with clutches is required.

Another electric motor is provided to drive the working hydraulic pump, which in an initial phase is still designed as a variable displacement pump. In addition to these three electric motors for the working drives, there are four more for on-demand driving of “peripheral components”: cooling fan, heating/ventilation/air conditioning, gearbox lubricating oil pump and battery thermal management. In addition to the standard version, the E-Power series will also be available in “Narrow”, “Low Profile” and “High Crop” versions. This diversity and the entry of major manufacturer John Deere, which has been reporting high sales figures in these segments in its home market of the USA for years, could finally give battery electric tractors a boost.

The start-up companies ONOX and TADUS also continue to be active in the field of battery-powered tractors. The former relies on a tractor concept with three electric motors: one motor with 50 kW for the drive and two with 35 kW continuous power each for the front and rear PTO. In addition to the integrated 20 kWh battery, 30 kWh replacement batteries can be carried on the vehicle: in the front or rear three-point hitch or on the side between the axles. At 48 V, the voltage level is rather low for this performance class, but is below the high-voltage limit of 60 V applicable to electric vehicles.

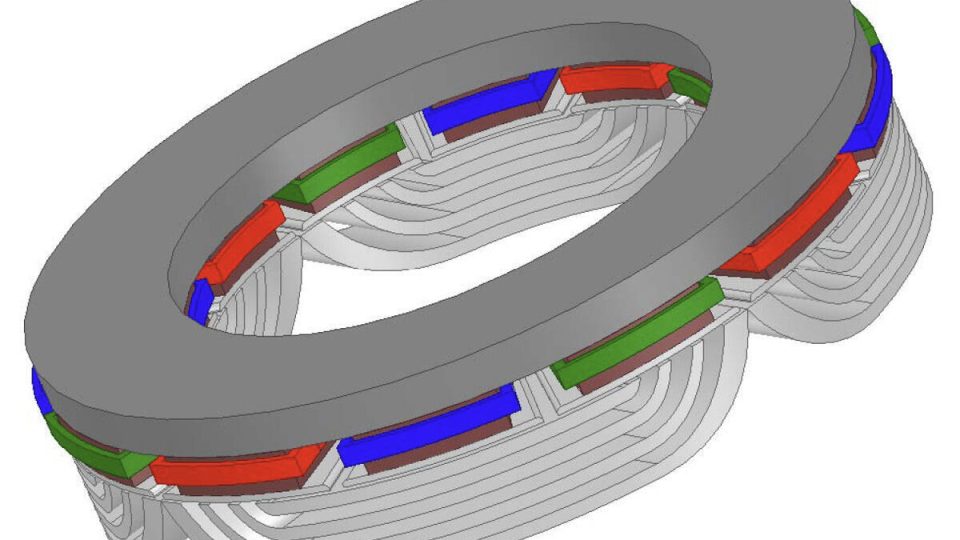

Tractor drive trains with high-power electronics are also being developed by manufacturers in Asia. TAFE from India submitted the study “EVX 75 Diesel Electric Hybrid Tractor” for the “Agritechnica Innovation Award”. The performance values of a classic tractor with 75 kW (100 hp) are to be achieved with a 55 kW (75 hp) diesel engine, two electric motors and a 25 kWh EVX75 battery. Chinese manufacturer Zoomlion, on the other hand, is attempting to position itself in the upper performance classes and is introducing an electrically driven gearbox-rear axle unit for tractors up to 400 hp. This comprises two coaxially arranged electric motors, which can be used separately or together for the drive system and rear PTO.

Finally to gearboxes

With the introduction of the new 500 Fendt (Gen4) series, Fendt is once again extending the VarioDrive concept with permanent all-wheel drive up to 25 km/h and now offers this across the board in the 500, 600, 700, 800, 900 and 1000 series. CNH developed its own stepless gearboxes with hydrostatic-mechanical power split. The previous version with 2/1 driving ranges (forward/reverse) has been expanded to include a third forward driving range (3/1) for installation in the new T7 SWB models with a short wheelbase. In addition, the larger CVT box with 4/2 driving ranges (F/R) has been adapted to the higher performance of the new large tractors. JCB is switching to stepless gearboxes from ZF for its new Fastrac 6000 series and is also changing its engine supplier to FPT (both components were previously supplied by AGCO).

AEBI Schmidt will be the first manufacturer to install the ‘Line Traction Version 3’ (LT3) drive concept. It was developed in collaboration with Müller in Bonndorf in a series-production vehicle, the AEBI TERRATRAC slope implement carrier. With LT3, not only can the longitudinal differential (speed compensation between the two drive axles) commonly found in such vehicles be dispensed with, but also the transverse differentials (speed compensation between the wheels of an axle). The drive shafts of all four wheels therefore always rotate at the same speed. In the downstream planetary final drives, the power flow runs – as usual – from the sun gear via the planetary carrier to the wheel hub. However, unlike conventional final drives, the ring gear in the LT3 drive is not permanently connected to the axle housing, but is instead supported hydrostatically by an external cam disk and radial pistons. When the TERRATRAC drives through a curve, the proportional valves integrated into the hydrostatic circuits (one per wheel) can be opened in a targeted manner, resulting in controlled counter-rotation of the hollow wheels. This in turn results in a reduction in the planetary carrier speed and therefore the wheel speed. The wheel furthest from the curve always plays the role of the “master”, which means that the ring gear is completely supported here. For the other wheels (“slaves”), which travel shorter distances in curves, the proportional valves are opened until the respective target speeds are set depending on the steering angle, speed and vehicle geometry (wheelbase and track). The practical advantage is that each wheel is driven at the correct speed, even when cornering. This improves traction, reduces damage to the sod and increases safety when turning on slopes, where conventional drive concepts with differentials would require the locks to be released.