IAA: Cummins debuting electrified Meritor powertrains for the first time since acquisition

For the first time since finalizing the acquisition of Meritor last month, Cummins will showcase Meritor’s 17Xe ePowertrain assembled with a Cummins battery system during the IAA Transportation tradeshow in Hannover, Germany.

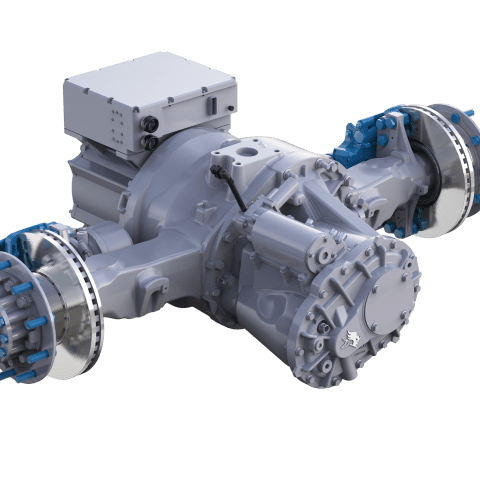

For the first time since finalizing the acquisition of Meritor last month, Cummins will showcase Meritor’s 17Xe ePowertrain assembled with a Cummins battery system during the IAA Transportation tradeshow in Hannover, Germany. The 17Xe is designed for heavy-duty trucks in the 4×2 and 6×2 segment, with capacity to support 44 tons of gross combined weight, or more in some applications. The assembly also features a lithium iron phosphate (LFP) battery pack, a new arrival to Cummins’ battery line-up.

“We are committed to bringing Cummins and Meritor electrified powertrain solutions to market as quickly as possible. We are moving faster together and are eager to talk about solutions at IAA that will move us all closer to decarbonizing our industry,” said Amy Davis, Vice President and President of New Power at Cummins. “Cummins and Meritor bring together the industry’s best, most economically viable decarbonized powertrain solutions that are better for people and our planet.”

Meritor brings more than 100 years of experience in drivetrain, mobility, braking, aftermarket and electric powertrain solutions to Cummins. The integration of Meritor’s people, products and capabilities in axle and brake technology will position Cummins as a leading provider of integrated powertrain solutions across internal combustion and electric power applications.

With 100% zero-emissions ePowertrains already in production, the combined strength of Cummins and Meritor delivers advanced, decarbonized transport solutions for the commercial vehicle market.

Cummins is integrating Meritor’s ePowertrain with battery and fuel cell electric drivetrains to meet the growing demand for decarbonized solutions. Cummins’ market-leading suite of clean drivetrain options offers performance and packaging advantages to suit diverse applications across the globe, with significant benefits to heavy- and medium-duty truck and bus work cycles and ranges.

In addition to the ePowertrain, Meritor’s Power Control and Accessory System (PCAS) will be on the show floor. The PCAS is considered the “brains” of the electric powertrain and controls speed, acceleration, braking and thermal management. Through innovative software controls it can be configured to maximize performance and overall system efficiency. Its integrated system design also reduces packaging size and integration complexity.