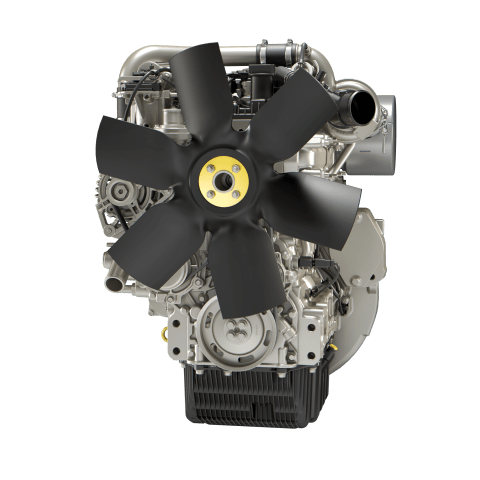

Perkins: over 100,000 2.8 and 3.6 litre engines installed

The popular range of 2.8 and 3.6 litre Perkins engines, which went into production in May 2019, have now surpassed 100,000 units installed in everything from excavators to tractors and dumpers to pumping equipment.

The popular range of 2.8 and 3.6 litre Perkins engines, which went into production in May 2019, have now surpassed 100,000 units installed in everything from excavators to tractors and dumpers to pumping equipment.

Engineered to integrate perfectly into more than 80 different machine models, the 2.8 and 3.6 litre Perkins engines continue to deliver the performance, value and reliability customers expect to help them access new opportunities and support their business growth.

“We’ve always had high expectations for the 2.8 and 3.6 litre engines and they’ve met our expectations and more,” said Matt Coleman, product manager for the range. “Our global customer base quickly appreciated how the 2.8 and 3.6 litre models could add real value to the productivity and performance of their machines. Now, over 100,000 of these versatile engines, which meet global emissions standards including EU Stage V and US EPA Tier 4 Final and more recently China Nonroad Stage IV, can be found powering applications in the agricultural, industrial, material handling and construction sectors.”

Compact, powerful and quiet

The 2.8 and 3.6 litre engines have proved to be a “game-changer” for many customers, thanks to their high power density and torque, giving OEMs the opportunity to move to smaller, more compact engines. Manufactured in both Peterborough, UK and Wuxi, China, the 2.8 and 3.6 litre engines provide customers with the great fuel consumption, fast response and electronic integration they need to differentiate their machines, which is achieved through an increase in power density of up to 22 percent when downsizing.

While the compact nature of the engine and aftertreatment system package enables the 2.8 and 3.6 litre models to fit in a wide variety of machines. Up to an 8 percent improvement in fuel economy during machine use, with the 3.6 litre delivering powers up to 100 kW (134 hp) with up to 550 Nm of torque, has also been well received.

Since 2019, the range has been expanded, with production on the China Nonroad Stage IV offering starting in January 2023 and the introduction of the 2.8 and 3.6 litre industrial open power units for the agricultural and industrial sectors in November 2022.

“We are always searching for better ways of helping customers achieve their goals, to enable their continued success,” said Jaz Gill, Vice President Global Sales, Marketing, Service and Parts. “The addition of the 2.8 and 3.6 litre engines to our range of sustainable power solutions truly embodied that sentiment. So today, whether our engines are powering a dumper, heavy articulated tandem roller, pumping equipment, tractor, skid steer loader, excavator, telehandler or backhoe loader; by working together with our customers, we have created better power solutions for all.”