Volvo and Covid-19. Swedish pioneers of precautionary measures

Volvo and Covid-19. The Swedish mood Volvo and Covid-19. The Swedish group alerted its employees to the outbreak of the virus and was not unprepared. The first objective is health protection. We asked them for their impressions of this difficult time. VOLVO GOES AUTONOMOUS! The Volvo Group has been a pioneer in the implementation of […]

Volvo and Covid-19. The Swedish mood

Volvo and Covid-19. The Swedish group alerted its employees to the outbreak of the virus and was not unprepared. The first objective is health protection. We asked them for their impressions of this difficult time.

The Volvo Group has been a pioneer in the implementation of safety measures to prevent the spread of Covid-19. What thoughts led to this decision? Was the need of getting protective measures an obstacle to guarantee the manufacturing process? And what’s the situation at the Skövde foundry (a ‘model factory’ in this specific kind of activity)?

The world around us is changing at an extremely fast pace. At this stage, it is virtually impossible to maintain the normal operations of the Volvo Group and a gradual closure of the production system has taken place across Europe but also in other markets. This includes the production facility in Skövde. The aim is to start up production again when we have stability in the markets where we have facilities and in the supply chain.

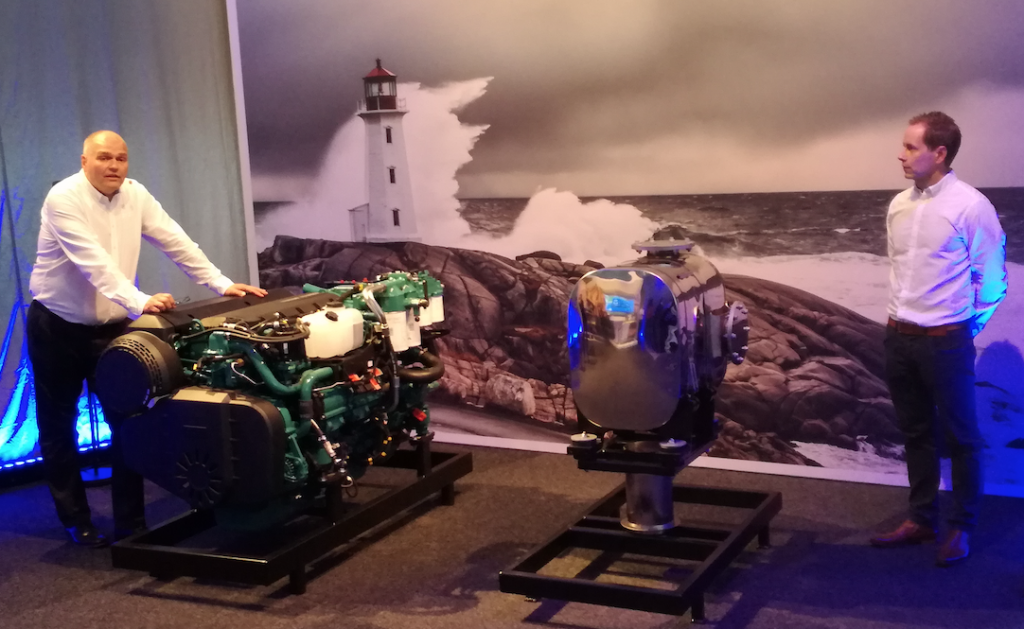

These measures have an impact especially on the shipbuilding industry, which is entering its busiest time of the year. Do you have enough engines and IPS in stock to process orders? And how are you managing the manufacturing and shipping schedules? Do you have production facilities around the world that have not been affected in the same way as those in Europe?

We are currently working to keep our customers informed on an ongoing basis of the status. We are still processing orders, but the estimated delivery times are preliminary only.

Due to its health origin, the current crisis is certainly different from that of 2008. However, is there, in your opinion, any shared element? And can the experience that the majority of entrepreneurs and managers have lived through at that time help them face the current moment?

The Corona virus (Covid-19) epidemic is affecting us all – first and foremost from a health perspective. We are doing our utmost to safeguard the safety and well-being of employees, operations and customers. What we can understand from the past is that in any crisis, there is a need for strong leadership and engagement from the company, which we have within Volvo Penta.

Is Volvo’s official electrification program confirmed in 2021 or will it slip?

It is too early to talk about the impact to specific aspects of our business, like electrification. We are not speculating at this stage.

How do you imagine the world after the Covid-19, in terms of communication and trade events (fairs and so on)?

When we look ahead, we can imagine that there will be an increased focus on digital communication as a result of Covid-19. We can’t predict exactly how this will evolve, but we see already now that the world is shifting even more in this direction; there are many new approaches to connecting digitally that are already taking shape now, which are inspiring us.