Komatsu XF895-3 and AGCO Power 74HD

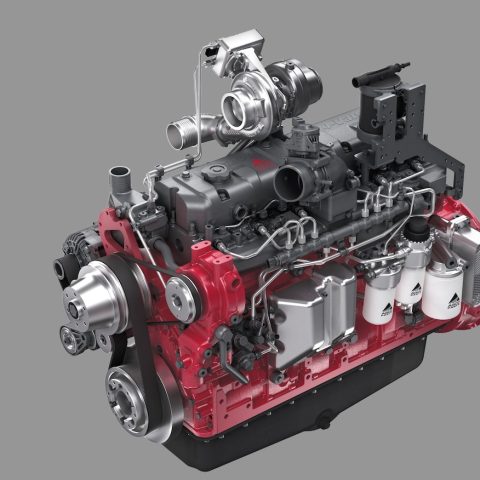

For its forwarders, Komatsu maintains a privileged partnership with AGCO Power. The XF895-3 is equipped with the 74HD engine, while the heavier 898 model features the CORE75. Despite having nearly identical displacements, they offer different technological features and performance curves

AGCO Power has a natural, ‘geographical’ affinity for forestry applications, as demonstrated by Komatsu’s interest. For the North American market, Komatsu has chosen the AGCO Power 74HD engine to power its XF895-3 forwarder.

The Komatsu Forwarder Features the AGCO Power 7.4L Diesel engine

The 6-cylinder engine is the predecessor of the CORE75, featuring a single cylinder displacement of 1.23 liters (Bore x Stroke 108×134 mm). The power and torque curves, peaking at 213 kW and 1,280 Nm respectively, intersect at approximately 1,700 rpm.

Following the launch of the XH951XC-1 8-wheel model last September, Komatsu has doubled down by unveiling the XF895-3 forwarder. This machine has been purpose-built with a smarter design and more durable components to ensure high performance and productivity in the most demanding forestry operations.

This model was specifically engineered by the Japanese manufacturer for final felling and large-scale extraction. To tackle these heavy-duty tasks, the Komatsu XF895-3 features an updated crane, a reinforced chassis, and a redesigned load space aimed at streamlining the transport of larger loads. Furthermore, its 8-wheel drive system delivers exceptional traction, maneuverability, and stability, particularly on steep, soft, or uneven terrain.

In the forests, under any operating conditions

Among the updates introduced by Komatsu on this model, we find a new optional 205F crane featuring improved lifting geometry and an optional reach of up to 32.8 feet (10 meters), alongside an optional G85H grapple with a tip-to-tip area of 4.3 square feet (0.40 m²) for enhanced material control.

The bunk is telescopic, featuring heavy-duty bunks with a widening function and optional height-adjustable stakes. Both the chassis and the articulated joints have been reinforced, engineered to withstand the machine’s increased load capacity. The package is completed by a new electronically controlled hydraulic pump, which improves responsiveness and fuel efficiency, and a new hydraulic tank design with a single filter to simplify maintenance operations.

“The improvements made to the XF895-3 make it even better suited for large log forwarding, final felling, and site preparation,” said Rob Warden, Senior Product Manager, Forestry. “It features a sturdier frame for increased durability, along with a more powerful new optional crane. The load space offers extensive adjustability for your operations, such as telescopic width and height adjustments and a fully adaptable gate.”

Inside the cab, operators enjoy automotive-grade quality with refined controls and features designed to ensure comfort and precision throughout the workday. The XF895-3 forwarder was designed to operate in tandem with the XH951XC-1, one of the largest harvesters on the market. Together, the XH951XC-1 and the XF895-3 reflect Komatsu’s ongoing innovation in the forestry sector, allowing operators to achieve more with greater comfort, control, and safety.