Alleima releases carbon footprint data to Epiroc Drilling Tools

Alleima will be one of the first companies to implement Life Cycle Assessment (LCA) for rock drill steel products for the mining industry. As a start, Alleima will release carbon footprint data for its rock drill steel products to its customer Epiroc Drilling Tools.

Alleima will be one of the first companies to implement Life Cycle Assessment (LCA) for rock drill steel products for the mining industry. As a start, Alleima will release carbon footprint data for its rock drill steel products to its customer Epiroc Drilling Tools.

Climate change is an existential threat to the world. With rising carbon dioxide emissions at the heart of this threat, European Union has committed to creating a climate-neutral society by 2050, and reducing greenhouse gas emissions by 55% by 2030, compared to 1990 levels. One of the keyways in which industries can support these climate goals is by reducing the levels of carbon they emit. Therefore, Alleima has decided to implement Life Cycle Assessment (LCA) and will be one of the first companies to provide product-specific carbon footprint for rock drill steel products for the mining industry. Each product will have a third-party verified carbon footprint.

“This is an important step for us as it gives us the opportunity to show that the carbon footprint is important. We believe that the LCA data from Alleima will give Epiroc Drilling Tools an advantage in the industry and having a lower carbon footprint will be a competitive advantage for the future. By using greener steel, we can make a joint statement, contributing to a greener future together”, says Michael Jansson, General Manager at Epiroc Drilling Tools.

“We are pleased to tell that we can now support Epiroc Drilling Tools with a product-specific carbon footprint. By collaborating with our customers and implementing sustainable solutions, we can all contribute to making greener choices for the industry. Sustainability is of crucial importance for the society around us as well as for our customers and LCA will be important for businesses in the future. The next step for Alleima is to expand this approach across the entire production chain, verifying downstream products in the production flow”, says Mattias Eriksson, Global Product Manager for Rock Drill Steel products at Alleima.

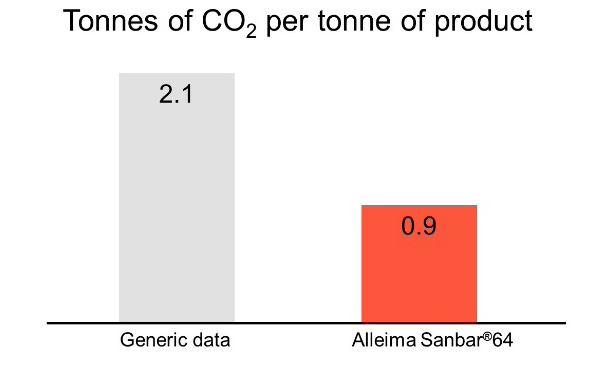

Rock drill steel (RDS) products from Alleima have a low carbon footprint. Alleima has significantly reduced carbon emissions through efficient processes, the use of fossil-free electricity, and dedicated investments such as switching to fossil-free fuels for heat treatment. Alleima products have a high scrap content, reducing the need for primary resources.

Alleima has been reusing steel scrap in production for over 100 years. To use electric arc furnace is today given and there is a strong focus on reducing the carbon footprint through the whole organization. In December 2022, Alleima decided to commit to set science-based net-zero targets, consistent with the Paris Agreement. Epiroc Drilling Tools has also committed to the science-based targets initiative (SBTi).