Cummins at Agritechnica: go with hydrogen!

In Hannover Cummins confirmed its commitment to the Destination Zero strategy, especially in the part dedicated to hydrogen, which is now a protagonist not only in agnostic engines, but also in production and supply phases. For agricultural OEMs, the direction is increasingly towards the “tailor-made” solution. We talked about it with Steve Nendick, Marketing Communication Director, and Philip Dawson, General Manager Agriculture Business

At Agritechnica Cummins confirmed its commitment to the hydrogen economy as part of its Destination Zero strategy, already made clear by recent investments and acquisitions. There are three fronts on which it intends to focus: the production of green hydrogen, the management and transport of hydrogen and the application of hydrogen in engines and fuel cells.

As for the first aspect, green hydrogen production, Cummins is opening new electrolyzer plants in La Mancha, Spain, and Minnesota, as well as expanding production in Oevel, Belgium, and Mississauga, Canada. With over 600 electrolyzers distributed globally in 100 countries, Cummins is investing heavily in this technology. For storage, the launch of the joint venture with Nproxx, a world leader in high pressure hydrogen storage for both stationary and mobile applications, was of fundamental importance.

Regarding agricultural applications, which are the protagonists of Agritechnica, Philip Dawson, General Manager, Global AG Business, states: “We are building experience in the electrification, through our Accelera by Cummins division. I see that for tractors which operate near the farm, where it is easy to implement an infrastructure, they will adopt electric before open field tractors. Large open field machines have to carry out heavier work and require higher performance and longer working hours. So I think that battery technology will be limited to smaller tractors, while the challenge becomes more difficult with larger tractors, where the battery capacity may not be sufficient for their working needs. For our diesel engines, they are already all compatible with HVO biofuel and offer a level of environmental benefit. There are other biofuels that could be particularly interesting for the agricultural market, for example ethanol in South America, which could fuel a circular economy for farmers. For our new hydrogen combustion engine, it can provide similar performance characteristics to our diesel engines, with challenges related to hydrogen storage and production to be oversome.” Themes on which Cummins focused in this edition of Agritechnica.

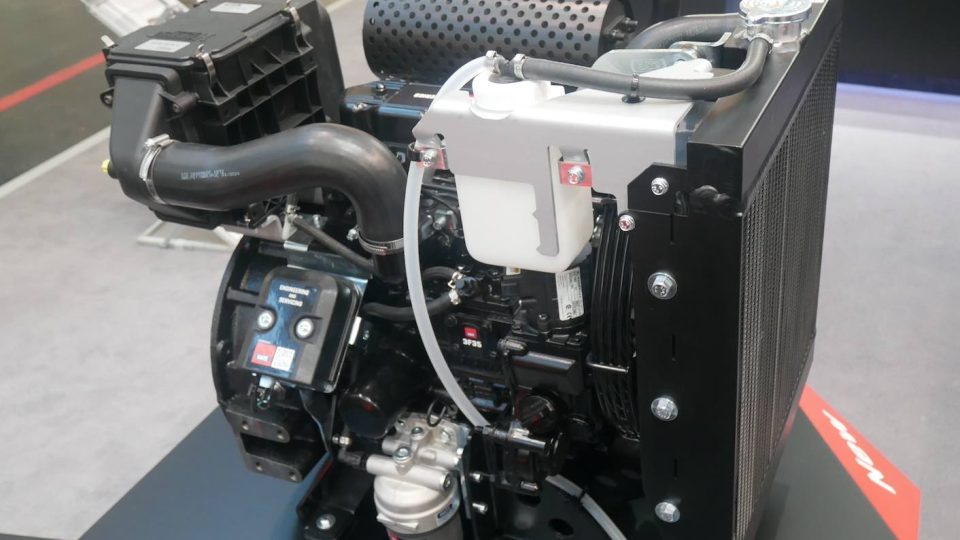

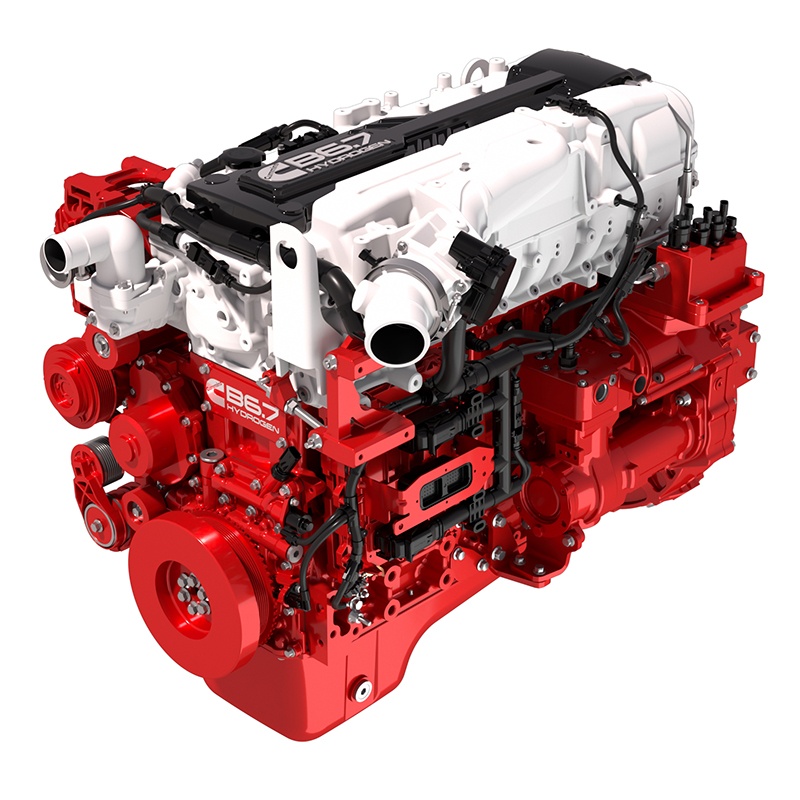

Steve Nendick, Marketing Communication Director, adds: “The hydrogen engine we show here is what we call an agnostic engine. Essentially the cylinder head changes, but the block remains the same, making assembly easier from an OEM point of view. We can offer the use of different types of fuel with the same engine platform: clean diesel, hydrogen, biogas. Biogas has had little uptake in agricultural engine so far, however we are already powering trucks and buses in Europe with natural gas engines so have the expereince. We have just moved our natural gas engine production from the US to Europe so we can better support European OEMs with on-road natural gas engines.”

You’ve been testing tractors in Darlington for a few years. Can you tell us more about it?

Nendick: “These are confidential projects for now that we hope to be able to talk about soon! But I can tell you that, at our technical center in Darlington, we will be opening a new building in July next year. We will be able to test complete vehicles and machines rather than just engine tests. We will be able to test complete drivelines whether they are clean diesel, battery electric, hydrogen fuel cell, or hydrogen combustion engines.”

In agriculture, is Cummins still seen more as a combine supplier (for example, the L9 Barley was developed for these applications) or is there a tractor market share Cummins can aspire to?

Dawson: “The most recent developments you will have seen are our work for the CLAAS TRION and EVION families of combine harvesters, which has been very well received so far. We do power tractors in Canada, USA and South America, sprayers and other special applications around the world. In Europe it has been combine harvesters are the recent success.”

What are the specific needs of farmers compared to other off-highway applications? For example, the size of the ATS or the control of the ECU?

Nendick: “If you look at the L9 engine we have here on the stand, we took the Stage V version and adapted it for use in a combine harvester. So we changed the turbocharging from a wastegate to a variable geometry one. We were able to tailor the ECU and the calibration to make it work at high rpm with a focus on performance and fuel economy needed for harvesters. We manufacture our own turbos and aftertreatment systems, so we can customize the entire system and optimize power delivery and fuel economy for customers. This engine was supposed to debut two years ago at Agritechnica, but the show was cancelled, so it’s the first time we’ve seen it here in Hanover. Each engine specification is tailored to the customer’s needs.”

What aspects do you plan to implement in the agricultural sector, after the innovations seen at Conexpo and at major on-road events such as Iaa and Busworld?

Nendick: “The 6.7 engine we have here is an agnostic engine, with clean diesel, hydrgoen and natural gas capability. It aligns with the platform idea we presented at Conexpo. There we had the 15 litre, but the design solution is the same. We have the smaller engine here as the 6.7 is more suitable for this market. We also present a battery, the BP95E, which we have already revealed at Busworld. We wanted it here to represent our Accelera division. It is important to show the market that we are also carefully investing in new technologies as well as our current products. We want to show a complete portfolio, because today we power so many different vehicles and machines that it is clear that one technology solution cannot be valid for everyone.”