FPT Industrial at Agritechnica: sustainable solutions and the new hydrogen engine

FPT Industrial is currently participating in Agritechnica 2023 (Hannover, 12-18 November), the main world exhibition for agricultural machinery, with its weighted propulsion solutions for agriculture. The big news is the new XC13, the first single-base multi-fuel engine from FPT, presented for the first time in the hydrogen version.

FPT Industrial is currently participating in Agritechnica 2023 (Hannover, 12-18 November), the main world exhibition for agricultural machinery, with its weighted propulsion solutions for agriculture. The big news is the new XC13, the first single-base multi-fuel engine from FPT, presented for the first time in the hydrogen version.

According to the brand’s vision, now more than ever farmers are called to harmonize productivity needs with those of sustainability. This is why the brand reiterates its constant commitment towards the continuous improvement of internal combustion diesel engines, together with the introduction of totally sustainable fuels, such as hydrogen and biomethane, remaining at the forefront in the production of innovative zero-emission electric propulsion systems and hybrid solutions.

A commitment perfectly expressed by the products on display, which visitors can admire in the brand new stand, designed based on the results of a study conducted in collaboration with the Polytechnic University of Milan, which analyzed the global carbon footprint of the stand taking into account, among the other factors, the transport of materials, products and people and energy consumption during the exhibition, set-up and dismantling.

For example, all the materials necessary for the construction of the stand at Agritechnica were transported from Italy to Hanover, and back, by a fleet of Iveco S-Way trucks with Cursor 13 NG engines from FPT Industrial powered by bioLng supplied by Shell, an important step forward towards zero emissions. At the end of the show, residual emissions will be verified to offset them through the purchase of certified carbon credits.

Sylvain Blaise, President of the Powertrain Business Unit of Iveco Group, says: “Our goal is to provide agricultural businesses with the industry’s broadest range of powerful, efficient and sustainable solutions. We are ready to meet the ever-changing needs in all agricultural operations, promoting maximum productivity and future independence from fossil energy. We firmly believe in more sustainable agriculture than ever and the products on display, together with the characteristics of the stand themselves, clearly demonstrate the extent of our commitment”.

FPT Industrial XC13 H2: hydrogen enters the field at Agritechnica

The new XC13, FPT Industrial’s first single-base multi-fuel engine, is presented for the first time at Agritechnica in the hydrogen version. Designed from a common basis and optimized for use with multiple fuels, from diesel to natural gas (including biomethane) to hydrogen and renewable fuels, the XC13 offers maximum component standardization and easy product integration the final.

The XC13 H2 is a technology that adds to the range of FPT Industrial solutions with zero CO2 emissions designed to guarantee customers the same familiarity they are used to with traditional machines. Already successfully used on an off-road vehicle, the XC13 H2 is installed on the Prinoth Leitwolf h2Motion, the first hydrogen snow groomer in the world. This new vehicle concept is in fact equipped with the new 13-litre six-cylinder FPT Industrial XC13 Hydrogen engine, which can count on an exceptional direct fuel injection system.

F28 Hybrid for agricultural applications

The F28 Hybrid uses a diesel engine coupled to an electric flywheel, combining high performance with low fuel consumption in a compact package. This inline four-cylinder engine develops a maximum power of 75 HP, while the electric motor adds another 27 HP of continuous power and 40 HP of maximum power. Thanks to its integrated layout, it is ideal as a plug-and-play solution to replace larger diesel versions. The F28 Hybrid represents the best solution for the effective use of electric agricultural tools, guaranteeing greater efficiency thanks to the compactness of the engine and the optimization of the coupling between engine and tool.It is designed with a scalable modular approach to move from the current 48V P1 architecture to the high-voltage P2 architecture, which allows for greater power output and the use of plug-in solutions in zero-emission applications (indoors, stables, greenhouses).

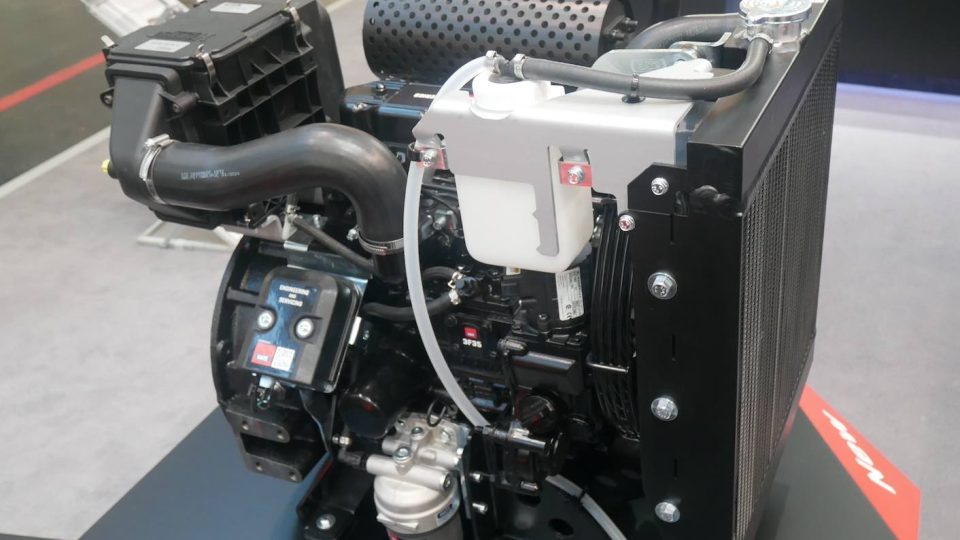

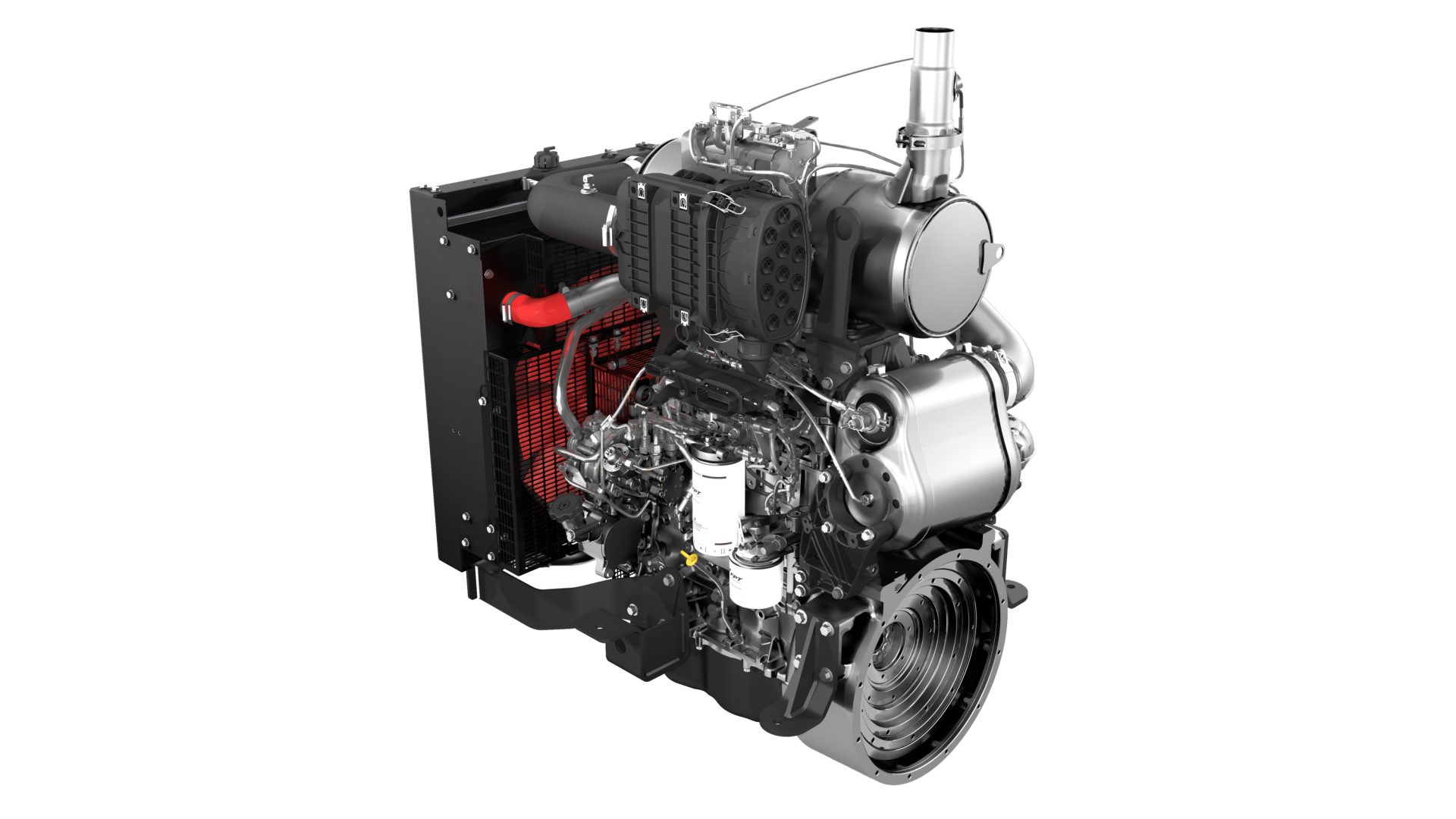

F36 Industrial Power Unit (Ipu)

The F36 PowerPack Stage V is an integral part of the vast offering of FPT Industrial thrusters and represents a powerful, flexible and reliable solution for stationary and semi-stationary applications. The compact engine-mounted ATS package, which also includes the urea injection system and all necessary sensors and manifolds, eliminates the need to develop a dedicated exhaust system. A range of options, including alternators, starters, water and air preheating systems and urea tanks in different sizes, provide even greater flexibility for customer installations. Single-sided access allows for quick and easy servicing, while the 600-hour maintenance interval maximizes uptime.

eBS42, the battery pack for off-road

The ever-increasing interest in electrified solutions in the agricultural sector leads to the demand for specific and technologically advanced battery packs, capable of dealing with the great variety of field and road operations typical of modern agriculture.

Created in collaboration with Microvast, designed and developed to best meet off-road needs, the FPT Industrial eBS42 battery pack presented at Agritechnica represents a cutting-edge zero-emission energy storage solution for the agricultural sector.

Thanks to the best-in-class energy density for top performance and the high level of flexibility offered by its multipack configuration, this battery pack can be installed on various types of agricultural machinery, to satisfy various usage profiles and meet the different needs of the customers.

N45, the NEF for the agricultural sector

A cornerstone of the NEF engine family, with over 2 million units produced since 2001, the N45 is a robust, reliable and versatile engine that offers a wide variety of configurations and options to meet all agricultural needs and facilitate installation in off-road machinery. Presented for the first time in the 147 kW version, dedicated to the most demanding agricultural applications, the N45 owes its constant success among farmers to its high efficiency, EGR-free and maintenance-free ATS layout and maintenance intervals at the top of the category up to 1,200 hours. All these unique features contribute to reducing the total cost of ownership of a wide range of agricultural machinery.

N67 NG, the natural gas version for zero-emission agriculture

With over 20 years of experience and more than 80,000 units sold worldwide, FPT Industrial is at the forefront of natural gas technology for off-road applications, with customized solutions specifically designed for agricultural machinery.

The N67 Natural Gas engine represents the most technologically advanced solution in terms of clean energy engines developed specifically for open-field tractors. In fact, with the use of biomethane, CO2 emissions are almost or completely eliminated, thus allowing the creation of circular ecosystems in agriculture.

In terms of power, torque and durability, the N67 NG offers similar performance to the diesel version, ensuring the same level of efficiency and drivability in the field for an uncompromising customer experience while reducing the carbon footprint of agricultural operations. The N67 NG is used on the New Holland T6.180 Methane Power, winner of the “Sustainable Tractor of the Year 2022” title.