Kodiak and John Deere. A snowy landscape looks gorgeous

Kodiak is ready to approach the winter time, together with John Deere Power Systems. What does it mean? The winter season has just begun and in certain areas of the planet snowstorms are able to block, or make impervious, any human activity. Kodiak America powered some snow blowers with John Deere PSS9.0L and PSS13.5.L diesel […]

Kodiak is ready to approach the winter time, together with John Deere Power Systems. What does it mean? The winter season has just begun and in certain areas of the planet snowstorms are able to block, or make impervious, any human activity.

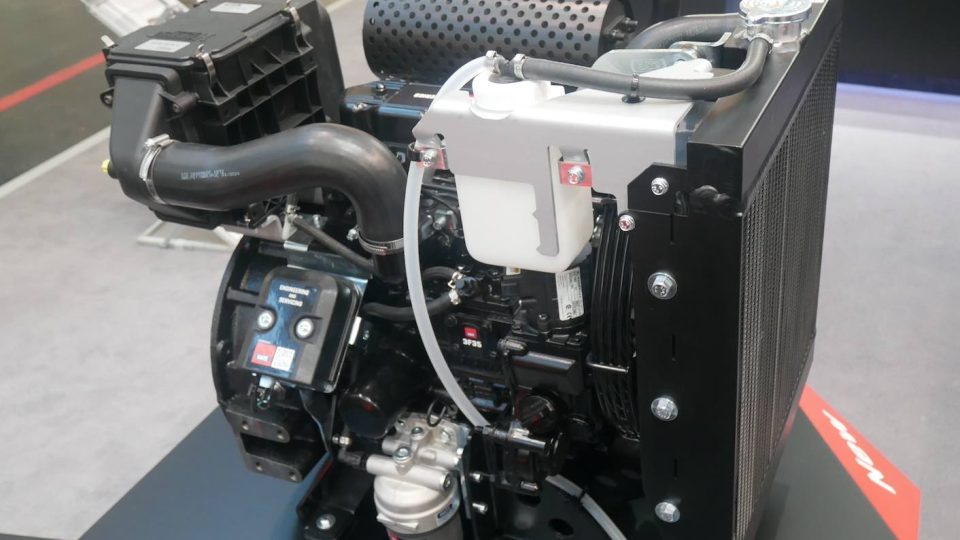

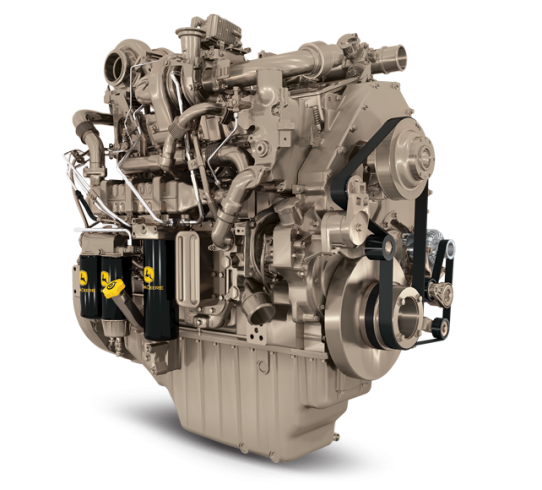

Kodiak America powered some snow blowers with John Deere PSS9.0L and PSS13.5.L diesel engines.

Kodiak America likes the Deere

Such as Brek Pilling, Kodiak manager, said: «Our snow blowers will cut through avalanche zones, where there’s rock and tree limbs, without seriously damaging the snow blowers. We are constantly looking for technologies to improve the strenght and durability of our snow blowers».

DEERE FEELS COMFORTABLE WORKING OUTDOOR: WACKER NEUSON

It’s not just matter of Santa Claus, his reindeer and the kids on the sleds. Technology is needed to keep the roads clean from the snow and prevent the formation of ice on the asphalt.

Among the other features, snow blowers have oil-less poly Kevlar belt drive system that transmit power to a steel alloy reel. Machines are available loader-mounted such as self-propelled Crs.

Talking about Cascade engine center, the John Deere Power Systems distributor, Pilling says: «If we need to make some changes, they have a very flexible, accommodating in-house engineering staff to help us problem solve. We are noticing that the Final Tier 4 engines don’t fall off as quickly. It allows you to put a lot more load on the snow blower».

Kodiak and John Deere. An American deal

13.5 liter engine is the John Deere top of the range and it covers the power level between 298 and 448 kilowatts, needed to move 1,361 to 4,536 tons of snow an hour and cast it up to 61 meters.

AND THE NEXT TOP ENGINE IS? 13.6 LITERS, OF COURSE

Tier 4 Final engines request after-treatment system, that includes SCR.

Is it a tough task to use DEF (Diesel Exhaust Fluid) for such applications as snow blowers?

How to avoid the risk of crystallization of technical urea?

This is the answer by John Deere: «DEF starts to freeze at minus 11 degrees Celsius. John Deere uses electrically heated lines between the DEF tank and the decomposition tube during operation in cold ambient temperature, allowing uninterrupted injection of DEF into the exhaust stream».