Liebherr to premiere its hydrogen prototype engines at Bauma 2022

The Liebherr components product segment introduces the first prototypes of hydrogen combustion engines, the H964 and H966, at this year’s Bauma

At Bauma 2022, the Liebherr components product segment is introducing two prototypes of its hydrogen engine for tomorrow’s construction sites. Each prototype employs different hydrogen injection technologies, a direct injection (DI) and a port fuel injection (PFI).

In the future, combustion engines will no longer be powered solely by fossil diesel. In order to achieve climate neutrality by 2050, fuels from sustainable energy sources will have to be used. Green hydrogen is one of them, since it is a promising carbon-free fuel, which does not cause any CO2 emissions whilst burning inside the internal combustion engine (ICE). Liebherr’s expertise in the development of ICEs will furthermore facilitate a quick introduction of hydrogen technologies to the market.

Liebherr hydrogen engines: a promising future

The Liebherr components product segment has recently made a significant investment into the development of its hydrogen engine and test facilities. Prototype engines have been tested since 2020. Meanwhile, the prototypes have shown encouraging results in terms of performance and emissions, both on test benches and in the field. Different injection and combustion technologies, such as port fuel injection (PFI) and direct injection (DI), have also been assessed in the process. The first prototype construction machines equipped with these engines have been running since 2021.

PFI technology: a starting point in the development

Initial efforts in the development of a hydrogen engine have considered PFI as a first suitable technology. The first machine running with a 100% hydrogen-fuelled ICE is the Liebherr R 9XX H2 crawler excavator. In it, the zero-emission 6-cylinder engine H966 fulfils the specific requirements in terms of power and dynamics. The R 9XX H2with the H966 engine in its port fuel injection configuration will be on display at booth 809-810 and 812-813. Up close, the H966 will be presented there in the InnoLab.

DI: a step towards efficient hydrogen engines

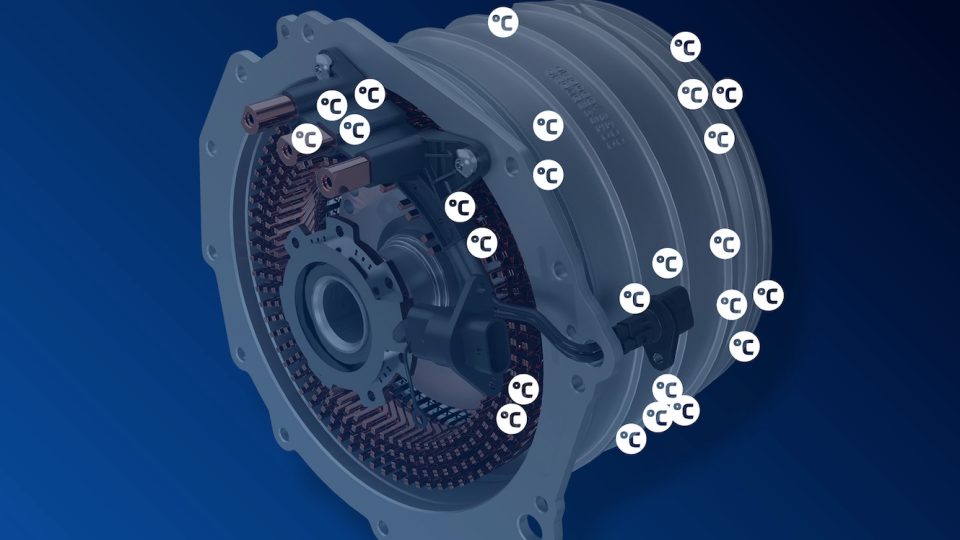

Encouraged by the results achieved with the PFI technology, Liebherr further pursues its research and development activities in the field of DI. The 4-cylinder engine prototype H964 exhibited at the components’ booth 326 in hall A4 is equipped with said technology. In this case, hydrogen is injected directly into the combustion chamber, whereas with the PFI solution it is blown into the air intake port. The DI offers increased potential in terms of combustion efficiency and power density, which makes hydrogen engines an attractive alternative to diesel engines when it comes to more demanding applications.

What is next to come?

The components segment expects to kick off series production of hydrogen engines by 2025. In the meantime, the company sets forth its research activities in fuel injection to further optimise combustion and to ensure maximum power density.

In addition to 100% hydrogen-fuelled engines, several research endeavours in the area of alternative fuels are currently in progress. One example is a dual fuel engine that can run on hydrogen ignited by HVO injection or fully on HVO. This technology will allow for more flexibility in vehicle operation with different configurations.