Linde Material Handling renews the range of thermal front forklift trucks with new models from 3.5 to 5 tons

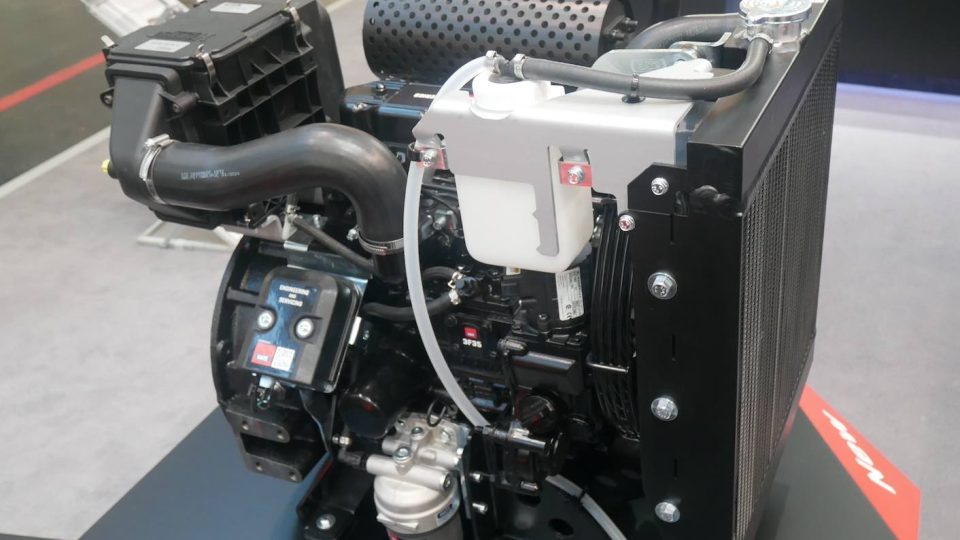

Powered by a diesel, LPG or methane engine, the new Linde forklifts can better satisfy many applications. Compared to previous models, they guarantee greater residual capacities, facilitate the handling of materials and reduce consumption, offering comfort, visibility and safety.

Powered by a diesel, LPG or methane engine, the new Linde forklifts can better satisfy many applications. Compared to previous models, they guarantee greater residual capacities, facilitate the handling of materials and reduce consumption, offering comfort, visibility and safety.

The combination of superlative performance, sturdy structure and great maneuverability makes the use of forklifts powered by Linde combustion engines essential for many sectors, from intralogistics to the mechanical industry, from construction to paper industries, up to large-scale distribution. Safe, reliable and versatile, these trolleys can perform numerous tasks, such as moving dozens of beverage crates in one operation, handling load units weighing several tons, transporting heavy loads such as building materials, handling heavy pieces of steel, lifting wire spools or storing paper spools or bales of waste paper.

“Many areas of application cannot renounce the use of forklifts powered by thermal engines – explains Duilio Compagnoni, Product Manager Linde MH Italy –, which offer important advantages such as ease of refueling or the exclusive Linde hydrostatic transmission system, which ensures maximum sensitivity and ease of use and the best possible control in all goods handling operations.”

To meet the market demand for these models, Linde Material Handling has enhanced its range of thermal trolleys, also introducing a smaller model, with a load capacity of 3.5 tons. The new generation of Linde H35-50 trolleys – powered by diesel, LPG or methane engines – guarantees greater pallet handling capacity, offering better comfort, expanded visibility, protection systems for both the operator and the environment and a powerful transmission system.

Unlike the previous series, the new models have been designed with a load center of 600 mm, which ensures high residual capacities even when using typical attachments and applications for this range, such as the use of fork positioners or grippers for any kind of application. The Linde H50 model, with a load capacity of 5 tons, also offers the possibility of a load center of 500 mm. Thanks to the ground clearance of 207 mm (on Linde H35 and H40 models) and 250 mm (for H45 and H50), the new trolleys can be used outdoors without any contraindications, even on muddy surfaces or on irregular floors or grounds.

“The renewal of the range of thermal trolleys responds to the customer’s request for increasingly reliable, powerful and versatile forklifts – explains Compagnoni –. All this guaranteeing the maximum safety and comfort of the operators. Many of Linde’s most advanced safety features are in fact supplied as standard, such as the electronic safety belt closure monitoring system, Linde Load Assist, which detects the weight of the load, and Linde Curve Assist, which automatically reduces cornering speed.”