Bobcat turns sixty

Bobcat: sixty years of successes Sixty years ago, when Bobcat did not exist, the Melroe Manufacturing Company started a tradition that has lasted uninterruptedly ever since. At that time, a front loader was launched, whose evolution is known today as Bobcat. At the time, the first compact non-steering wheel loader was named M-400. Only later […]

Bobcat: sixty years of successes

Sixty years ago, when Bobcat did not exist, the Melroe Manufacturing Company started a tradition that has lasted uninterruptedly ever since. At that time, a front loader was launched, whose evolution is known today as Bobcat.

At the time, the first compact non-steering wheel loader was named M-400. Only later it adopted the name that today has become the icon of compact machines. His fame has grown to such an extent that today, on every two compact loaders sold, one features the Bobcat brand. Over the course of six decades, compact tracked and four-wheel steering loaders have been added to the family.

Compact excavators and telescopic lifters represent one of the most prolific ramifications of the brand. A wide range of accessories completes the family. In 2017, Bobcat’s compact excavator market crossed the 30-year threshold. The most recent achievements in the sector, the 2-4 ton compact excavators, the result of the work of the Innovation Center, will debut at the next Intermat in Paris.

Out of national borders: Emea

Today, in geographical terms, Europe, the Middle East, and Africa host integrated and complete production facilities. From the designing phase to manufacturing. The process of progressive diversification of the Bobcat product range had to pass from Europe. Over the last twenty years, the settlement in the old continent has provided the house with the necessary impulse to cross the productive boundaries of compact loaders.

The opening in 2007 in Dobříš, in the Emea area (Czech Republic), of the first production center outside the United States was fundamental. After a short time, Doosan Infracore took over Bobcat from the previous owner, the US Ingersoll Rand. The acquisition turned out to be positive, and consequently, Bobcat’s business volume in the Emea area grew. Between Dobříš and the French production area of Pontchâteau, Bobcat produces over 80% of the products destined for the region. The telescopic center in Pontchâteau celebrates its 55th birthday this year. What better way to celebrate than by extending the production of telescopic lifters to agriculture and construction?

The Middle East

The opening of the first Bobcat center in the Middle East (Dubai) dates back to 2008. In 2015, a spare parts distribution center, also in Dubai, followed. The choice was the result of the desire to have a first outpost for the Middle East and Africa. Also in the same year, in Dobříš the Innovation Center, a European excellence for engineering services, started operating. The center has become a reference in the Emea area, for it is specialized in research and development, specifically dedicated to small-sized loaders and compact excavators from one to three tons.

Innovation at the center of the Emea region

The Doosan Bobcat Camp in Dobříš stands out from the other numerous production centers of the company. It includes the innovation center, the logistics center, and the training center, in addition to the assembly lines. The new serial products come to production in this technological center. Also the customers of the region are managed in here, in addition to the dealerships. Between 2016 and 2017, Bobcat also launched two ranges of backhoe loaders. The first for the Middle East and Africa, the second for the Russian and Csi countries. In doing so, it has further strengthened its presence in the Emea area.

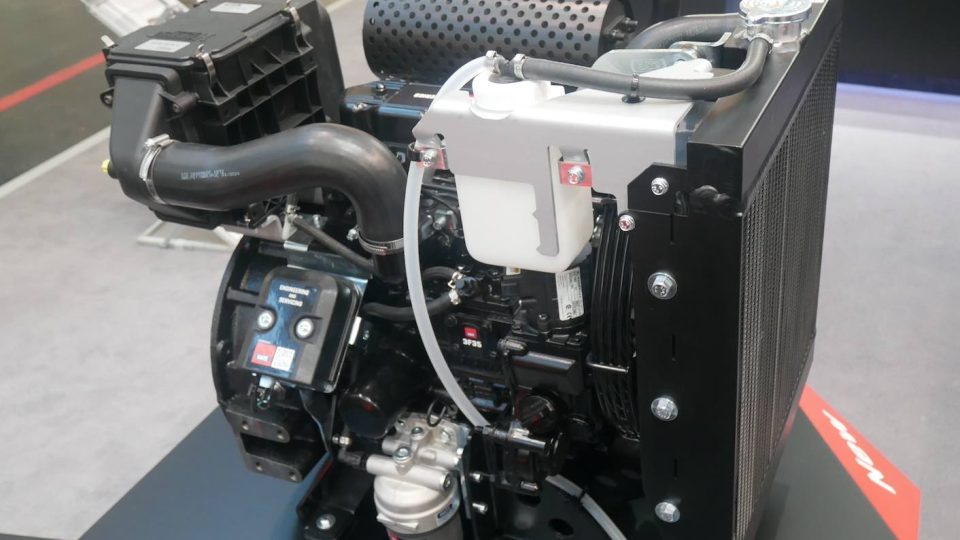

Doosan Infracore means engines

Doosan Infracore presented itself between the end of 2012 and 2013 with the credentials to receive critical and market consensus. The triad D18, D24 and, D34 (the abbreviation corresponds to the displacement) should have met the propulsive needs of Bobcat. Compact size, power and torque average, a balance of 50,000 units/year, 100,000 at full capacity. Things did not go exactly like that since only recently the Koreans arrived under the Bobcat hoods. But the times are ripe for the big jump of Incheon’s trio in the free market.