Caterpillar CHP: for today and tomorrow

Tom Smith, Caterpillar Gas Segment Manager, spoke about Caterpillar CHP, introducing the company’s vision on cogeneration. You can read the full article in the May issue of Powertrain

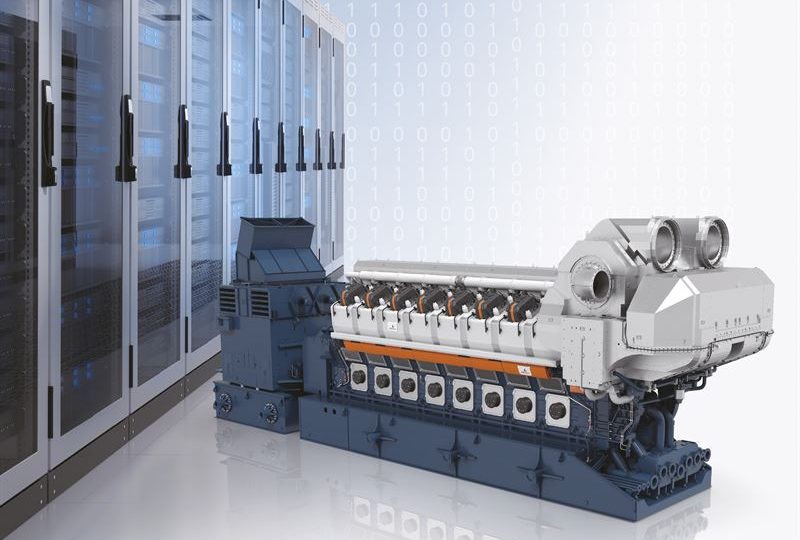

We reported on Caterpillar power generation in the January issue, about a data centre in Quincy, Washington, US. Now we tell you about a webinar in which Lou Signorelli, Caterpillar Electric Power, moderator, and Tom Smith, Caterpillar Gas Segment Manager, spoke about Caterpillar CHP.

“We’re going to talk about what exactly CHP is,” Smith said. “CHP has been a reliable, sustainable energy solution since 1882, when one of the world’s greatest inventors, Thomas Edison, built the first CHP plant in New York City that was producing electric power for the downtown New York grid at the time. Over the years Caterpillar, with our sister company Solar Turbines, has put in over 33,000 MW of CHP applications. What’s happening with all of the changes in the power industry, with transportation being electrified (in fact even with Caterpillar Equipment we’re electrifying mining equipment to obviously reduce greenhouse gases), is driving up the need for reliable clean energy. If you take a look at a conventional way a hospital gets electric power, you know you have a power plant that would be remote to the facility, there would be transmission and distribution losses before the electric power got to the site, then the site in order to produce heating would have a boiler for hot water or steam and that would require in a traditional power plant almost 10,000 tons per year of CO2. If you put a CHP system generating the electricity on site you’re using the waste heat, you’re seeing almost a 51% reduction in greenhouse gases.”

Lou Signorelli introduced the topic of energy saving and reduction of harmful emissions. How does CHP reduce emissions even when the engines are using natural gas as a fuel?, he asked.

Tom Smith gets to the heart of the matter. “If you look at a CHP operating super efficiently, you are saving a lot of the greenhouse gases because you’re using all of the waste heat. That is going to be even more and more prevalent as we look at alternative fuels of the future like hydrogen, where you can have super efficient CHP facilities with zero emissions. A key consideration with any investment nowadays is it has got to make economic sense. CHP has always made economic sense in most areas because it’s very efficient. In the US we have investment tax credits and a lot of federal and local incentives. Taking a look at another key advantage of CHP, we’re seeing a lot of different weather events that occurred and knocked out power in a number of facilities all over the world, so having reliability is key and that’s one of the real benefits that CHP can offer. Any industry that could use that heat either to produce hot water or steam or converting it to chill water is a perfect fit for CHP: district energy facilities, hospitals, landfills, greenhouses, government facilities, data centers, water sewage plants, mining electric utilities… There’s just a vast amount of applications for CHP. When I got into the CHP business in the early 80s, a lot of the initial adopters of CHP were the high electric power users and people that had massive amounts of thermal energy, like oil refining and chemical manufacturing, now CHP is growing into other markets as we talked about greenhouses and hospitals because they’re looking at the resiliency. Historically data centers have looked at just having 100% backup provided by diesel engines and not using the waste heat because of efficiency, the need for capacity, the high volume of cooling that’s required in data centers. A couple of examples: we put a cogeneration project in the WR Grace Davison Chemical Division. They have over 22 plants throughout the world, one of their largest facilities in Curtis Bay, Maryland, had been in operation since 1910. They put a CHP plan that was basically sized for the thermal use that they had for the heating and some hot water requirements. Even though the plant had a peak load of almost 15 MW, they installed a 5MW CHP plant with some of our engines capturing the waste heat for hot water production that’s used in the facility. It really helped WR Grace meet some of its sustainability goals, reducing annual GHG emission of 14,415 tons.“

You can read the full article in the May issue of POWERTRAIN