Himoinsa supplies emergency power to Norway’s Ålesund Hospital

Himoinsa generator sets, supplied through Østerbø Maskin AS, the company’s distributor in Norway, are used to guarantee emergency power in the event of a grid outage at the Ålesund hospital.

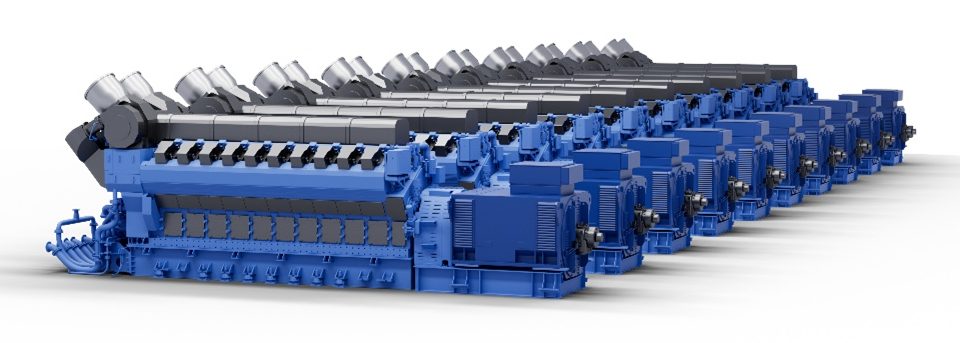

Ålesund hospital, which provides healthcare coverage for a population of some 50,000 people, has installed three Himoinsa HTW 1530 T5 generator sets to cover its emergency power requirements and to ensure a supply of critical power in the event of a grid outage. As the city is built on a number of islands and subject to adverse weather conditions, the project’s design and development have had to take these environmental requirements into consideration.

The hospital was first opened in 1971 and already had a number of emergency generator sets, hence the objective was to replace them with new Himoinsa models housed in a soundproofed room in order to reduce sound levels to the maximum.

The generators have been installed, guaranteeing a total of 4MW of power in what is a mission critical project designed to ensure operational continuity in all areas of the hospital in the event of a grid outage. One of the project’s major challenges was to undertake the installation of the generator sets with the new 400V and 230V distribution systems in phases, ensuring that the hospital was fully operational at all times.

Safety: redundant power system

The project has entailed the construction of a new external building, next to the hospital, in which the generator sets and the emergency switchboard have been installed. In order to increase the safety and efficiency of the equipment, certain essential requirements were met, such as ensuring that the installation was a redundant system and that the generators worked in parallel, i.e., a N+1 design, thereby guaranteeing that should one of them fail to start up, another generator will always be able to do so and to supply power to the healthcare complex.

The new emergency genset building runs on a 690V system suppling the 400/230 transformers. A special system of transfer and control panels required by the client has been delivered. Along with the three generator sets’ control unit, the main switchboard control system features a touch screen which is connected to the three transfer switches that feed six different connections of the hospital’s installation, located in three different places. Everything has been installed within a redundant fibre-optic ring for communicating and responding to the installation’s different demands.

Himoinsa: ensuring low noise emissions

Given the need to comply with strict regulations in terms of noise levels and due to the fact that this facility is very close to a residential area, one of the requirements was that the sound level should not exceed 69dB@ 1m on the outside of the building. To achieve this level of sound attenuation, specific measures have been taken such as the installation of sound attenuation panels, based on the engine specifications, as well as three 14-metre-long chimneys, each of which is connected to a powerful silencer.

The sound attenuation solution was designed by Østerbø and has been verified by an external acoustician who has ensured that the proposed system not only meets the requirements of the emissions regulations, but also in terms of pressure loss, thus ensuring that sufficient cooling capacity is available.