Mammoet: heavy engines transported using efficient plug-and-play solution

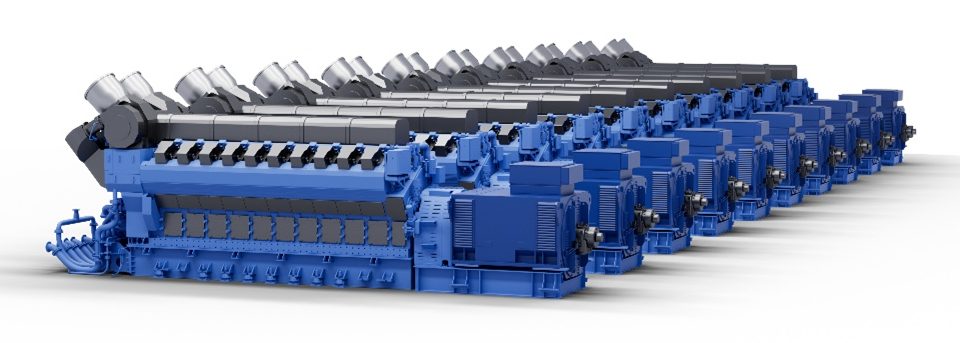

When Mammoet was approached by freight forwarder UTC Overseas to assist with the transportation of eleven 287t engines to a remote location in San Antonio, Colombia, it quickly determined that the obvious route wasn’t necessarily the most efficient. The engines were required for the construction of a new 200MW power plant by the energy company Celsia. Watch the video here.

When Mammoet was approached by freight forwarder UTC Overseas to assist with the transportation of eleven 287t engines to a remote location in San Antonio, Colombia, it quickly determined that the obvious route wasn’t necessarily the most efficient.

The engines were required for the construction of a new 200MW power plant by the energy company Celsia. The isolated location of the site was chosen due to proximity to the gas source and to help bring jobs to the local area. The client had initially considered receiving the engines at one of the region’s two main ports (Cartagena and Barranquilla), which would typically handle operations of this type.

There was also a question around the best method to transport the engines, as Edilber Guerrero, Mammoet Sales Manager, explains: “At first, the client was thinking it wasn’t possible to transport the engines fully assembled to the job site. They were considering dismantling them into two pieces. With smaller pieces it is easier to transport, so this was their initial plan. Of course, the downside to this is that you would then need to build the engines on site, so you need more time, more people, more resources and money. The scale of the project would double.”

The public port of Compas in Tolu is closer to the site but is typically used for loading and unloading coal vessels, not heavy load cargo. Receiving the engines at Cartagena (the closer of the two main ports) added 100km to the journey and further road restrictions.

The solution that Mammoet proposed was to use the port of Compas and an alternative route of secondary roads. This would allow the operation to be carried out more efficiently and with complete engines.

The first challenge was to prove to the authorities that the port of Compas had the capacity to receive the engines. Of particular concern was the connection bridge between the quay and the land and whether it could handle the exceptional load.

Mammoet engineers successfully carried out all the verifications to prove that the port and the bridge was suitable for the operation. The engines were then shipped from Europe on a single vessel to the location. Upon arrival, they were transshipped, via crane, from the vessel onto conventional 20-axle line flatbed trailers with a prime mover and then transported to a holding area inside the port. From there, they were delivered, by road, to the site in convoys of three.

The team had already determined that the main highway would not be suitable for the cargo, due to the presence of towns (such as Sincelejo) and a long bridge (approx. 100m) with insufficient load capacity. Therefore, they proposed an alternative route to bypass these restrictions.

The route consisted of unpaved narrow roads, so modifications were carried out. The roads were levelled and compacted, and vegetation trimmed back. Wire-relief teams were also used to lift and temporarily disconnect low-hanging cables.

One of the biggest challenges was transporting the heavy cargo across five weak bridges. Support ramps were installed to allow the convoy to travel safely across them without overloading. When the convoy eventually joined the national road, it entered populated urban areas and faced different challenges.

“We had to manage traffic, people and liaise with the local authorities to agree the exact times that we were going to cross the towns,” says Edilber. “Coordination with the local communities became the challenge. In advance, we lifted as many of the cables and removed roadside obstacles, such as billboards, but there were still a few cables that had to be raised during transit.”

When the convoy finally arrived at the site entrance there was another challenge to overcome. The road leading to the site had a small weak bridge, so steel columns were installed to reinforce it and allow the cargo to pass. Inside the site there was little space to maneuver, so the cargo was transshipped onto Mammoet Self-Propelled Modular Transporters (SPMTs). This allowed the tight turns needed to install the engines into their final positions, which was completed using a track-and-slide system. Mammoet’s plug-and-play solution was successful in finding efficiency, not only in the port used but the route taken. It allowed for all eleven engines to be transported as complete units; avoiding the need for any assembly to happen on site.

With the project now complete, it is one that perfectly demonstrates how Mammoet’s involvement in specialist logistics operations can bring significant benefits in terms of time, efficiency, cost and scale.