Volvo Penta, 17 highlights of D17 industrial genset engine

Volvo Penta’s most powerful engine – the D17 – supports the current business needs of industrial customers as well as their future demands as they navigate the energy transition towards decarbonization using renewable fuels.

Volvo Penta’s most powerful engine – the D17 – supports the current business needs of industrial customers as well as their future demands as they navigate the energy transition towards decarbonization using renewable fuels.

- Fuel Efficiency: Compared to the D16 model, the new D17 offers up to 5% less fuel consumption per kWh due to recent evolutions in combustion technology, such as the modernization of the fuel-injection system with a common-rail design.

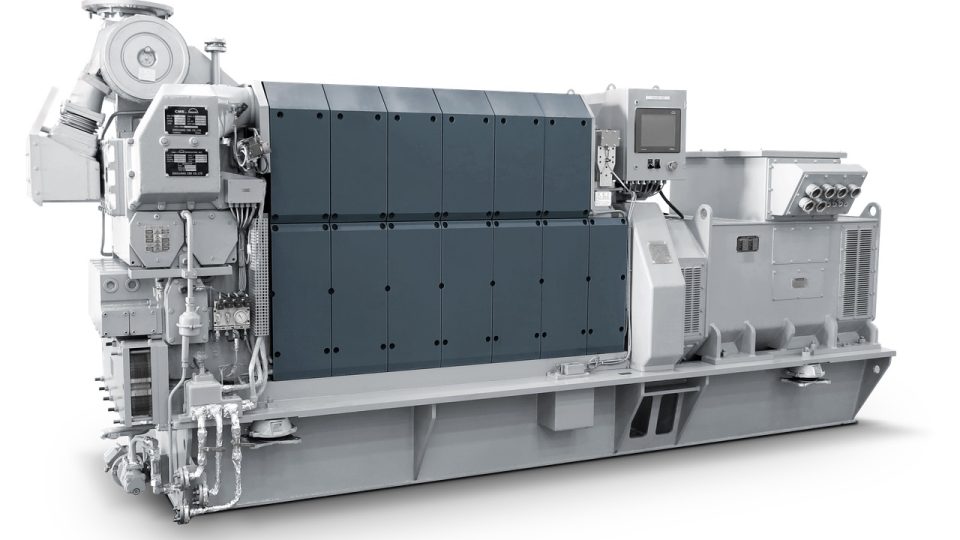

- Weight Optimized Design: A compact and low-weight design is well-balanced, providing smooth operation with low noise and vibration and an overall easy installation, service and transport.

- HVO Compatible: Volvo Penta is actively investigating alternative fuels and various technologies. Currently, all Volvo Penta engines, including the D17, can run on HVO (hydro-treated vegetable oil).

- Cooling Package: Add the option of a viscous fan and air-filter that will suit a variety of installations and further reduce fuel consumption and noise emissions.

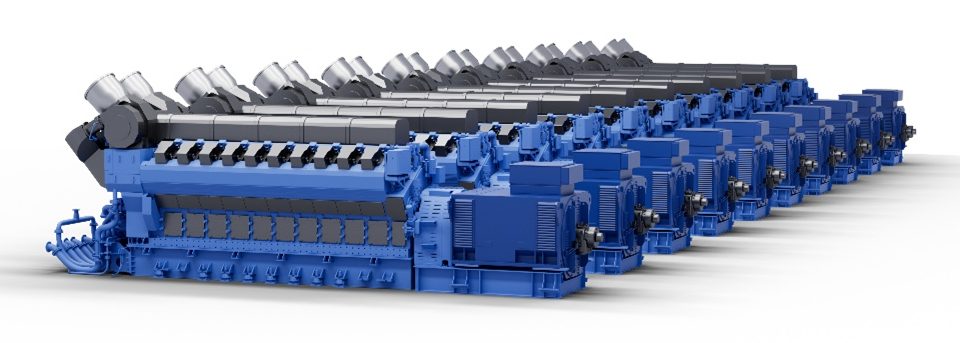

- Power Density: The 17-liter diesel engine uses dual-stage turbochargers and heavy-duty steel pistons, making it optimally designed to power a wide range of stand-by (up to 881 kVA) and prime power generator sets (up to 758 kVA).

- Prepared for the Future: The D17 – together with the rest of the Volvo Penta power generation line-up – will evolve to enable customers to transition to significantly lower well-to-wheel emissions using renewable fuels.

- TCO: The D17’s extended service and oil change interval of 1,000 hours, low heat rejection, serviceability, and spare part commonality, can all contribute to keeping expenses down.

- Load Acceptance: The D17 complies with the most-stringent ISO8528 G3 standard for load acceptance, indicating that it can meet power demand in response to a blackout.

- Emissions: The D17’s exhaust emissions comply with UNECE REG 96 Stage 2 (equivalent to EU Stage II mobile off-highway requirements).

- Certification Standards: Our most powerful industrial genset engine is certified for US EPA Tier2 Stationary Emergency, enabling it to be used for supplying a few hours of back-up power in some highly regulated regions.

- Enhanced Volume: Volvo Penta engineers developed a larger bore engine for the D17, which enabled the larger volume compared to the D16 and led to a 10% increase in maximum standby power over the TWD1645GE at 1800 rpm.

- Warranty Options: Depending on where your industrial operation is in the world, Volvo Penta offers customers engine warranty options, delivering confidence and peace of mind.

- Dual Speed: The dual-speed (1500/1800 rpm) D17 is suitable for a wide range of applications, most notably where sufficient back-up electrical power must always be available.

- Single Supplier: As an independent supplier, all Volvo Penta products are a complete solution – designed, tested, manufactured, warranted and serviced by one company and network.

- Aftermarket Support: Take advantage of an extensive global network of dealers to secure performance and uptime. Volvo Penta can support projects throughout the lifetime of the machines.

- Seamless Integration: The D17’s sister engine, the D16, with an inline six-cylinder block, provided the starting block for the new design, ensuring the D17’s basic footprint would remain the same.

- Partnership Potential: Choosing the D17 includes more than just the engine itself. With your application in focus, a Volvo Penta partnership entails collaboration all the way from the design stage to aftermarket service.