Cummins and Accelera at ConExpo: the hydrogen strategy

Cummins confirmed its commitment at ConExpo to playing a major role in the hydrogen economy as part of its Destination Zero initiative and recent launch of Accelera by Cummins, a new brand unveiled last week representing a quickening pace of bringing zero-emissions solutions to market.

Cummins confirmed its commitment at ConExpo to playing a major role in the hydrogen economy as part of its Destination Zero initiative and recent launch of Accelera by Cummins, a new brand unveiled last week representing a quickening pace of bringing zero-emissions solutions to market.

“Cummins has developed leading power solutions for over a hundred years, and we continue to demonstrate our leadership in developing a broad range of sustainable drivetrains looking to the future – with hydrogen playing a key role,” said Antonio Leitao, Cummins VP Off-Highway Engine Business. “Our strategy is to focus on the complete hydrogen value chain to drive sustainability and enable faster adoption.”

As a result of acquisitions and investment, Cummins is focusing on three key areas for hydrogen: the production of green hydrogen, the management and transportation of hydrogen, and the application of hydrogen in engines and fuel cells.

“Accelera is committed to raising awareness of the flexibility and dependability of hydrogen and fuel cell engines,” said Alison Trueblood, General Manager of Fuel Cell and Hydrogen Technologies for Accelera. “We are building long-lasting partnerships with our customers based on the shared knowledge that the best power solutions of the future are zero-emissions.”

Cummins and Accelera: green hydrogen production

Green hydrogen is produced using electrolysis to turn sustainable power (wind, solar, hydro) into hydrogen with zero carbon dioxide emissions. The key tool to do this is an electrolyzer. Accelera is establishing new electrolyzer plants in La Mancha, Spain and Minnesota, USA as well as expanding production at Oevel, Belgium and Mississauga, Canada. With over 600 electrolyzers deployed globally in 100 countries Accelera’s investment is growing in this technology. One of the latest projects includes providing a 35-megawatt (MW) proton exchange membrane (PEM) electrolyzer system for Linde’s new hydrogen production plant in Niagara Falls, New York. Once commissioned, Accelera’s electrolyzer system will power Linde’s largest green hydrogen plant in the U.S. On display is Accelera’s 1500E stack which forms part of a 2.5 MW PEM Electrolyzer.

Hydrogen storage and supply

On-board storage is a critical component of hydrogen power. Hydrogen needs to be compressed into the available space to store enough to meet vehicle duty cycle requirements. Cummins has a joint venture with NPROXX, a world leader in high pressure hydrogen storage for both stationary and mobile applications, to support the OEM integration process. Storage tanks will have a 700-bar pressure capability to maximize capacity and operating range.

“Supply and infrastructure will take time to develop. Adoption of hydrogen will likely begin with applications where fueling can be done centrally such as at home base operations or close to large hydrogen hubs,” commented Leitao.

Hydrogen engines and fuel cells

Cummins is developing hydrogen powered combustion engines which will provide sustainable solutions that are more aligned with current vehicle designs to reduce complexity for OEMs and their customers. The reuse of appropriate components drives economies of scale while also providing reliability and durability equal to diesel.

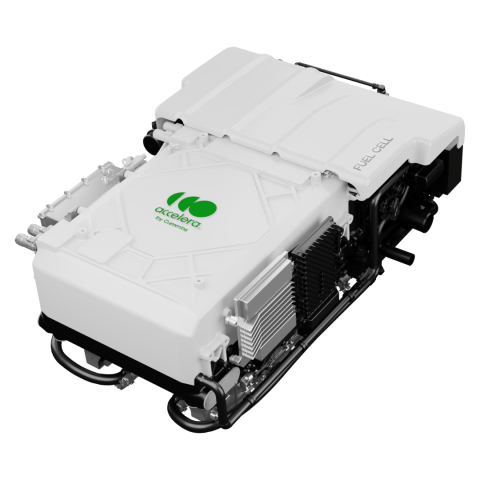

Hydrogen fuel cell technology can offer an efficient power solution for heavy-duty vehicles with high utilization and energy demands, while meeting zero-emission needs. The fuel cell uses oxygen to create a reaction, turning the hydrogen into electricity. It works alongside battery technology – ultra-capacitors, lithium-ion, or lead-acid – in a parallel hybrid set-up to deliver instantaneous response.

Accelera displayed its fourth-generation fuel cell engine at ConExpo which provides improved power density, efficiency and durability while delivering zero greenhouse gas and zero criteria air emissions. It is available in single 150 kW and dual 300 kW module engines for heavy-duty off-highway applications.

“We see hydrogen engines and fuel cells as complimentary power sources, offering different options to customers depending on where they are on their path to zero carbon. Introducing hydrogen engines in the market will also accelerate the growth of hydrogen infrastructure to support the widespread adoption of fuel cell powertrains,” concluded Leitao.