DAM and the path to hydrogen

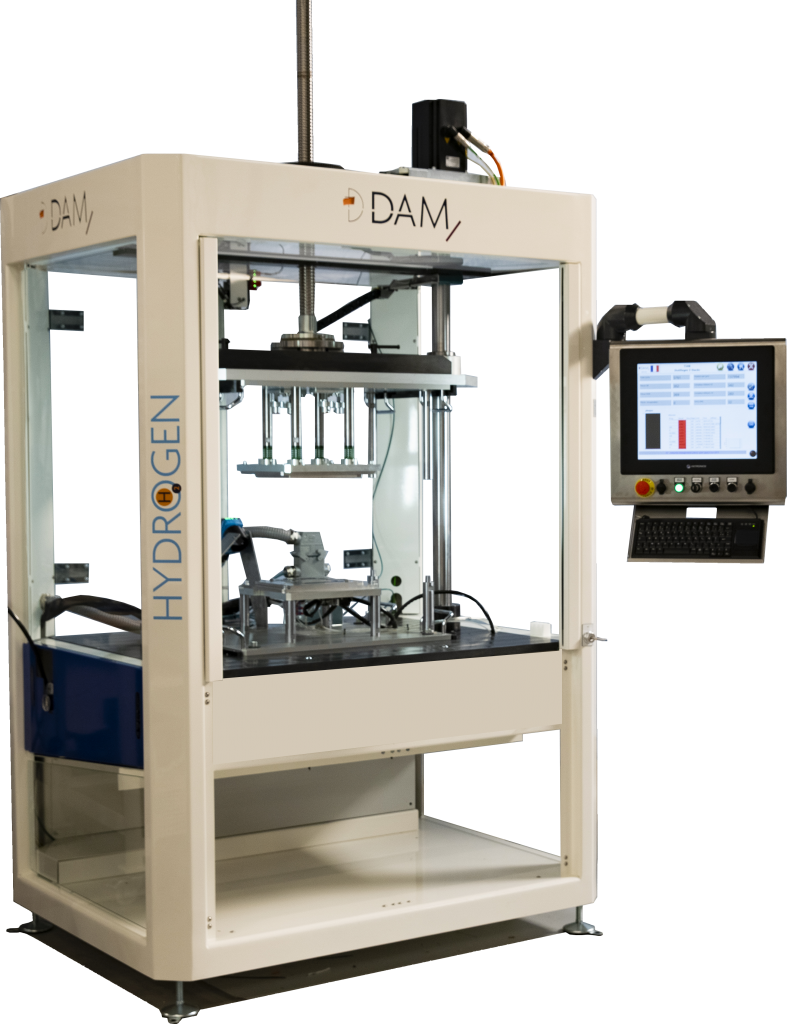

If you say ‘DAM’, we reply ‘hydrogen’ (Do you remember the agreement between Volvo and Daimler?). Why? You must know that DAM Group is specialized in instrumentation and software, electronics, automation and mechanical engineering. Basically, test benches are the core business of the French group. They are been recently involved in the development and production of […]

If you say ‘DAM’, we reply ‘hydrogen’ (Do you remember the agreement between Volvo and Daimler?). Why? You must know that DAM Group is specialized in instrumentation and software, electronics, automation and mechanical engineering. Basically, test benches are the core business of the French group. They are been recently involved in the development and production of a universal Cell Voltage Monitor (CVM) for fuel cell.

DAM and the ‘H2 way’ to clean mobility

We have written several times about hydrogen(i.e. concerning MTU), which finally appears to us in the launch pad. Blue or brown hydrogen can be applied quickly, but green hydrogen and fuel cells are the medium-long term target (do you agree, Nuvera, isn’t?). A supply chain that requires the contribution of different actors. This is what they tell us from their headquarters in Villeurbanne, in the Lyon metropolitan area.

Clear ideas for a clear project

“With 35 years of experience in the design and manufacture of test benches and complex systems, DAM Group sets out to conquer the hydrogen market with one main objective: the industrialization and acceleration of the adoption of competitive and universal hydrogen systems to benefit the energy transition for the transport sector. The search for funding has been a crucial step in the development of the product. After being supported and accredited by CARA, the competitiveness hub and Cluster Automobile of the Auvergne Rhône Alpes region, it was finally from the ADEME that DAM Group obtained significant funding for the implementation of the project.

CVM: Cell Voltage Monitor

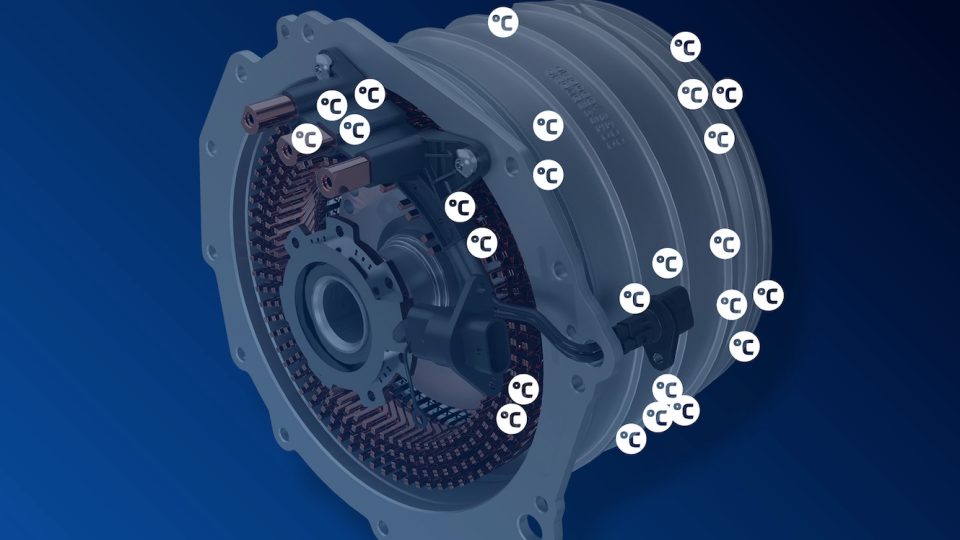

With the aim of providing state-of-the-art solutions to its customers, this funding will enable DAM Group to continue its efforts to develop a Cell Voltage Monitor (CVM), a universal connector that enables the monitoring and diagnosis of the bipolar plates that make up the stack.A first series will be developed for production benches and, in a second stage, production will be aimed at manufacturers’ all series vehicles.

Embedded regardless of the stack mounted in the vehicle, this CVM is described as universal and meets a wide range of needs.

The main objectives set by management are: Making a reliable and innovative product that meets current and future needs; The construction of a production line within 1 to 2 years; Production of more than 200,000/years parts within 10 years.

A dialogue among many players

This project is the result of numerous exchanges between customers, partners and other players in the sector (Hydrogen Europe, AFHYPAC) involved in these issues of standardization and cost reduction and is part of the development of hydrogen technologies already well established (sealing test of plates and stacks, packaging and test end of stack line, test station of high pressure lines). This development marks an important milestone for the Group, which for the past three months has had the opportunity to invest in the creation of “mass produced products” thanks in particular to the ordering of a By Pass valve for stack pack for a major player in the hydrogen sector.”