IMI VIVO Electrolyser in UK

IMI VIVO Electrolyser Powers South West’s First Hydrogen Production and Storage Facility

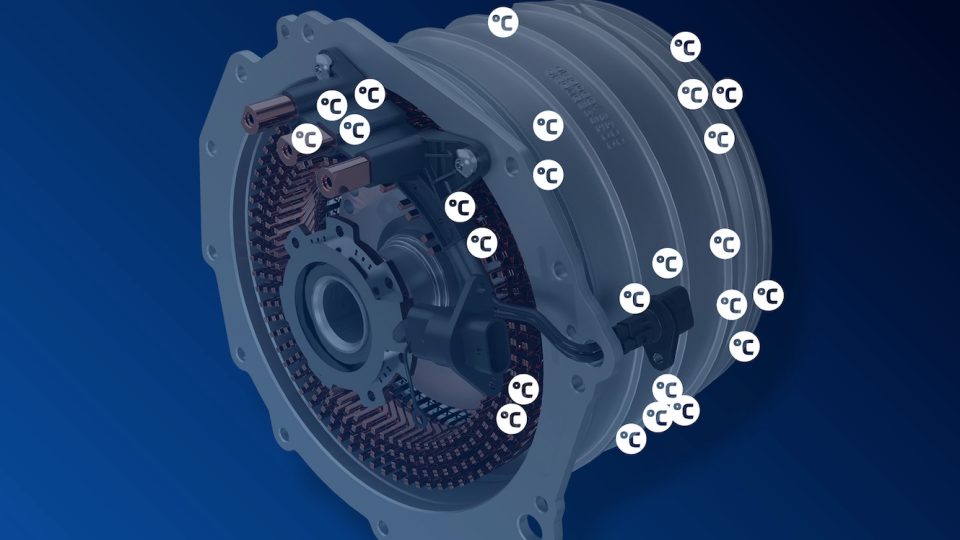

With the VIVO Electrolyser we once again talk about IMI and hydrogen. IMI VIVO, as a subsidiary of IMI Critical Engineering, played a crucial role in supporting the IAAPS (Institute for Advanced Automotive Propulsion Systems) in establishing the first green hydrogen production and storage facility in South West England. The installation of a new polymer electrolyte membrane (PEM) electrolyser is a significant step towards advancing research and innovation in the field of advanced propulsion. IMI VIVO Electrolyser was delivered in July 2023.

IMI VIVO, from IMI Critical Engineering, provides electrolyser

This project has the potential to drive advancements in the field of green propulsion and help address the global challenges of climate change and energy transition. It may also pave the way for further research and applications of hydrogen as a clean energy source in various industries and sectors. Research and innovation is carried out at its state-of-the-art, 11,300 sqm facility at the Bristol & Bath Science Park, which features a large solar array to power the electrolyser plant and produce green hydrogen. The plant and respective storage will be sized to allow the operation of a 400kW propulsion research facility. By producing green hydrogen through this process, the Institute for Advanced Automotive Propulsion Systems (IAAPS) has reduced its reliance on grey hydrogen for research purposes. Grey hydrogen is produced from natural gas through a process called steam methane reforming, which releases carbon dioxide emissions. In contrast, green hydrogen is produced through water electrolysis using renewable energy sources, resulting in zero carbon emissions during the production process. With the new H2 research capabilities made possible by the IMI VIVO Electrolyser, the IAAPS is now equipped to conduct research and development in the field of hydrogen technology. Additionally, the establishment of the regional H2 and Sustainable Transport Acceleration Hub in the South West aims to stimulate green growth in the region.

Quoting IAAPS and IMO VIVO

“This is an important development for IAAPS as we assume a pioneering role in the hydrogen landscape. With efforts to decarbonise the transport sector gathering pace, it is evident that there is a critical requirement for R&I in H2 propulsion. Our new green hydrogen facility allows us to meet this need and provide vital H2 research capabilities,” says Professor Rob Oliver, Engineering Director, IAAPS.

“The research into hydrogen technology conducted on site will assist industry in the development of new, sustainable propulsion technologies that are fundamental to achieving clean mobility and meeting net zero targets. We are delighted to establish this new, industry-leading facility at IAAPS, which also marks a significant investment in the national green hydrogen economy. We are thankful for IMI VIVO’s support in specifying, supplying and installing this exciting technology.”

“As well as being a cornerstone to IAAPS’ expansion and a major evolution in its remit and portfolio, the IMI VIVO Electrolyser has proven crucial to IAAPS solidifying its reputation as a leading adopter and supplier of sustainable solutions,” notes Jackie Hu, Divisional Managing Director at IMI Critical Engineering. “It is clear that IAAPS has great plans for both the electrolyser and its wider decarbonisation efforts, and we have been happy to help drive greener technologies and practices in the South West of England.”