Kreisel and John Deere Electronics @ ACT Expo

At ACT Expo 2025 Kreisel exhibited together with John Deere Electronics

The most prominent exhibitions, the real to-be places, reflect echo for weeks, sometimes months. This was the case at ACT Expo, where John Deere Electronics exhibited together with Kreisel. Yes, it’s the same Austrian company that we met at bauma Munich on the John Deere Power Systems booth.

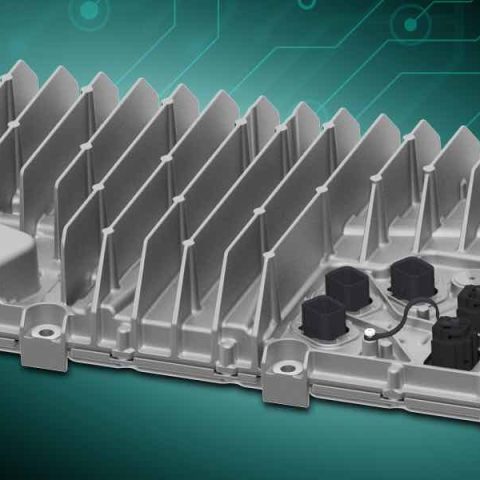

John Deere Electronics unveiled at ACT Expo its Vision Processing Unit

This is exactly how synergies work: focus on market targets, end-user demands, develop technologies that are sometimes mutually interchangeable, with the awareness that they must then be tailored to specific applications. So, if in Munich Kreisel went hand in hand with John Deeer Power Systems, at ACT Expo, the showcase of sustainability in US freight transportation vehicles, the partner was John Deere Electronics. The module, designed for rugged environments and advanced Computer Vision Machine Learning (CVML) applications, is now available to OEMs across various industries. This device, previously exclusive to John Deere precision agriculture solutions, offers a high GPU- and high CPU-capable platform, enabling OEMs to integrate sophisticated vision-based automation into their own products. It features compact, powerful technology, chosen for its performance in GPU and CPU per watt and its efficient power dissipation, which is essential for demanding processing tasks. The module is also equipped with 12 ports for camera integration to enable comprehensive visual data capture. It is engineered to withstand harsh operating conditions: boasting an IP67 rating for full submersion in water and an operational temperature range of -25°C to 50°C. It seamlessly interfaces with vehicles and machinery through industry-standard communication protocols, including CAN and Ethernet.

“We’re proud to offer OEMs a vision processing unit that truly stands apart. We’ve engineered this module to perform in the harshest environments, focusing on robust thermal and vibration performance. Unlike others on the market, we’ve achieved this without liquid cooling or internal fans, relying on innovative air cooling and a rugged IP67-rated design,” said Nicholas Weisbeck, electronics systems module manager at John Deere. “The result is a highly reliable platform for cutting-edge CVML applications, enabling OEMs to bring advanced processing capabilities and greater autonomy to their customers while addressing the growing challenge of labor availability.”

The VPU enables OEMs to integrate the proven reliability and high performance of John Deere advanced electronics into a wide range of innovative solutions. Designed for demanding environments, this module excels in diverse applications that extend far beyond traditional agricultural uses. The 12 camera ports offer comprehensive visual data capture, facilitating such applications as:

- Enhanced safety and operational efficiency: Advanced vision systems for obstacle avoidance and improved situational awareness across various vehicle and machinery types.

- Intelligent automation and control: Autonomous navigation, advanced robotics, and real-time image and video processing, along with AI-driven quality control and inspection across a broad spectrum of industrial sectors.

And what about Kreisel?

The modularity of the Kreisel high-performance batteries allows to individually place batteries from the same power level in the usually very limited installation space and is suitable for any kind of application, off-highway and on-road. They are also conscious of this in Austria. “With our future-oriented Dynamic Performance Management enabled by patented cell immersion cooling technology and advanced software, Kreisel’s batteries will continue to play a key role in increasing the performance, lifetime, and safety of EV applications and support OEMs & Tier 1’s in achieving their goals,” stated Markus Kreisel, Co-founder and member of the management board at Kreisel. “The Kreisel high-tech battery solutions enable manufacturers to shorten their development time for new vehicle projects and meet their needs for state-of-the-art battery technology.”

A significant step forward in battery technology is announced by the Kreisel co-founder. “A new battery pack designed for seamless integration with off-highway machinery – targeted for production in 2026 – feature a flexible, modular architecture for best possible battery placement,” added Markus Kreisel.