MAN ES and the large-scale Porthos project

Porthos project set to capture and permanently store 2.5 million tons of CO2 emissions annually using MAN compressor technology

MAN Energy Solutions has won the contract for the delivery of three integrally-geared compressor trains (IGC) to the first large-scale carbon capture and storage (CCS) project in the Netherlands. The Port of Rotterdam Authority, Energie Beheer Nederland B.V. (EBN) and N.V. Nederlandse Gasunie are jointly conducting the ‘Porthos’ (Port of Rotterdam CO₂ Transport Hub and Offshore Storage) project, recognized by the European Union as a Project of Common Interest (PCI).

Porthos aims to store 2.5 million tons of CO2 annually in exhausted natural-gas reservoirs under the North Sea. The CO2 will be sourced from various companies in the Rotterdam port area – a region accounting for over 16% of Dutch CO2 emissions. The carbon will be compressed by MAN Energy Solutions’ technology, and then transported and injected into a sealed reservoir of porous sandstone over 3 km beneath the North Sea. Over a 15-year timeline, a total of 37 million tons of CO2 will be permanently stored in this way.

Uwe Lauber, CEO of MAN Energy Solutions, said: “We are extremely proud to be part of this pioneering project aimed at reducing CO2 emissions. Not only will Porthos play a vital role in propelling the Netherlands toward achieving net-zero emissions, the project is also innovative in its approach that aims at establishing a CO2transport and storage infrastructure serving multiple companies. Such game-changing initiatives are crucial in advancing CCS efforts and effectively reducing emissions that are hard to abate.”

Porthos has signed agreements with Air Liquide, Air Products, ExxonMobil and Shell and will capture their respective CO2 emissions, feeding them into a common pipeline that will run some 30 kilometers through Rotterdam’s port area.

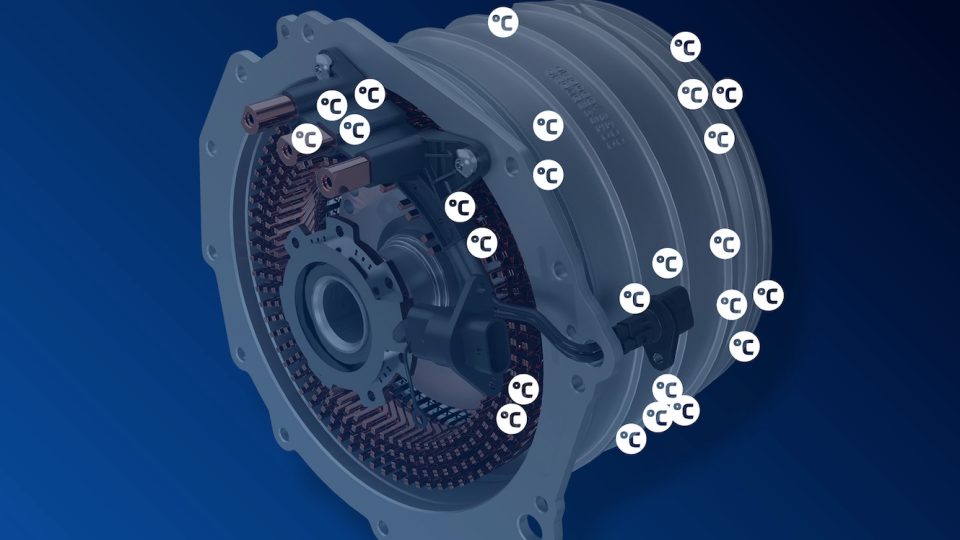

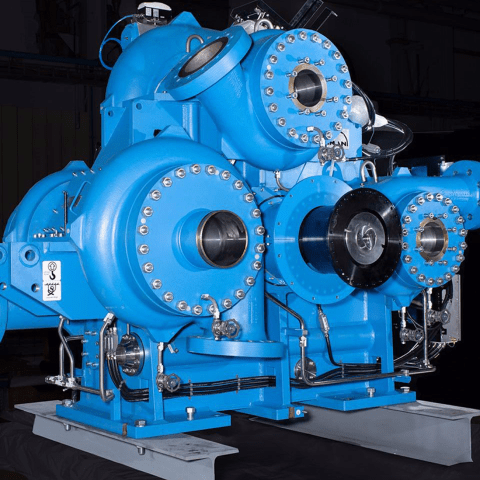

MAN Energy Solutions’ scope of work covers the delivery of three RG 28-6 type compressor trains with an order for two additional units intended at a later stage. The compressor trains will be located at a station on Maasvlakte, the man-made, western extension to Europoort. There, the CO2 will be compressed to different discharge pressure levels – to a maximum of 180 bar – with each compressor handling up to 250 tons of CO2 per hour. Part of the scope includes a dynamic process simulation, which will allow the compressor system to be operated to its fullest potential in terms of process efficiency.

From the compressor station, a 22 km pipeline will transport the CO2 in gaseous form to the P18-A platform in the North Sea where the CO2 will be pumped into the exhausted P18 gas fields 3,200 to 3,500 m below the seafloor, which have a CO2 storage capacity of around 37 million tons. The system is expected to be operational by 2026.

Marco Ernst, Head of Sales & Project Management CCS at MAN Energy Solutions, said: “This major order proves once again that MAN Energy Solutions is consolidating its technology leadership position as a provider of state-of-the-art CO2 compression solutions. Our RG compressor design with integrated gearbox and individual stages operating at their own optimized speeds is ideal for CO2 compression with very high-pressure ratios.”