At IAA cellcentric unveils the NextGen fuel cell system for heavy-duty transportation

As a sustainable solution for CO2-neutral mobility in global road transportation, cellcentric presented a virtual model of its NextGen fuel-cell system for long-haul heavy-duty transport for the first time at the IAA Transportation in Hanover.

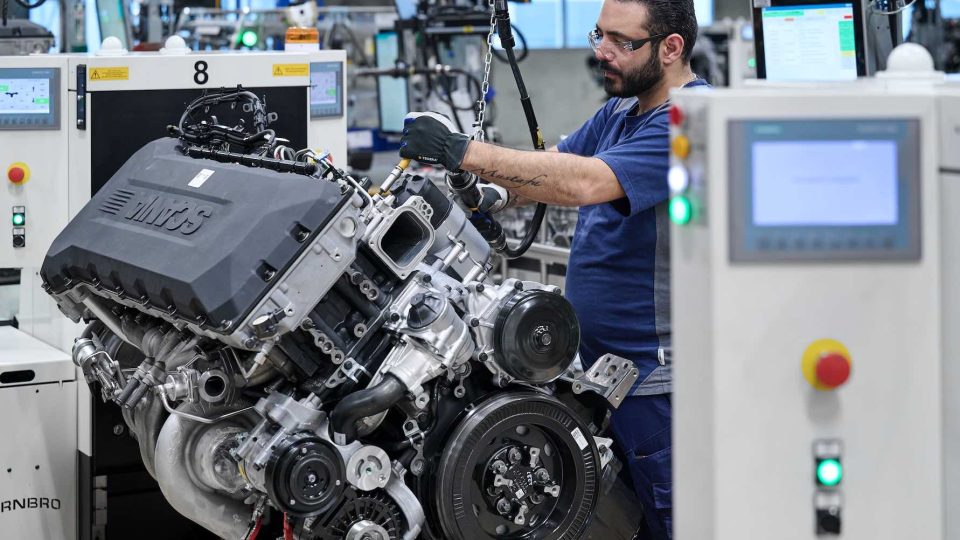

As a sustainable solution for CO2-neutral mobility in global road transportation, cellcentric presented a virtual model of its NextGen fuel-cell system for long-haul heavy-duty transport for the first time at the IAA Transportation in Hanover. This virtual model provides a preview of the dimensions and design of the game changing new generation of fuel-cell systems. With a total weight of less than 400 kg, this new system presented at IAA by cellcentric is designed for conventional 13-liter diesel engine compartments. The new single-packaging fuel-cell system will combine high efficiency and performance with market leading TCO. In addition, the system is characterized by higher operating temperatures and lower cooling requirements.

Below are the technical features of the NextGen fuel cell system:

Target performance figures (vs. benchmark fuel cell system BZA150)

· Single system package

· Up to 375 kW (more than 500 horsepower) continuous net power

· 20% less fuel consumption

· 40% reduction of waste heat at 300 kW net power

· 40% more power density

· 40% reduction of complexity

Current BZA150 production of fuel cell systems in Esslingen (Germany) is a milestone towards reaching CO2-neutral mobility in the heavy-duty transport of tomorrow, utilizing highly efficient industrial-grade production processes. Furthermore, the industrialized pilot production in Esslingen marks another step towards the arrival of Europe’s largest fuel cell production facility – the new KLIMA|WERK factory in Weilheim – which is planned to open towards the end of the decade.

Read also: Fuel cell systems, cellcentric to begin pilot production