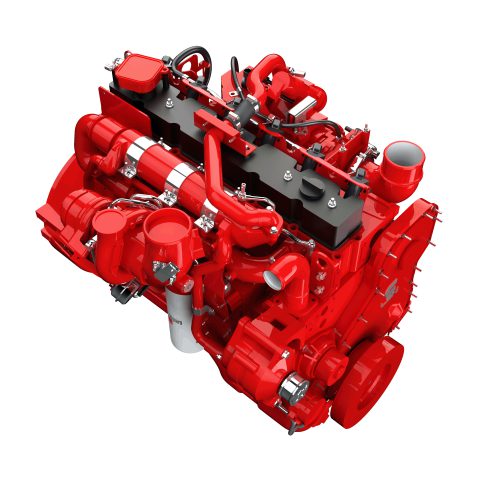

Cummins: first natural gas engine produced in Darlington plant

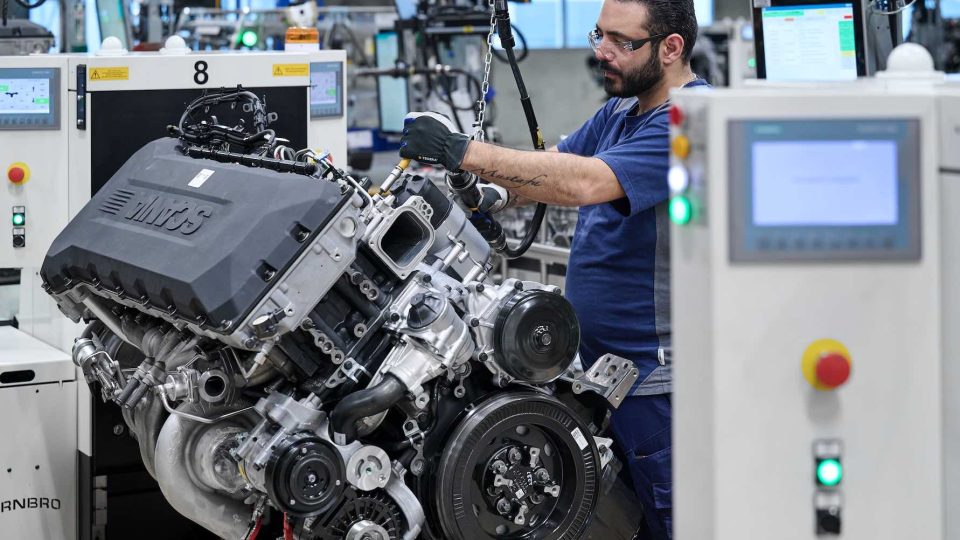

Cummins Darlington Engine Plant has celebrated the production of its first L9N engine, the first natural gas engine produced at the UK plant in its 58-year history. The 8.9 litre can operate on compressed or liquified natural gas as well as renewable natural gas, which significantly reduces well-to-wheels carbon emissions.

Cummins Darlington Engine Plant has celebrated the production of its first L9N engine, the first natural gas engine produced at the UK plant in its 58-year history. Produced alongside 72,000 diesel engines a year in Darlington, the 8.9 litre L9N (280 – 320hp) combines an ultra-low emissions profile for CO₂, NOx and particulate matter, with diesel-like performance and reliability. The L9N can operate on compressed or liquified natural gas as well as renewable natural gas, which significantly reduces well-to-wheels carbon emissions.

Ashley Watton – Director, Bus Business Europe at Cummins, said: “Cummins’ natural gas engines are a practical, readily available technology for customers seeking quiet, fuel efficient, ultra-low emissions power for urban transportation. Producing these engines locally for our European truck and bus OEM customers improves logistics and responsiveness as well as the all-round sustainability of this business.”

Designed to meet Euro 6E emissions regulations, the L9N is in high demand from the European bus market, particularly in cities with low emission zones. It is currently helping to transport passengers on city bus routes throughout Azerbaijan, Estonia, Poland, Spain, and Turkey.

Cummins transferred production of the L9N from its Rocky Mount Engine Plant in North Carolina, USA, to provide its Europe-based L9N customers with in-region supply. This has reduced supply chain complexity and supports more sustainable operations by shortening shipping distances and times. The move was completed in just six months and saw a significant investment in the Darlington plant.

The L9N shares many components and parts with Cummins L Series diesel engines, inheriting not only their renowned simplicity but also allowing Cummins to build it on the same assembly line as its diesel engines.

“Cummins global manufacturing network means we build engines where our customers need them. Bringing L9N production to our Darlington Engine Plant will ensure we continue to deliver a high level of service to our key customers at a time of increased demand for our products, particularly in Europe. It also broadens our capabilities – producing spark ignited engines for the first time in Darlington positions us well for other low and zero carbon fuels in the future. This is enormously positive for the plant, our people, and our local economy,” Watton continued.

The L9N is one of Cummins’ many ultra-low or zero emission power solutions that are either in development or powering vehicles and equipment right now. Cummins is leveraging its experience in producing natural gas engines for other spark-ignited technologies including hydrogen internal combustion engines, which use zero-carbon hydrogen fuel.

Cummins’ power portfolio includes ultra-clean diesel, natural gas, hydrogen fuel cells and battery systems – all contributing towards the achievement of Cummins’ Destination Zero strategy to reduce emissions from the world’s hardest working sectors.