FPT Industrial at ACT Expo with electric axles and XC13 engine

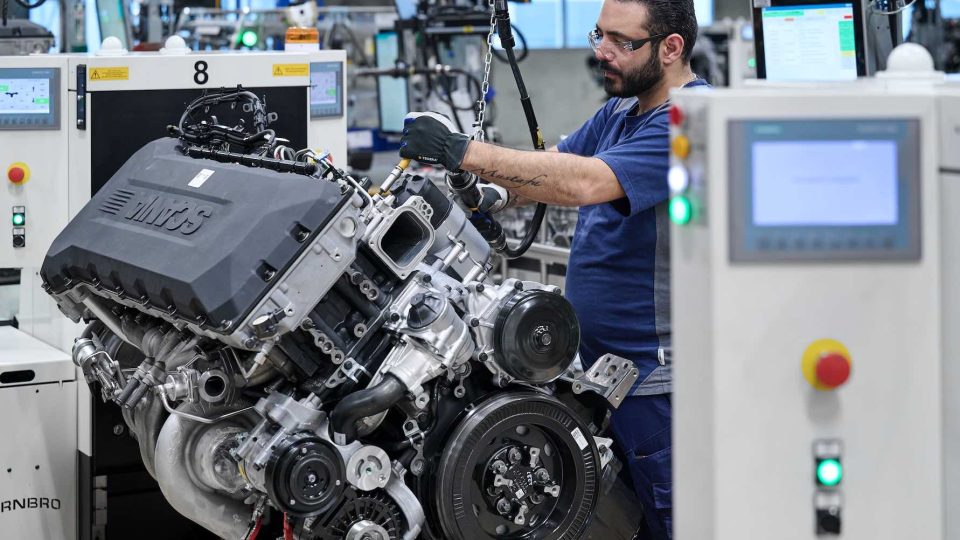

FPT Industrial is participating in ACT Expo 2024, underway in Las Vegas, with its electric axles, produced in the ePowertrain plant, and with the multi-fuel XC13 engine that we had already seen at Agritechnica.

FPT Industrial is exhibiting at ACT Expo 2024, the world’s largest advanced commercial vehicle technology show, underway in Las Vegas, from May 20 to 23, 2024.

At its stand FPT is putting into practice its flexible approach to the energy transition by showcasing both ePowertrain solutions, and multifuel ICE powertrains. In keeping with its 360-degree approach towards carbon neutrality, FPT Industrial will offset the emissions generated by its stand at ACT Expo, as it had already done on the occasion of Agritechnica. All the factors and actions involved in the stand’s construction, dismantling, power, and transportation will be taken into consideration, and the total carbon footprint will be offset through the purchase of certified carbon credits.

Visitors have the chance to see up close the 6×4 eAxle eAX375, a first for the North American market, and the first model of FPT Industrial’s second generation eAxles; the eAX840-R, the first HDT eAxle on the market; and the LCV Central Drive eCD140; as well as the new XC13, FPT Industrial’s first single-base multi-fuel engine, shown with its three different engine heads for diesel, natural gas and hydrogen versions.

“By exhibiting at ACT Expo 2024, we are showing the vehicle industry our multifaceted capability of delivering efficient, viable and tested solutions, whatever the technology and the fuel,” says Daniele Pozzo, Head of Marketing & Product Portfolio at FPT Industrial. “This event presents a significant opportunity to connect with key stakeholders, explore new business opportunities, and showcase our commitment to sustainable transportation solutions.”

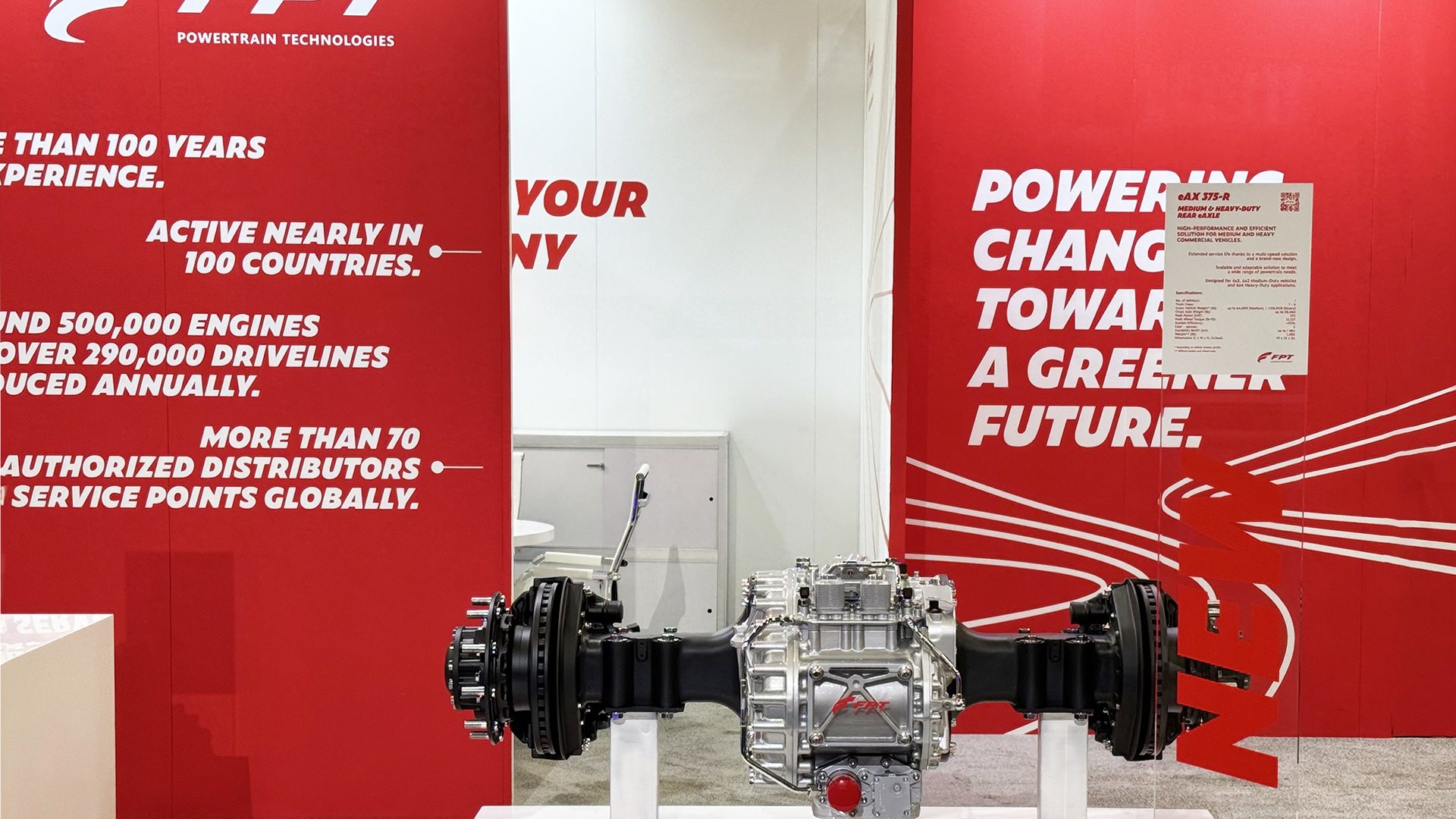

eAX375-R, the e-axle for medium- and heavy-duty

Making its debut in North America and marking the birth of the second generation of FPT Industrial eAxles, the eAX375-R integrated electric axle is suitable for medium-duty 4×2 vehicles of up to 29 tons GVW, and heavy-duty 6×4 vehicles of up to 49 tons GCVW. Thanks to multi-speed gearing, the eAX375-R delivers high performance and outstanding efficiency.

The design developed by FPT Industrial’s team, such as the bolted wheel end, allows the electric axle to be scalable and extremely adaptable to meet different powertrain requirements. Up to 30,000 Nm / 22,000 lb-ft torque at the wheels, and service life of up to a million miles (depending on customer mission), it ensures sustainability and delivers uptime performance.

eAX840-R, single-speed dual-motor electric axle

FPT Industrial introduced this axle co-developed with input from Nikola for the Nikola Tre Class 8 truck in the United States. As the first HDT eAxle on the market, it is designed for heavy vehicles, with multiple transmission ratios available. The eAX840-R is a groundbreaking solution in the electric truck market, offering a unique combination of efficiency, performance, and ease of integration. Its single-speed design eliminates the need for a transmission control unit (TCU), simplifying the overall system and reducing development time. This enabled FPT Industrial to bring the eAX840-R to market in just two years from the concept stage.

eCD140 for LCVs

FPT Industrial’s Central Drive – eCD140 for Light Commercial applications is a compact and complete solution for incorporating electric drive systems into existing conventional vehicles of up to 8 tonnes GVW. FPT Industrial’s team has designed a lean, integrated central drive system which guarantees easy implementation into existing platforms, and optimized residual space for installation of battery packs.

For rear-wheel-drive applications, as with all FPT Industrial products, the eCD140 is extremely durable, efficient, and reliable (up to 350,000 km / 220,000 mi, with lifetime oil fill depending on customer mission).

FPT Industrial, the XC13 multi-fuel engine also at ACT Expo

Unveiled at the last IAA show and installed on new IVECO S-Way MY24, the XC13 is FPT Industrial’s first single-base multi-fuel engine. From diesel and natural gas (including biomethane) to hydrogen and renewable fuels, this base engine has been designed and engineered with multiple versions to allow maximum standardization of components, and minimum impact for facilitated installation on the vehicle. The new engine is positioned as a primary contributor to achieving the 2025 fleet-wide CO2 emissions target, the group’s most significant decarbonization program. A major step on the ICE decarbonization path, the XC13 guarantees reduced TCO together with best-in-class performance and braking power, thanks to the new valvetrain system, as well as significant weight reductions thanks to a new lighter cylinder block and cylinder head (-10% for both applications).

The diesel version delivers up to 600 hp and 2850 Nm/2150 lb-ft, resulting in +14% torque and +5% power compared to the previous C13. The natural gas version delivers up to 520 hp and 2500 Nm / 1840 lb-ft, representing +25% torque and +13% power compared to the previous C13 NG. CO2 emissions reductions of 9% for the diesel unit and 10% for the natural gas model have been achieved, but a full 100% reduction in net CO2 emissions is achievable when fueled by bio-methane. Just a week after launch, a CO2-free hydrogen-powered version of the LeitWolf snow groomer, boasting 460 hp and 2,000 Nm / 1475 lb-ft torque, debuted in Vipiteno, Italy, in collaboration with Prinoth. The off-road XC13 hydrogen engine debuted at Agritechnica 2023, offering 520 hp, crucial for accelerating industrial decarbonization efforts.