Cummins’ synoptic view of the onroad world

At IAA, we talked about onroad with Felipe Rocha - General Manager, On-Highway, Europe, Cummins, and Brian Wilson - General Manager, eMobility, Accelera by Cummins

Cummins has also achieved a clear vision in the onroad environment, where it is maximizing group synergies. In particular the one with Meritor. We talked about this evolution at the IAA with Felipe Rocha – General Manager, On-Highway, Europe, Cummins, and Brian Wilson – General Manager, eMobility, Accelera by Cummins.

A complete driveline for onroad applications

The more expertise and capabilities we develop or acquire, the better we can tailor our solutions—almost like a secret recipe. We aim to be the best powertrain partner for our customers – the vehicle OEMs. Now with full powertrain capability, Cummins and Accelera by Cummins can optimise engines, transmissions, axles, e-axles, motors, and inverters to enhance overall system efficiency. While it’s hard to pinpoint one component, developing much more of the powertrain allows us to optimize the full system for our customers, based on their specific needs. If you compare our presence today with 2022, you’ll see all these components displayed in advanced diesel, hybrid, BEV and hydrogen configurations. It clearly shows how engines, transmissions, and e-axles can be integrated to enhance fuel economy.

It’s a complex time with emissions regulations. Can you speak to that?

Yes, this is indeed a challenging time, and these regulations are driving a wide range of technologies like battery electric, fuel cell, and hybridization. Our goal is to ensure the market can adopt the right technology at the right time. To do this, we’ve brought together a broader range of capabilities, experience, and technologies to support OEMs and end users in reaching their sustainability targets. Our approach allows us to consult with them to determine the best solution for their specific use case and ensure technology timing aligns with their sustainability goals and wider infrastructure availability. Because we offer a wide array of solutions, we don’t need to push any particular technology. Instead, we partner with OEMs and end users, ensuring they’re making the right choices for their operational needs.

Could you elaborate on the value of being a system integrator?

Absolutely. There’s significant value in being a system integrator, especially in areas like batteries and fuel cells. Our knowledge, gained from integrating engines over the years, translates to these newer technologies. With over 100 years of experience in understanding what trucks need to do daily, our diesel engine expertise helps us design better systems on the battery electric side. We know the operations, duty cycles, and expectations of truck users, which informs our design process.

What can you tell us about the X10 Euro 7 and X15 hydrogen engines?

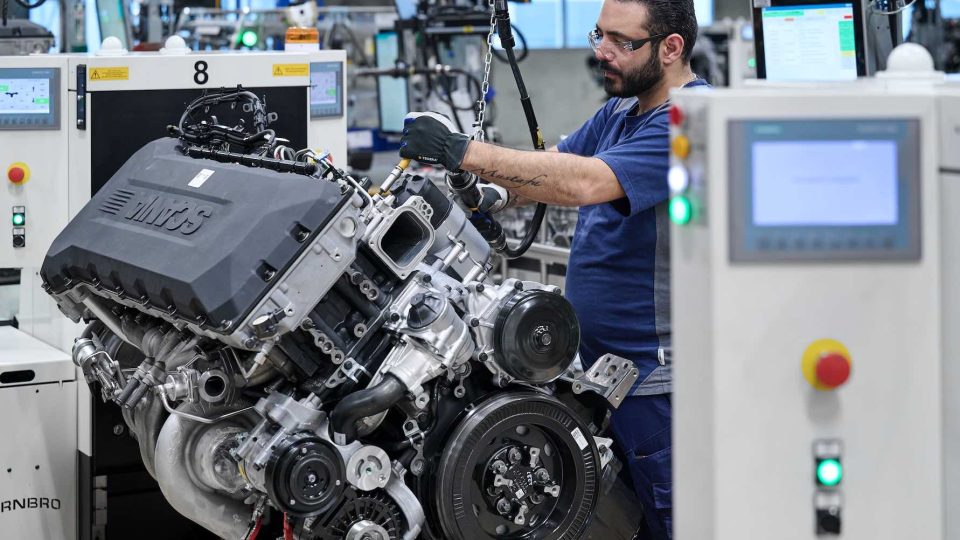

There are key differences at Euro 7 in both in the emission limits and in the cycles, compared to Euro VI. Our new engine designs have evolved from previous versions—most notably, we’ve shifted to double overhead camshafts. With our acquisition of Jacobs Vehicle Systems, we’ve integrated a highly capable valvetrain system that allows these engines to meet stringent cycle requirements without compromising fuel efficiency.

The X10 advanced diesel engine on display at IAA is not only lighter, but also more fuel-efficient. In terms of power density—power generated per kilogram—it’s best in class, with up to 335 kW / 450 hp and 2300 Nm peak torque. We’ve worked on eliminating parasitic losses and used advanced materials to achieve these improvements. The engine is likely to be 200 kg lighter than the average in its class, which contributes to better fuel economy and payload.

CUMMINS AND ONROAD ACCORDING TO JENNIFER RUMSEY

Cummins ’ onroad powertrain display also features hydrogen internal combustion engine technology from its X15H – part of the company’s 15-litre platform. With power ratings from 298-395 kW (400-530 hp) and peak torque of 2600 Nm, the X15H offers an operating range comparable to current diesel engines, ideal for heavier-duty or longer-range applications. The engine is displayed alongside Cummins’ production-ready 700-bar hydrogen fuel delivery system, with Type IV on-vehicle storage vessels from its NPROXX joint venture.

What about alternative fuels?

We continue to develop and invest in our internal combustion engine technologies, including alternative fuel capability. At this year’s IAA we displayed the Cummins HELM™ fuel agnostic platforms also for onroad applications, which feature a series of engine versions that are derived from a common base. Below the head gasket of each engine are largely similar components and above the head gasket will have different components for different fuel types – either advanced diesel, natural gas or zero-carbon hydrogen. Each engine version will operate using a different, single fuel.

Natural gas is an interesting option, especially renewable natural gas. It’s more common in North America than in Europe at the moment, with cost and regulation playing a big role in its adoption. The X15N recently launched in North America is designed to meet the needs of heavy-duty fleets and we’re seeing new markets opening up to the idea of switching to natural gas.

Hydrogen is an additional option, and the X15H hydrogen combustion engine is an example of how zero-carbon hydrogen fuel can be used in a practical, familiar way. The challenge for hydrogen is infrastructure, and adoption largely depends on regional incentives. Cummins is making progress in this technology though, and the direct injection X15H is targeted for production at the end of this decade. A small batch of B6.7 hydrogen internal combustion engines have already been manufactured in India for key customer and partner Tata Motors.