SEAT and ADLER Group. Car passengers factories against Coronavirus

SEAT and ADLER Group, two sides of the same coin. The medal is that of the automotive world that will reconvert production to face the COVID-19 emergency. SEAT Martorell facilities Let’s begin with SEAT, that “starts the production of emergency ventilators at its Martorell facilities to contribute to the crisis caused by COVID-19. The device […]

SEAT and ADLER Group, two sides of the same coin. The medal is that of the automotive world that will reconvert production to face the COVID-19 emergency.

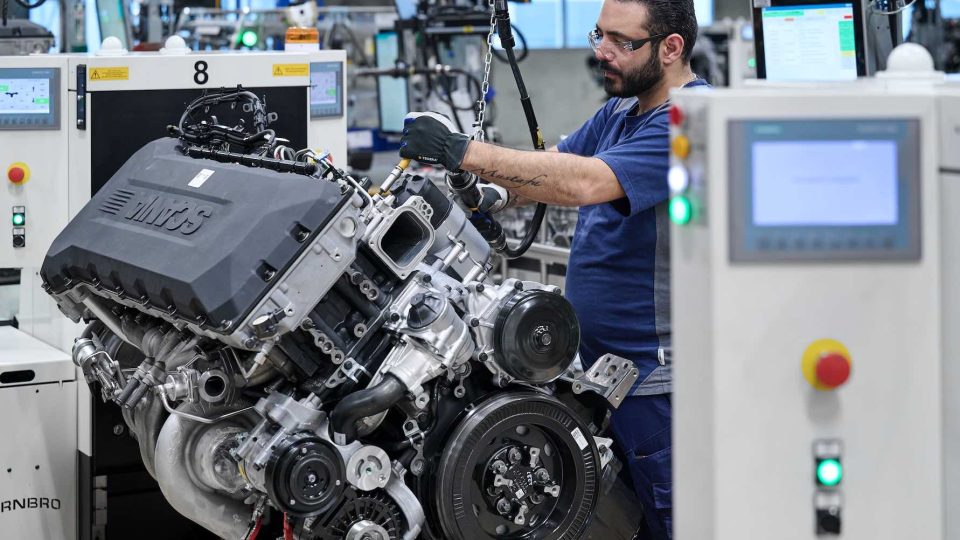

SEAT Martorell facilities

Let’s begin with SEAT, that “starts the production of emergency ventilators at its Martorell facilities to contribute to the crisis caused by COVID-19. The device has been authorized by the Spanish Agency of Medicine for clinic investigation and the daily production volume will be constantly adjusted with the authorities according to demand to avoid unnecessary stocks. The company will work to reach a production volume of 300 emergency ventilators a day at the SEAT Leon assembly line. The device, called OxyGEN, was free hardware designed by the company Protofy.xyz and under the medical coordination of doctors Dr. Manel Puig Domingo (Germans Trias y Pujol Investigation Institute), Dr. Oriol Estrada (Hospital Germans Trias i Pujol), y Dr. Josep María Nicolás (Hospital Clínic), in a collaborative work against the clock for the past two weeks to make this project a reality.

In the industrialization process, lead by SEAT, different partners have collaborated. This emergency ventilator is being produced on the SEAT Leon assembly line at SEAT’s facilities and has an adapted windscreen wiper motor. Each device has more than 80 electronic and mechanical components and passes a thorough quality control with ultraviolet light sterilisation.”

ADLER Group manufactures masks

Switching from the carmakers to the components specialist, the sense doesn’t change. “ADLER Group will manufacture masks and other personal protective equipment through its Italian subsidiaries Mectex in Erba (close to Milan) and Tecnofibre in Morra De Sanctis (not faraway from Naples) to address the COVID-19 health emergency. Support from the Scudieri Foundation (editor’s note: the Scudieri family owns ADLER Group) to the Campania Region in fundraising and in finding products and technologies for prevention. A specific model of mask was designed, the Italia model, which accomplishes the legal requirements and has the advantage of being completely recyclable in the production of textile components for the automotive sector, once the life cycle of the product (10 washes) has been completed. The proceeds from the sale of the masks will be partly donated to the Scudieri Foundation, to be destined to Italian structures that are facing the health emergency.”