Bonfiglioli @ Agritechnica 2025

Bonfiglioli attended Agritechnica 2025. On display solutions for agricultural robots and machinery – particularly for sprayers and feed mixers – while also highlighting a key technological evolution: the electrification of small autonomous agricultural vehicles and attachment drives

Bonfiglioli attended Agritechnica 2025 providing expertise for its usual target, as sprayers and feed mixers, and also turning to solutions for agricultural robots. Under the lens the electrification of small autonomous agricultural vehicles and attachment drives.

Agritechnica is the place where Bonfiglioli emphasized agri-robots

Agri-robots are transforming modern farming by automating key operations such as planting, harvesting and crop monitoring. These machines enhance productivity, reduce resource consumption and support more sustainable agricultural practices. With a range of reliable products for wheeled and tracked AGV robots, Bonfiglioli provides machine builders with high-performance drive solutions.

The Bonfiglioli portfolio ensures outstanding performance, delivering high torque in a compact design with minimal axial dimensions.

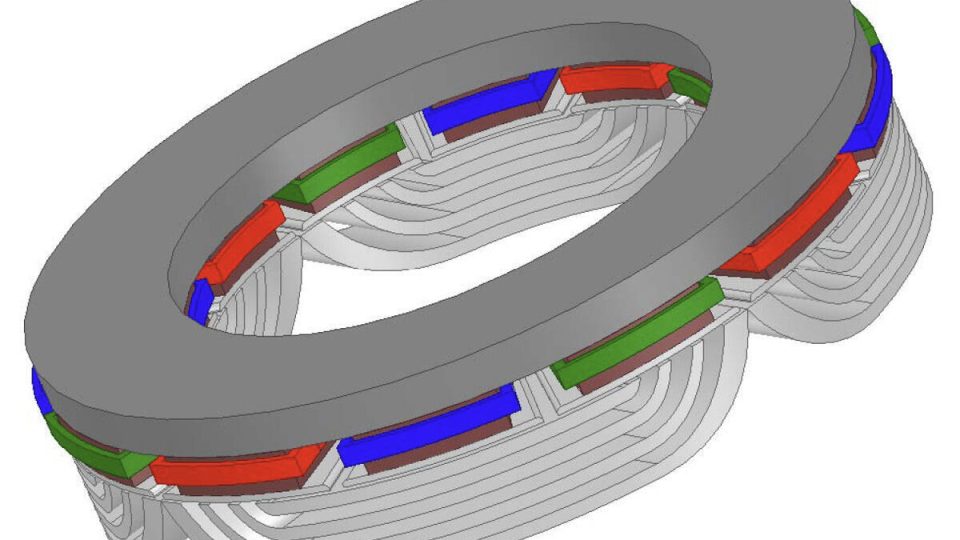

The electric drives feature a maintenance-free, space-saving electric motor offering dimensions comparable to hydraulic systems. For wheeled agri-robots Bonfiglioli offers a complete solution consisting of a planetary drive of the 600WE Series, a precision planetary gearbox of the MP Series and a BMD brushless servomotor for steering drives. This permanent magnet synchronous motor features extremely compact dimensions and high torque, meeting the most stringent demands for precision, dynamics and speed settings. Suitable for 48-400 Vdc batteries, it boasts a protection rating >IP65 and precision steering thanks to low backlash.

The solution proposed for tracked agri-robots includes a track drive of the 700CE Series, characterized by compact design and high torque, as well as integrated electromagnetic parking brake and speed and temperature sensors, and a BPM electric permanent magnet motor for pump drives. Specifically designed for mobile pump applications, it offers high protection degree – >IP65 – and cooling concept, as well as optional SAE flanges and EM failsafe parking brake.

For sprayers a wheel drive of the 600WT Series is showcased. The new drive unit features a spring-applied, hydraulically released integrated parking brake that ensures safety and reliability in all operating conditions. It includes a mechanical gear disengagement system for enhanced serviceability. With input speeds up to 4,000 rpm and gear ratios ranging from 22 to 53, the system delivers exceptional flexibility and performance. Additional options include customizable brake configurations and an integrated speed sensor for precise motion control. For feed mixer, Bonfiglioli delivers auger drives of the 700T Series. Characterized by a compact, rugged design, high torque and load capabilities, the series provides the safest, most effective solution for vertical and horizontal feed mixers. Its broad versatility is guaranteed by its different interfaces and by the two-shaft configuration for both in-line and multi-auger models.

Martin Haase and interview that you’ll be able to read on the first issue of 2026

Martin Haase introduces us to Bonfiglioli’s latest innovations in the field of agricultural mechanization. ”We have introduced a wheel drive that integrates a centralized tire inflation control system, allowing the user to monitor and adjust tire pressure based on terrain conditions and operational requirements. This system allows air to be inflated and deflated directly from the wheel without an external connection, but rather from the gearbox. Normally, an external connection to the wheel is required, which is connected at the front. This eliminates that obstacle, improves space efficiency, and increases maneuvering safety.”

To read the full interview, stay tuned for our upcoming January-February issue of POWERTRAIN International!

Dynamic tyre management

Bonfiglioli’s wheel drive comes with integrated Central Tyre Inflation System which allows the operator to monitor and adjust tyre pressure according to the soil condition and operation needs, while he’s driving and without leaving the cabin. Due to its features, such as automatic over-speed protection, multi-channel pressure control and integrated diagnostics alerts, CTIS improves better mobility through increased traction while driving off road, on sand and mud, and allows higher vehicle speeds and fuel saving during on-road transfer.

Moreover, it enhances performance because it eliminates tyre leak down. Indeed, seals and control hoses are isolated from tyres and not pressurized during normal operation or when parked. Finally, it allows continuous vehicle operation with less tyre wear.