BorgWarner cam phasers @ bauma and so on

The third chapter of the narrative from BorgWarner's stand at bauma focuses on cam phasers, with a brief mention of turbocharging, which we will cover in more detail soon

Our narrative on BorgWarner’s participation in bauma 2025 continues. This time, we focus on cam phasers, with a brief mention of turbochargers, which we will continue in the next and final chapter.

Starting with BorgWarner cam phasers

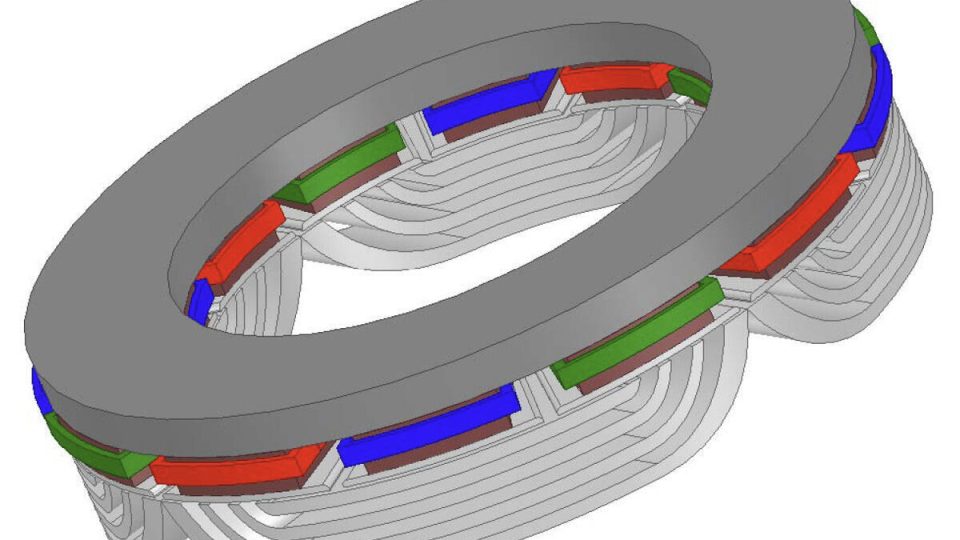

We are introduced to the topic by Alessandro Benedetti, Product Engineer, who has spent nearly two decades at BorgWarner, starting his journey within the Morse division, which traditionally focused on chain-driven timing systems—solutions more typical in passenger cars than in commercial vehicles, where gear-based systems are more common.

“In recent years, we’ve shifted focus and begun developing variable cam timing systems specifically for commercial vehicles,” Benedetti explains. “Today, we have two cam phasers in series production for this segment. One originates from the acquisition of the cam phasers that Mercedes-Benz used to produce in Berlin. We’ve since localized production to our Polish plant in Rzeszów, near Krakow. These phasers are used on Mercedes medium-duty trucks, with inline 4- and 6-cylinder engines of 5.1 and 7.7 liters.”

BorgWarner ’s other cam phaser for commercial vehicles was developed in-house and is now in use on Scania’s 5- and 6-cylinder engines—covering displacements of 10, 12, and 13 liters. “In heavy-duty applications, phasers play a key role in supporting aftertreatment,” Benedetti says. “They help accelerate exhaust system warm-up and maintain optimal temperature, which is crucial for emissions control. Additionally, they can be used in engine braking mode.”

About turbocharging

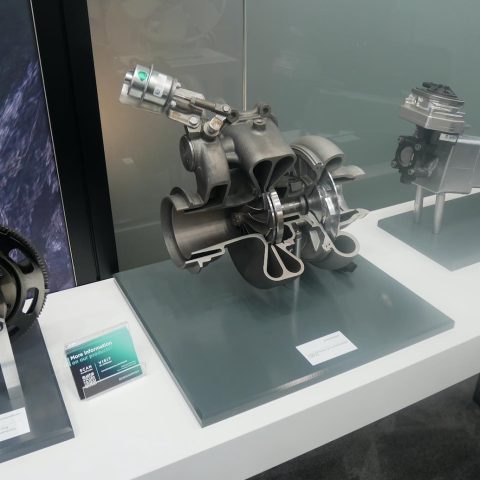

Turbocharging remains another major area of innovation for BorgWarner. The company has developed an e-turbo for the Porsche 911, equipped with a high-voltage electric motor positioned between the turbine and the compressor. “It boosts compressor speed to eliminate turbo lag,” says Benedetti. “And in a Formula 1-style configuration, it can harvest excess exhaust energy and redirect it as traction power in hybrid systems.”

Talking about the needs of the off-highway sector, particularly in construction equipment, Benedetti points out that the approach differs substantially from on-road applications. “Engine use is more moderate. You don’t need electronic control systems—pneumatic actuation is sufficient. There’s no requirement for wastegate or variable geometry turbos because these machines don’t experience rapid transients like road vehicles. What matters most is durability and robustness.”

Looking to the future, Benedetti acknowledges the growing pressure to evolve. “We made a conscious decision to stay in internal combustion until the very end—last one standing, if you will. But electrification in construction is moving fast. It’s driven by regulations and the push for zero-emission job sites. Electric motors offer performance advantages, especially in energy recovery. In mining, for example, heavy-duty vehicles often act both as motors and generators. Without electrification, you’d need bulky mechanical systems just to handle braking.”