EdiLog embraces sustainability with Twin Disc Pump Drive

With electric operation, EdiLog log stacker embraces modern technology and takes sustainability to a completely new level with Twin Disc’s AM365 Pump Drive

With electric operation, EdiLog log stacker embraces modern technology and takes sustainability to a completely new level with Twin Disc AM365 Pump Drive. Modern technology ensures reliability and reduces operating costs for a production-critical function, with the mission of operating around the clock, seven days a week. The approximate savings are around 5% by re-utilizing kinetic energy, 5% by reducing idling and 25% with a more efficient start and stop. The recorded results are a fuel saving of 28%, lower operating and maintenance costs, reduced CO2 emissions by 120 tons annually.

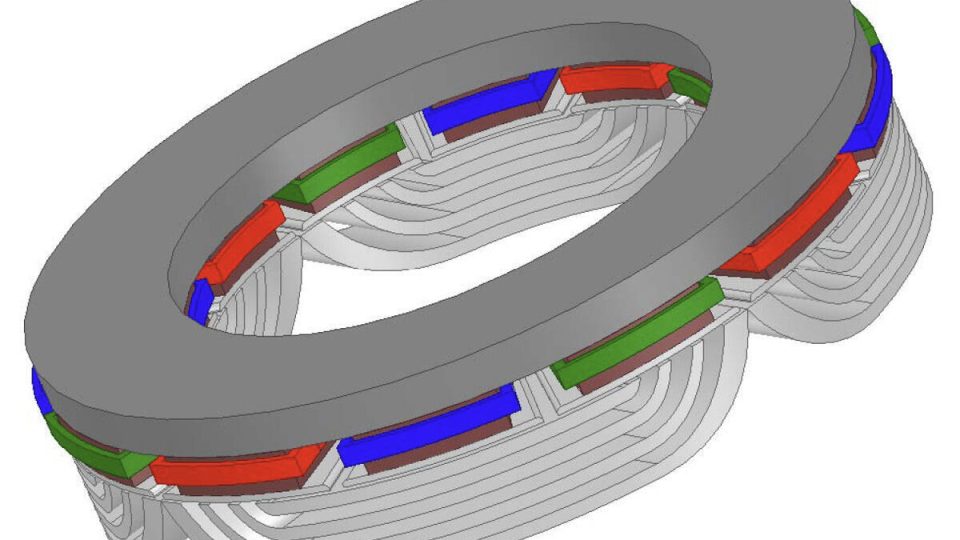

Twin Disc: heavy-duty REPTO has enhanced horsepower

For generations, companies have relied on Twin Disc’s tough and reliable heavy-duty industrial equipment, like the AM080 Rear Engine Power Take-Off (REPTO) drive.

This REPTO drive has a maximum power rating of 1,533 hp (1144kW) at 2,200 rpm. It’s built for severe applications, including driving hydraulic pumps, grinders, crushers, dredgers, chippers, shredders and drills. It complements a full system of Twin Disc products that work in conjunction with each other including power takeoffs, marine gears, and transmissions.

A key enhancement of the AM080 is its high-power capabilities. Each pump tower has a 400 hp (298kW) maximum capacity and a combined 450 hp (336kW) capacity for both towers.

The drive is rotatable by 0°, 45°, 90°, either clockwise or counter-clockwise and 180° which makes it adaptable for clearance in any installation. The pads and splines are easily interchangeable in the field to accommodate varying pump sizes.