FEV: Towards Tier 5 and the Decarbonization of Off-Highway Powertrains

FEV outlines its roadmap to meet future Tier 5 requirements, combining advanced combustion, upgraded aftertreatment, hybridization and hydrogen conversion to achieve ultra-low emissions and sustainable off-highway powertrains

At the Non Road Powertrain & Fuels Europe 2025 conference, Thomas Körfer, Group Director Diesel Systems at FEV Group, outlined the company’s technical vision for future non-road engines, highlighting the challenge of balancing carbon neutrality, ultra-low emissions and cost effectiveness.

Tier 5 Regulations under the FEV lens

The upcoming Tier 5 regulations in the United States will demand a 90% reduction in NOx emissions and a 75% cut in particulate matter compared with Tier 4 Final limits, while also introducing CO₂ caps and OBD requirements. Real-world compliance and the new Low Load Cycle (LLC) test will require more advanced heat-up strategies and upgraded aftertreatment systems.

According to FEV, enhancements to the exhaust aftertreatment architecture will be essential for compliance with the NRSC cycle, while maintaining sufficient SCR temperature under low-load conditions will be a key focus area for future designs.

Optimized combustion architectures

For diesel engines targeting Tier 5 compliance, Körfer emphasized the need for optimized combustion architectures, EGR-tolerant designs, and advanced catalyst formulations to ensure both efficiency and durability. Rapid catalyst heat-up and new control logics will help maintain high conversion efficiency even during cold-start conditions, a known weak point in real-world operation.

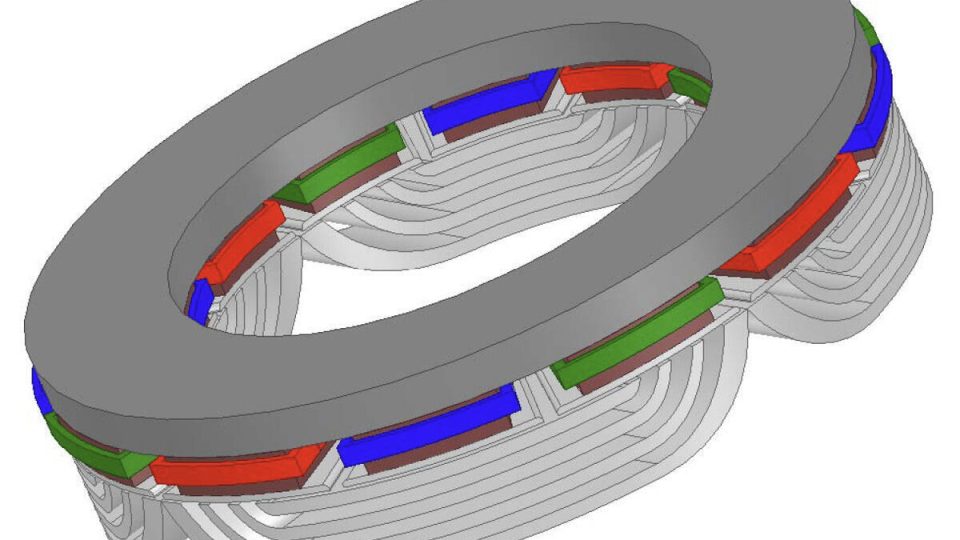

From an operational standpoint, FEV noted that fuel efficiency gains become increasingly relevant in total operating costs (OPEX) as engine power grows, while purchase price remains the dominant factor in the lower power range. Mild hybridization therefore represents a practical step forward, offering fuel savings of up to 30% in favorable duty cycles, while preserving overall system robustness and simplicity.

FEV also presented its technology roadmap for converting conventional diesel engines to hydrogen combustion, using a 2.5-liter base engine as a development platform. Key modifications include cylinder head redesign, direct hydrogen injection, optimized combustion chamber geometry, and improved charge motion management.

CFD-based virtual development enabled optimization of mixture formation and suppression of abnormal combustion, allowing the first-generation H₂ engines to combine carbon-neutral operation with near-zero pollutant emissions.

In conclusion

FEV identifies advanced combustion concepts, upgraded EATS architectures, hybridization and hydrogen conversion as complementary routes to “square the circle” of future off-highway powertrains—delivering high efficiency, regulatory compliance and long-term economic sustainability.