WAE Technologies at JSAE annual congress in Yokohama

WAE, the world-leading technology and engineering services business, showcased an advanced automotive battery solution at a leading automotive engineering conference held by the Society of Automotive Engineers of Japan.

WAE, the world-leading technology and engineering services business, showcased an advanced automotive battery solution at a leading automotive engineering conference held by the JSAE, Society of Automotive Engineers of Japan.

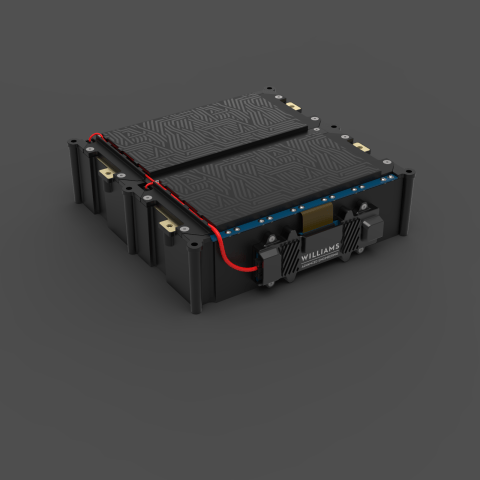

JSAE (Yokohama 24-26 May) saw the world’s leading automotive technology companies come together. At the event, WAE showed its Scalable Battery Module (SBM), which utilises WAE’s proprietary “Sense Chain” architecture to eliminate the replication of electronics, enabling independent scaling of voltage and capacity and the realisation of bespoke battery concepts in record time.

Revolutionising rapid and flexible battery development, WAE’s modular toolkit enables automotive customers to create custom pack and sub-pack systems faster than ever, supporting low-medium volume electric vehicle developers across a range of industries. Each module is 1.08kWh with a voltage of 50V Max, 43V Nominal with an energy density of >240Wh/kg.

Rob Millar, Head of Electrical at WAE, commented: “We are delighted to be showcasing our Scalable Battery Module at JSAE. This innovative new technology offers greater flexibility and speed to market for customers across a wide range of sectors and is yet another example of WAE’s wide roster of cutting-edge electrification solutions for the automotive market.”