Kohler wins DIESEL OF THE YEAR 2022

New KSD engine series brings the Diesel of the Year award back to Kohler for the third time.

Diesel of the Year is back at Kohler, winning the award for the third time in ten years with the new KSD 1403TCA engine. It had already won the award in 2012 with the KDI 2504TCR and in 2015 with the KDI 3404TCR SCR.

DIESEL magazine, which has been one of the leading specialist magazines in the sector in Europe since 1986, awards this prestigious title each year to the most innovative diesel engine. Today Kohler is proud to win the Diesel of the Year 2022, celebrated with a ceremony in the museum at its historic headquarters in Reggio Emilia, in its evocative gallery which displays some of the engines that have marked the history of the company.

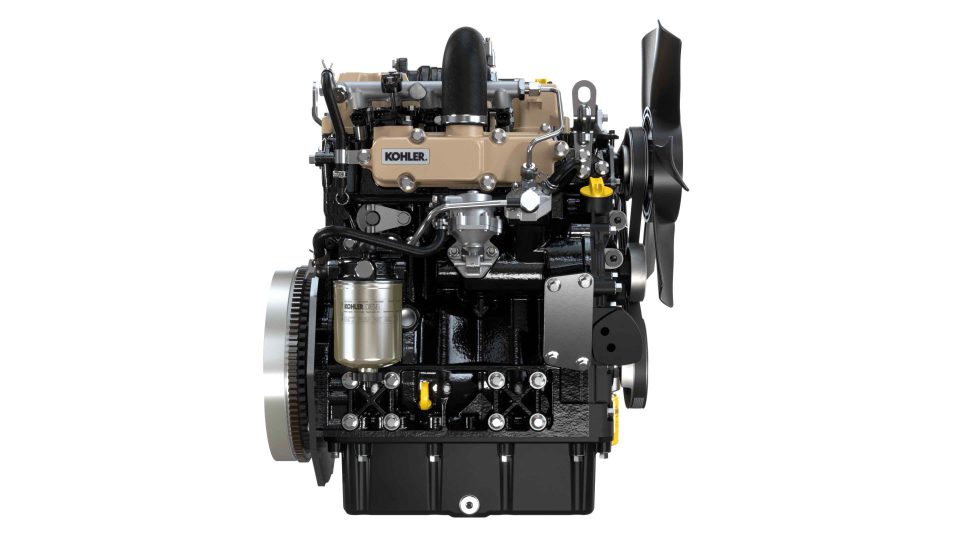

The award-winning engine is part of the new KSD (Kohler Small Displacement) engine series, designed to adapt to all geographical areas, comply with all regulations worldwide, and be compatible with all types of machines.

The KSD series is the result of a totally market and customer-oriented approach. It is simple, as it can be easily integrated with the increasingly complex electronic systems of industrial machines, which are constantly evolving. It is advanced, as it allows different customisations for all work cycles, as well as offering the possibility of data exchange with a reduced number of physical connections. It is versatile, being adaptable to the machines without need for modifications or redesigns.

The 1403TCA, which stands for Turbo Common Rail with Aftercooler, is one of three engines in the KSD range, which also includes the 1403 Turbo Common Rail and the 1403 Naturally Aspirated.

This version boasts a peak torque of 120 Nm @ 1400 rpm, a displacement-to-torque ratio competitive with engines of the same displacement but with outputs between 30 and 42 kW that need aftertreatment systems. The sub-19 kW engine complies with current global emissions regulations: EU Stage V, US Tier 4 Final and, by the end of this year, also China Stage IV. Consumption is reduced by optimising engine speed and controlling the hydraulics. Service intervals are maximised and total cost of ownership is low, thanks also to smart prognostic and diagnostic functions.

“Remember recent prophecies about Internal Combustion Engine’s premature burial? […] they were wrong, and diesel still has a long future in front. The KSD Series is a demonstration of this. The most intimate reason for the DOTY 2022 is precisely in the audacity to have invested in such an engine platform” declares Fabio Butturi, Editorial Coordinator at DIESEL. “The Diesel of the Year’s jury also appreciated the engine’s versatility and elasticity of features and configurations to simplify installation by OEMs”.

“We are enthusiastic and honored to receive this prestigious award now, for the third time in ten years. It is the demonstration of Kohler’s strong commitment to the business and continuous investment in new engines” comments Vincenzo Perrone, President of Kohler Engines. “All of what has been accomplished is thanks to the hard work of our world-class global team. Words can’t express how proud I am of the collective efforts made by all our associates in making KSD a reality. It is through their dedication, perseverance and teamwork, not to mention expertise and collective know-how, that this project came to fruition and has been and will continue to be a great success”.