MAN at Agritechnica 2025: Not Only Engines

MAN Engines at Agritechnica 2025 with product updates for the agricultural machinery: Reman, BatteryPack and TGS Truck

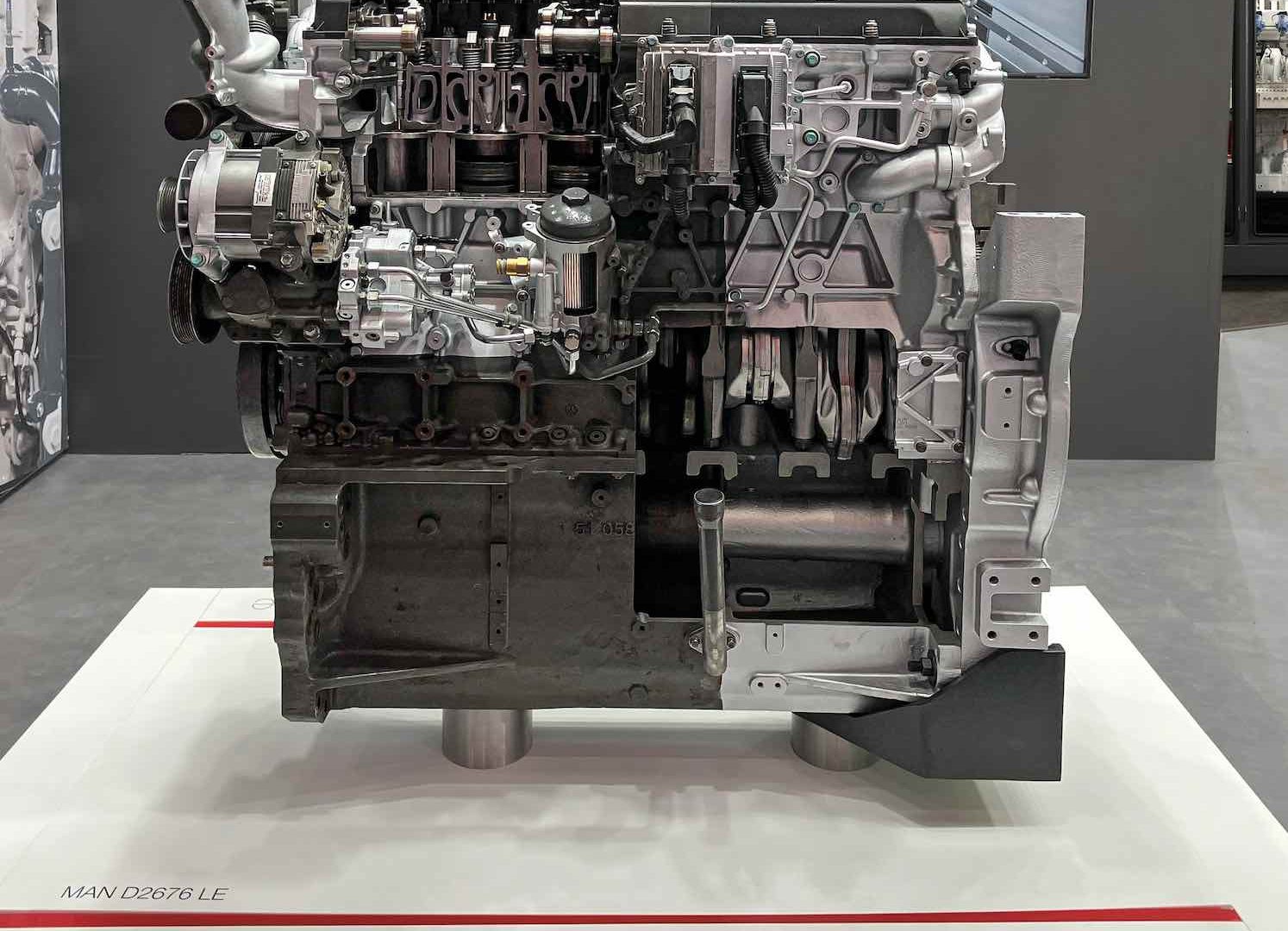

We are completing the overview of what MAN Engines will bring to Agritechnica 2025, which is about to open its gates to exhibitors, operators, and visitors. We talked about the engine testimonials HERE. Now it’s time to continue with the rest. We’ll stick with the internal combustion engines and start again with the D2676 engine with oil pan support structure that has been overhauled by the MAN Remanufacturing process.

MAN Reman at Agritechnica 2025

This unit is used in the Fendt 1000 Vario and is offered by AGCO as a REMAN engine – recognizable by the corresponding logo on the exhibit. The cutaway model MAN D2676 on display vividly illustrates the differences between a used engine and a fully refurbished one. In addition, the MAN portfolio for original factory-remanufactured engines includes other types – from D1556 to D4276 to D2862 – for a wide range of applications such as tractors, forage harvesters, combine harvesters and shredders.

As the parent company of the MAN Engines business unit, MAN Truck & Bus has more than three decades of experience in the professional remanufacturing of engines for a wide range of applications – from commercial vehicles and stationary units to off-road and maritime applications. At the Engine Competence Center in Nuremberg, used engines are repaired with the highest precision and according to the latest technical standards.

Especially for farms, contractors and municipal facilities, a factory-refurbished engine is a sensible alternative for continuing to operate existing machines in a resource-saving and cost-efficient manner. Tailor-made integration into existing systems takes place without additional adaptation effort.

And BatteryPack…

The NMC cell chemistry (nickel-manganese-cobalt) used enables a particularly high energy density with low weight and compact design. This allows even demanding application scenarios with limited installation space and high performance requirements to be optimally implemented.

According to the company, a key feature of the MAN BatteryPack is its durability. The intelligent battery management system permanently monitors the condition of the individual cells and ensures an optimal temperature range at all times thanks to a sophisticated heating and cooling system.

The battery packs will be produced at the Nuremberg site, where MAN Truck & Bus is making targeted investments in the expansion of battery production, thus creating the technological basis for the mobility of the future. The production of different form factors of the MAN BatteryPacks enables flexible application in a wide variety of customer applications and vehicle concepts. At the end of production, each individual BatteryPack undergoes a comprehensive “end of line” test, in which around 400 test parameters are recorded and documented.

The development and production of the MAN BatteryPack benefits significantly from the transformation of the MAN plant in Nuremberg, which today functions as a center of excellence for battery and combustion engine technology. In addition to battery production, the latest generations of combustion engines – from diesel to natural gas and biogas to hydrogen – are also developed and manufactured here. With investments of around half a billion euros in the Nuremberg site, MAN Truck & Bus is clearly committed to Germany as a location for innovation and to the sustainable mobility of the future.

TGS 18.540 4×4 BL SA

MAN Truck & Bus will be presenting a truck specially designed for agricultural requirements at its joint booth: the MAN TGS 18.540 4×4 BL SA. The agricultural truck on display is classified as an agricultural tractor and, thanks to permanent all-wheel drive, off-road driving programs and soil-protecting wide agricultural tires, offers maximum usability even under difficult ground conditions. The load-sensing hydraulic system and the trailer bracket with forced steering enable precise and safe control of agricultural equipment and trailers.

The driver-focused cockpit with intuitive operation, the Professional instrument cluster and the MAN SmartSelect system ensure a modern and ergonomic working environment. For additional safety and comfort, a lane return assistant, reversing camera system, ACC Stop and Go adaptive cruise control and the MAN PriTarder high-performance engine brake are installed, among other things.

With a fifth wheel coupling with integrated lubrication and a trailer trestle for agricultural trailers, the MAN TGS is suitable for use with both semi-trailers and trailers. Approval as an LOF vehicle (agriculture or forestry) also enables advantages such as the elimination of the Sunday driving ban and the tachograph requirement.