Cummins opens brand new facility in Poland

Cummins is to open a state-of-the-art high-horsepower engine rebuild centre in Krakow, Poland. The new site, set to be fully operational at the end of this year, will be the company’s first such specialist rebuild facility in Europe.

Cummins is to open a state-of-the-art high-horsepower engine rebuild centre in Krakow, Poland. The new site, set to be fully operational at the end of this year, will be the company’s first such specialist rebuild facility in Europe. This USD 10 million investment will enable Cummins Poland to provide strategic support for its customers throughout the region, not only in the specialised engine rebuild process but also supporting local customers throughout Poland with its considerably extended distribution and warehousing capabilities.

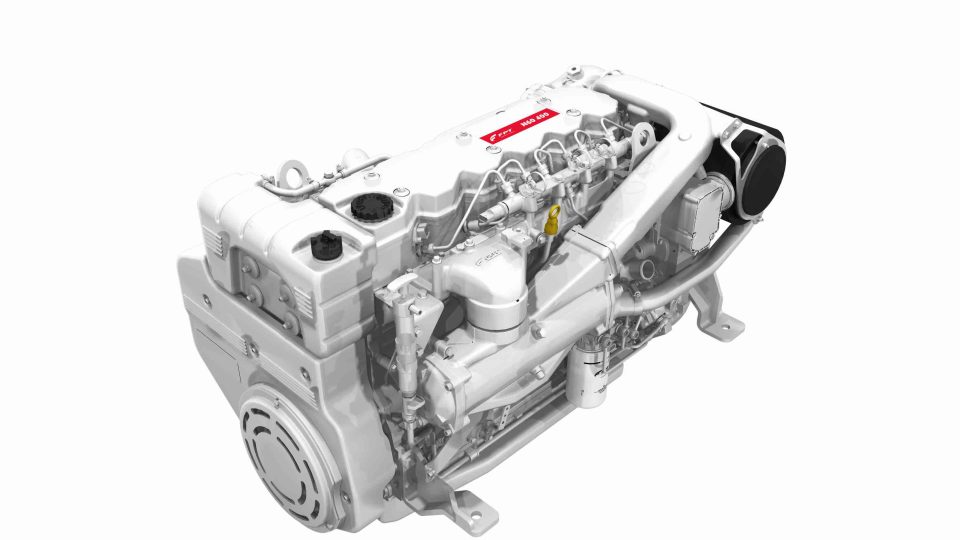

The new 4,600 m2 facility will help meet growing customer demand for such specialised engine rebuild services. It will also deliver a better response to the differing needs of Cummins customers across Europe, supporting them with the highest quality maintenance service, improving engine uptime, increasing engine efficiency, and driving down costs. It will complement the company’s global network of dedicated high-horsepower engine rebuild sites, typically suited to engines 19 litres and above in size, including Cummins renowned QSK19, QSK38, and QSK60 engine models. Furthermore, the new centre will be capable of overhauling and rebuilding smaller engines, including those from mid- and heavy-duty ranges. Since they operate in some of the harshest working environments, the rebuild process – including complete disassembly, cleaning, inspection, the replacement of major components, design improvements, and testing – is dedicated to extending the life of the original engine. In many cases, these steps can also enhance the engine’s fuel efficiency and performance, thus making the product life cycle more sustainable.

“This is a significant step in increasing Cummins’ presence in Poland and other European countries, enabling us to meet the demand for engine rebuild services across several market segments more effectively. Once the rigorous engine rebuild process is complete, a product can be considered ‘as new’, delivering performance that is the same or better than the original engine, so the investment is sure to prove beneficial for our current and future partners. This is also a strategic move for Cummins globally in that it significantly expands the range of services in the region while expanding storage and distribution capacity, including a six-fold increase in warehouse space,” says Marek Matuszewski, Country Leader for Poland, the Baltic States & Ukraine at Cummins. “The location of our company’s first centre of this kind in Europe is also no coincidence. It is situated close to the international airport in Krakow and alongside a major highway connecting the city to other European destinations, so it has excellent road, rail, and air transport links to other key countries for us and our customers. Moreover, due to the presence of great technical universities in the city, more world-class specialists will be able to join our team,” he added.

The new centre will feature numerous sustainable solutions, including a high-tech microbiological wash bay reusing 100% of water, the installation of solar panels, allowing Cummins to use its own green energy as well as charging points for electric vehicles. In addition, it will be equipped with innovative systems such as two 15-tonne overhead cranes, jib cranes, a test cell with an engine dynamometer, a paint booth, and a bake-and-blast cleaner. On top of that, the new site is to have two disassembly bays, four high-horsepower and three mid-range/heavy-duty assembly bays, and a MILLIPORE testing stand. Such specialised capabilities of the centre will therefore naturally generate additional interest in Poland among businesses from outside the country.

Cummins, which has been operating in Poland for almost 30 years now, at present has four sites here, in Krakow, Gdansk, Lubin, and Lomianki, all strategically located so that they can be readily accessed by customers from the whole country. The newly-built plant is replacing the company’s current facility also located in Krakow and will extend its present operational and rebuild capabilities. As a result, administrative and financial specialists, as well as engineers, will join the existing team this year.