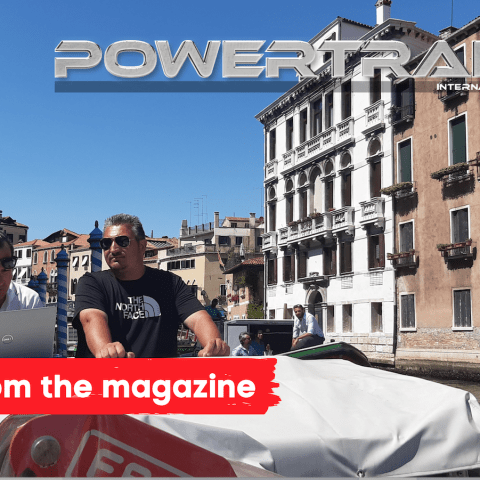

Bimotor: what if Stage V was the answer?

Bimotor tested two FPT Industrial engines in Venice with PEMS, one Stage V, the other non-compliant. Stage V engine significantly cut emissions. “Nobody here is against electrification, but what can you do then? Should you double the fleet and halve navigation times to electrify all the boats?”. Read the full article in the September issue of Powertrain International.

Venice, squeezed in the grip of depopulation, high tide floodings and pollution. It would be the perfect candidate for electrification, if it wasn’t for the local issues linked to navigation and the installation of charging stations. Yet there seems to be a way, and they know which at Bimotor. A solution that may sound like heresy but is real: Stage V. Bimotor’s CEO Filippo Brunero told us about the comparison test between a Stage V small freight transport boat, known as mototopo (literally “motormouse”) and a non-emissionized one.

“Could someone please explain to me how a steamer could work some 14 hours a day in full electric mode? We crunched the numbers and with these working conditions it would just carry batteries around, not people. So why not show that diesel can still give its contribution in such a complex environment? With this in mind, on the 3rd of June at a conference on the ecological transition we transcribed an hour of steamboat operation into 3600 Excel lines – such is the amount of the parameters we measured. While navigating, we found out the two water bus lines we selected from Venice’s public transport company ACTV had different profiles. A steamboat’s mean absorption on its daily mission is 50 kW, which equals to 220 kg of diesel stored aboard or to 800 kWh. We believe Stage V is the ideal recipe. In July 2021 we undertook a comparative test between the emissions of two ‘motormouse’ boats with exactly the same weight and displacement, equally powerful engines and different emission standards. The one named Claudia was equipped with a non-emissionized NEF 6.7 150, 110 kW, very commonly used in the Lagoon due to its reliability. The one known as ‘El Nonno Kille’ had, instead, a 125 kW Stage V FPT N40. We installed a PEMS – a portable emission measurement unit – and we took a nice tour of the Lagoon. From Marghera, alongside the Ponte della Libertà, cruising in the Canal Grande in an eerie silence, traveling at the lowest speed, down to the Giudecca Isle. That same day the Finance Ministers and Central Bank Governors gathered there for the G20. Same speed, same traffic conditions, we took the Stage V in the morning and the non-emissionized 6-cylinder in the afternoon. Leaving aside PM10 that can’t quite obviously be isolated under these conditions, we realized that HC and CO emissions were significantly lower. On average, with same rating and mission cycle, the N40-170 had halved the levels of nitrous oxides, carbon monoxide and unburnt hydrocarbons. We noticed we could even curb CO emissions further: the engine needed more air as the engine compartment is too tight. Once we opened the hood, indeed, carbon monoxide emissions plummeted. Stage V is a must also with hybrid solutions.”

What other arguments could you provide against politically driven decision-making?

“We took Venice as our context, since we have a partnership there with Vulkan to hybridize steamers. We provide the ICE, which is not used to drive the propeller but to keep batteries within a given range so as to maximize their useful life. We have downsized engines – from 8.7 to 6. 7 liters, Stage V, which is not a ‘low cost’ application. This is a sustainable answer to the needs of workboats. Series hybrids requires a lot of power electronics. In our cycle the mototopo’s absorption is around 10-15 kW outside the Canal Grande. If used for 5 hours a day and leaving performance aside, we’ll need 65 kW/h of installed power onboard, which means 80 thousand euros worth of batteries. And we did not even mention charging time yet. What could we say to the Mayor of Amsterdam other than his city does not live on waters, unlike Venice? On the Lagoon, public services and private transportation depend on boats.”

TO READ THE FULL ARTICLE CLICK HERE OR DOWNLOAD THE PDF